Steve, do you meen to cap the x brace?

I do that on every guitar, I think that most people do.

If this isn't what your talking about, than forget my post, but please elaborate

| Official Luthiers Forum! http://w-ww.luthiersforum.com/forum/ |

|

| Fillet the X brace? http://w-ww.luthiersforum.com/forum/viewtopic.php?f=10102&t=10299 |

Page 1 of 2 |

| Author: | Steve Saville [ Wed Jan 10, 2007 1:11 pm ] |

| Post subject: | |

In one of the Somogyi discussion I asked about adding some small fillets to the X brace. It seems that this joint is vital to the guitar and some small fillets would add a lot of strength without adding much weight. Has anyone done this? Any thoughts/observations? |

|

| Author: | Dickey [ Wed Jan 10, 2007 1:19 pm ] |

| Post subject: | |

What's a fillet? |

|

| Author: | peterm [ Wed Jan 10, 2007 1:20 pm ] |

| Post subject: | |

Fillets? You mean the piece on top to reinforce the joint? |

|

| Author: | Rod True [ Wed Jan 10, 2007 1:21 pm ] |

| Post subject: | |

Steve, do you meen to cap the x brace? I do that on every guitar, I think that most people do.

If this isn't what your talking about, than forget my post, but please elaborate  |

|

| Author: | JJ Donohue [ Wed Jan 10, 2007 1:33 pm ] |

| Post subject: | |

I use it...it works |

|

| Author: | SteveCourtright [ Wed Jan 10, 2007 2:21 pm ] |

| Post subject: | |

In welding, when you join two things with a fillet, it refers to a U shaped part of the weld which fills in the interior angle of the joint. Fillet brazing then, creates nice smooth weld transitions where things join together at an angle. I assume Steve means a U shaped bead of glue in the interior angles of the X of the X brace. Right Steve? |

|

| Author: | Steve Saville [ Wed Jan 10, 2007 3:47 pm ] |

| Post subject: | |

[QUOTE=Rod True] Steve, do you mean to cap the x brace? If this isn't what your talking about, than forget my post, but please elaborate  [/QUOTE] No, I don't mean to cap. I didn't explain it very well. [/QUOTE] No, I don't mean to cap. I didn't explain it very well.

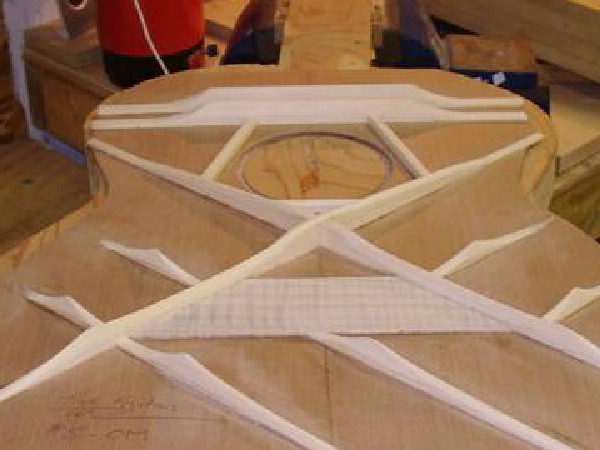

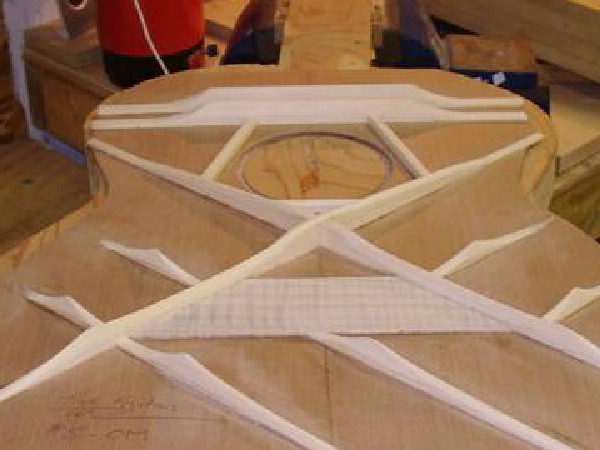

I mean to add a radius to the joint like in the drawing below. It would be made from the same wood as the X brace and glued in place. Fillets add lots of strength.

