This one came in a few weeks ago, immediately after leaving another area repair shop. It's a '42 Gibson Southern(er) Jumbo. First year made, only year with the firestripe pickguard, maple neck reinforcement (war era, no truss rod), still had mahogany neck and neck block before they started using maple and poplar soon after. Low 2000's batch number (I think 2118), scalloped braces. This was the highest model Gibson made at the time, and were built by about a 10% skeleton crew during the war era, where Gibson kept only their best luthiers to build guitars. Phenomenal guitar, valuable guitar, and certainly worth preserving

When it entered the previous repair shop, it was certainly beaten and played, had it's share of scars, and had been refretted with jumbo wire, which appears to have been a good professional job. A fair amount of cleated cracks from years of use, replaced tuners, one replaced and a few cracked pearl fingerboard inlays, not sure about if the neck was ever previously reset (probably not), but the bridge was original. These guitars with the heavy radius tops are generally so stable that they don't often need neck resets, though at this point I have no way of really knowing if it really did here or not. In any case, the other shop did do a neck reset, and here are the results.

Heel cap fit - that's kind of shoddy

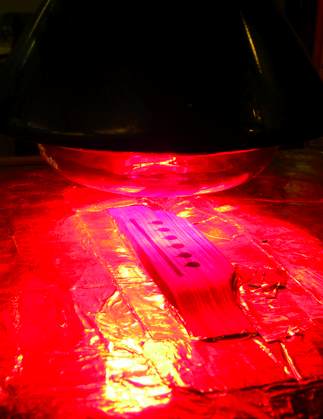

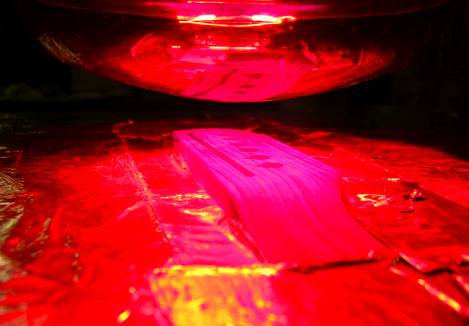

Looks like it got a bit hot during removal - ooh, that wasn't there before.

But at least they got the angle up. and after some touchup around the extension, they even threw in a beautiful new bridge.

A beautiful new cocobolo bridge. How nice... And just to make sure it wouldn't need another neck reset any time soon, they kicked the angle back a bit more, and made the bridge about .400" tall (way better than those old 1/4" Gibson bridges, right?). The old bridge appears to be gone now.

Let's get another look at that beauty - just look at those Gibsonesque lines.

Thankfully through all this work, they left the original bridgeplate intact - well, intact and still glued on in front of the pins anyway.

I'm quite thankful they didn't decide to pull the bridge plate, as there's no telling what damage that may have brought.

So that's how it came in. Now though they did reset the neck at too high an angle, thankfully it wasn't as bad as it originally looked. They greatly overcompensated in the replacement bridge height. The action was quite high, though there was still quite a bit of buzz at a decent size hump at the extension.

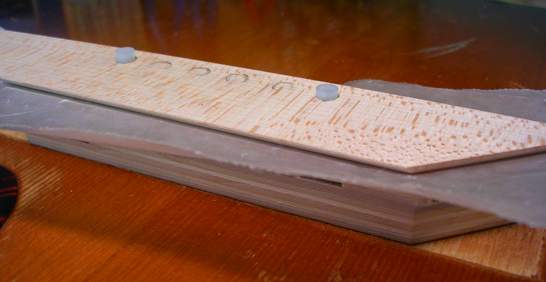

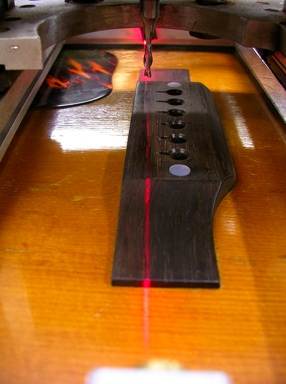

After discussing options with the customer, we decided that the neck angle and cosmetic damage is now what it is, and we weren't going to attempt to bring it back down. After leveling the frets, I felt I could get a bridge in the .300"-.320" range, with about .160" saddle clearance at the center, which I felt this top could handle just fine. So it's a new Brazilian bridge and saddle, new bridge plate, and fret leveling. I'll put an abbreviated summary of the repairs over a few more posts.

![Thumbs Up [:Y:]](./images/smilies/smiley20.gif)

![adulations [clap]](./images/smilies/smiley32.gif)