[QUOTE=Don Williams] Once again, I can't view the pictures in Tim's post on the other forum. Rats.

[/QUOTE]

Don,

This is a copy of Tim's post on the other forum. I hope you can see the pictures now.

[QUOTE=Tim McKnight] I have recently switched over to building "Double Sides" on my guitars. It is a lamination process but since the word "lamination" is associated with cheaper guitars I prefer to call them double sides. Why double sides, you may ask? Certainly NOT because it is any easier. Quite the contrary, it is a royal pain in the .... rear.

Double sides have many advantages over single sides: They are EXTREMELY rigid, are virtually crack proof, they will not move around under humidiy or temperature changes and they provide a much stiffer and more stable rimset to support the top, back and neck. They are about the same thickness as a one piece side set and only slightly heavier due to the added weight of less than 3/4 of a liquid ounce of structural epoxy resin.

There may or may not be a tonal advantage. I don't have enough of them in the field yet to tell. However, just tapping on the rimset, it will ring just as loud and with as much sustain as a solid one piece side set. Maybe even slightly more so in both respects.

Why go to all of the extra work? Well, I am always looking for a way to improve each and every guitar that I build. I truly believe this design has many advantages over a single thickness side set that it warrants the extra work on my part for the behalf of my customers. Since I put soundports in the majority of my guitars the double sides will also eliminate any structural or cracking issues that could arrise due to unplanned impacts or abuse.

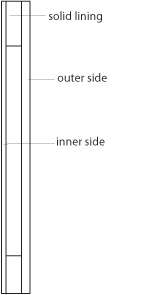

A thin inner side and a thicker outer side are bent at the same time in my Fox style bender. The tools that I use are a solid inner bending form of the final shape body I plan to build, 18 C-clamps, two strips of wax paper an outer clamping caul and 3/4 ounce of liquid two part epoxy "super hard" resin.

The resin is squeegied onto the outer surface of the inner side (Honduran Mahogany in this case) and the inner surface of the outer side (Quartersawn Curly White Oak). Say that 10 times really fast.

Both inner and outer sides now have an equal amount of resin applied and are ready to be joined.

First a strip of wax paper goes down so the side set will release from the form then onto the form the double sides go.

Another strip of wax paper goes on top of the outer double side and then the outer clamping caul goes on. Two clamps are snugged up at the waist to hold the side set together while I line up the ends. The resin is pretty messy and slippery and the side halves try to skid around under the clamping force.

The remainder of the clamps go on while keeping a close eye that the sides remain perfectly aligned as gradual clamping force is applied. Excess resin begins to ooze out so I have to wear rubber gloves and put plenty of newspaper down to contain the mess.

24 Hours later the resin is rock hard and the side set is removed from the form. You can see how the resin was forced through the wood pores on the inner side set.

Even the exterior side set shows signs of resin permeation. This sands off and does not effect the final finish process.

As you can see the Double Side set now holds its shape perfectly and there is absolutely no tension in the side set. We [luthiers] all aim to build our guitars with little or no tension in the wood so there are not any undue stresses placed on any joint of the guitar.

Here the finished double side side set rests perfectly in the side form with no signs of springback or twisting. These completed side sets are a joy to work with. They are so stiff and not the least bit fragile like the floppy side sets I was acustomed to working with previously.

This pictorial is by no means meant as a slam or to degrade other luthiers work. This is just a new way that I have found that works well for me. There are several luthiers who are using this method so it is not something new that I have invented or that is revolutionary. Ervin Somogyi, Michael Bashkin, Michi Matsuda, Mario Beaureguard and many others have found this process successfull for them. It is just a path that I have chosen to pursue and to see where it leads me next.[/QUOTE]

|