|

|

| Author: | Steve Saville [ Wed Jan 10, 2007 3:49 pm ] |

| Post subject: | |

[QUOTE=SteveCourtright] In welding, when you join two things with a fillet, it refers to a U shaped part of the weld which fills in the interior angle of the joint. Fillet brazing then, creates nice smooth weld transitions where things join together at an angle. I assume Steve means a U shaped bead of glue in the interior angles of the X of the X brace. Right Steve?[/QUOTE] Close, but not just glue. See my post above. |

|

| Author: | Rod True [ Wed Jan 10, 2007 4:35 pm ] |

| Post subject: | |

OK.....thanks for the clearification and picture Steve. I've never seen that before, but it certainly would add a lot of strength to the x joint. I guess the real question is.....do we really need it? |

|

| Author: | Rod True [ Wed Jan 10, 2007 4:38 pm ] |

| Post subject: | |

So taking a second look at the picture of Ervin's guitar on the other forum

We can see that there aren't fillet's on his, but that certainly doesn't mean it can't be or couldn't be done, just have to ask are self if it needs to be.... |

|

| Author: | JJ Donohue [ Wed Jan 10, 2007 4:49 pm ] |

| Post subject: | |

Errata: I don't use fillets. However I love to eat filets... especially salmon and mignon

It's late and time to go to bed! |

|

| Author: | Howard Klepper [ Wed Jan 10, 2007 5:06 pm ] |

| Post subject: | |

They would IMO strengthen the joint in directions in which it is not stressed much. |

|

| Author: | burbank [ Wed Jan 10, 2007 5:08 pm ] |

| Post subject: | |

Here's my 2 centavos. If the stresses were parallel to the top, going radially around the x, as if they were opening and closing the x, the fillet would be a good thing. But the stress on the top is almost all perpendicular to the top and little benefit would be had, I think. eidt: I guess Howard posted his clear and succinct reply as I was plunking out my usual wordy stuff. |

|

| Author: | Steve Saville [ Wed Jan 10, 2007 5:09 pm ] |

| Post subject: | |

[QUOTE=Rod True] I guess the real question is.....do we really need it?[/QUOTE] Rod, Do you think the real question could be.....does it improve the sound of the guitar or make it more durable without adversely affecting sound? |

|

| Author: | j.Brown [ Wed Jan 10, 2007 5:20 pm ] |

| Post subject: | |

It seems that it would increase the strength of the X joint to a point where it may not flex like we want it to. Strength, to a point, is a great thing...beyond that, it hinders the movement of the sound. Seems like a lot of work to add the fillets. If I'm wrong, it would surely be the first time.

-j. |

|

| Author: | Rod True [ Wed Jan 10, 2007 5:22 pm ] |

| Post subject: | |

Well......it could be the real question, and sounds like it's yours

I don't know that answer to that  but I certainly can speculate. but I certainly can speculate.

I would think that this area of the bracing doesn't vibrate all that much as it is probably the stiffest location on the top, other than the glue joint between the head block and the top plate, so I suspect that you really wouldn't see any difference in sound with or without it. Would it make it more durable....there are lots of 60+ year old guitars out there without it. |

|

| Author: | Colin S [ Wed Jan 10, 2007 8:37 pm ] |

| Post subject: | |

[QUOTE=Howard Klepper] They would IMO strengthen the joint in directions in which it is not stressed much.[/QUOTE] Exactly, as usual Howard is right. I see no point in them. Colin |

|

| Author: | Steve Saville [ Thu Jan 11, 2007 3:02 am ] |

| Post subject: | |

I thought about this while watching the Somogyi video while he stressed how important it is to have a great joint there. I think he mentioned that it was vital to have a well executed joint. Perhaps a couple of fillets could make a mediocre joint good and a good joint even better. Just thinking a bit. It doesn't seem like it would hurt anything. Perhaps it won't help. But what if it does? I only know one way to find out. I'll ask Ervin.

|

|

| Author: | Howard Klepper [ Thu Jan 11, 2007 6:23 am ] |

| Post subject: | |

Agree with SteveS's last post. The lap joint has one strong joining surface and four joints of end grain. While it doesn't need any of the kind of extra resistance to the X arms opening or closing that the fillet gives (and would be why it is used in a weld), the pieces could be very small and thin and insure that the lap joint does not separate. It wouldn't be much work. Not that I have seen a lot of X brace lap joints separating, though, especially when capped. |

|

| Author: | Alan Carruth [ Thu Jan 11, 2007 7:44 am ] |

| Post subject: | |

If you look closely at that pic of Irvin's guitar, you'll see that it does have a cap over the open part of the box joint. Since the bridge torque tends to stress that area highly, some sort of cap is, IMO, nessecary. Even the round linen patch that many manuufacturers have used for years helps a lot. I recently put one on a Taylor that one of my students has, that developed the split out from the bottom of the box cut that is all too common in unreinforced ones. The brace tops were so narrow that it would not have done much good to put on a wood patch, but the linen one, put on with hot hide glue, seems to have worked well. The hot glue just sucks the cloth right in tight to the brace after it gels, and makes a surprisingly strong joint. |

