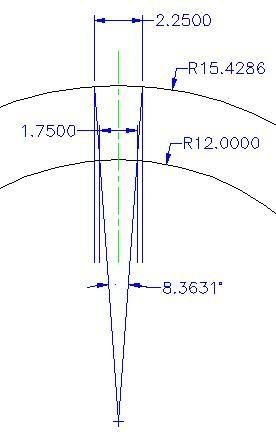

Perhaps someone else should check my math, but I'm fairly certain that if you wanted a 12" radius at a 1.750" nut and a 2.250 width 12th fret, you would need a 15.428" radius at the 12th, requiring a 15.662 degree angle if you wanted a straight board under each string coming off a axle mounted radiusing jig. My numbers would put a 32 degree angle as leaving notable relief under the outer strings if the center were straight.

We seem to be at about 2:1 difference with our numbers, so it's likely a simple formula glitch on one side, but I'm fairly comfortable with my results (keeping it mind, these are 1:30 AM results

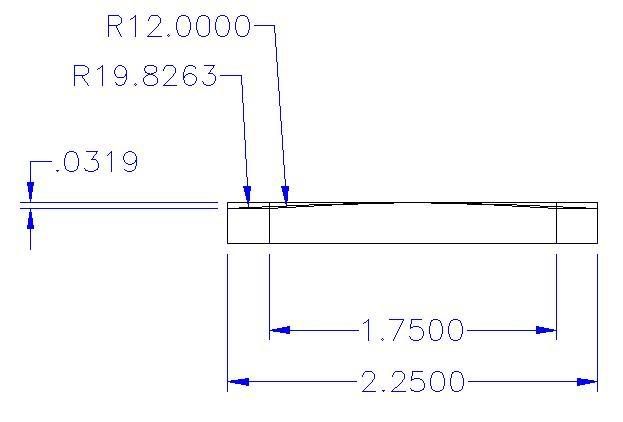

If using an axle-style fingerboard shaper, you would need to maintain a constant section of the circle as it widens in accord with the fingerboard width to keep a line under each string straight. Starting with a 12" radius and 1.750" nut width (or cord), this would leave you with a 8.363 degree section of the circle. That same 8.363 degree section at a 2.250" cord at the 12th fret would leave you with a 15.428" radius at that point. This in turn would result in a 15.662 degree angle on a 25.4" scale board (no compensation to actual string length is considered here, but I doubt it would affect more than 1/8 degree difference).

I'm wondering if your calculations are giving you the entire angle of the cone, rather than the half of it that would be required for setting up the jig. Again, I would love it if someone double checked my numbers, but I think they are on. Then again, I'll never rule out a

![Mad [headinwall]](./images/smilies/headbangwalluf8.gif) moment if someone were to correct me.

moment if someone were to correct me.

)

)

![Thumbs Up [:Y:]](./images/smilies/smiley20.gif)