|

| Author: | Terry Stowell [ Thu Jan 11, 2007 8:36 am ] |

| Post subject: | |

I once used a prefab brace set from Grizzly, and there was no way to put a cap on top. The X braces were radiused on the top, even at the joint. Not sure if they still do them that way. Anyhow, I think I should put a gauze patch on. Good idea. |

|

| Author: | Steve Saville [ Thu Jan 11, 2007 9:22 am ] |

| Post subject: | |

[QUOTE=fmorelli] .....I can see no reason for fillets (strength is in the wrong direction with a fillet.....[/QUOTE] Please don't think I'm picking on you, I'm not. Others have said pretty much the same thing. I don't understand the idea of strength in the wrong direction. A fillet doesn't add strength in just one direction. The fillets would enhance strength in the same directions that the glue inside the joint adds strength, yet no one would ever not glue the joint. I'm not trying to be argumentative. I'm not even bought into the need for fillets. I'm just trying to discuss and explore the idea. The objections to the idea, at least to me, don't seem as sound as the idea. Perhaps I'm a little slow and just don't get it. Perhaps I'm not. Who knows?

|

|

| Author: | JohnAbercrombie [ Thu Jan 11, 2007 9:41 am ] |

| Post subject: | |

[QUOTE=SteveS] I don't understand the idea of strength in the wrong direction. A fillet doesn't add strength in just one direction. The fillets would enhance strength in the same directions that the glue inside the joint adds strength, yet no one would ever not glue the joint. [/QUOTE] Steve: I'm with you on this. If you think of two fillets and the intervening brace wood, they are reinforcing in just the same way that a cap does. I've used fillets (epoxy) in boatbuilding (a lot) and they stiffen the joints in all directions. I don't see any problem reinforcing the 'X'- this is surely one of the most rigid areas of the entire top, so any reinforcement wouldn't be likely to degrade the sound much, I'd think. I may do a few tests with some scrap. This is interesting. Thanks for the thread. John |

|

| Author: | tony [ Fri Jan 12, 2007 3:29 am ] |

| Post subject: | |

Steve – I’m certainly no expert… but IMHO I think your idea has great merit and your reasoning for doing it is sound. Of course everyone who points out that the greatest strength from adding the fillets to the X brace would be where it flexes horizontally is 100% correct. But don’t let that notion overshadow the fact that strength is also being added on the vertical plane as well. It might not be the normal reason for using this method of joinery, but we shouldn’t deny its other benefits. To me, you are adding strength vertically by virtue of the additional glued surface used to mate the pieces - locking the two pieces more solidly together at the intersection. In my eyes it is kin to the principle that Alan uses when he mates his back plates with the faces to be mated having been planed on matching angles – more glued surface, added strength at the joint. The argument could be made that - everyone else in the world (figure of speech) planes the matching faces at 90 degrees – and there are guitars over 100 years old that have not failed. Is that a good reason for not adapting more sound construction methods? I think Evin would suggest that we should make our evaluation based on the strength gained against the additional weight we are adding. I don’t see any significant weight added by using fillets. And if the added strength makes it too stiff at the X brace, that only means other opportunities are presenting themselves – to shave more here or there,etc. Unless you are on a tight production schedule and budget, I say go for it. I see little chance for it causing a problem. And the fact that you have identified this little “thing” means your build will be unique – a little more “you” in it. And that would be a good thing – IMO. |

|

| Author: | Alan Carruth [ Fri Jan 12, 2007 9:29 am ] |

| Post subject: | |

Filippo wrote: "Since my X brace was (classic Martin) scalloped and equal height, I mixed wood glue and wood dust, and simply fill the gap until it was solid from top to bottom. Looks good, easily as strong now in both directions. " It may seem so, but it's not. We're talking about a 'box' or 'half-lap' joint here. If the brace is 6mm wide and 14mm tall, you cut notches in each brace 6x7mm at the crossing point, one notch in the 'top' of the brace, that faces toward the top plate, and the other in the 'bottom', that faces into the box. Being a good craftsman, you cut these tight, and glue the joint on all surfaces, of course. The notch that faces 'up' is bridged over by the wood of the plate. The notch that faces downward is open. Of course, it is filled in by the wood of the crossing brace, but that's only effective in resisting compression loads. On the completed guitar this part of the joint is in tension, since it's in front of the bridge, and the front edge of the bridge is pushing downward, trying to open the notch. In your filled joint, the only thing resisting that tension load is the glue and sawdust mix you put in it. Wood glue is not really very strong in tension, nor does it stick well to end grain, due, in part, to the shrinkage as it dries. So there's not much holding that part of the joint together. Once that lets go (and it will) you've got a situation where there is a lot of stress concentrated in a small area. This is because the stiffness of the brace goes as the cube of the height. At the notch the brace is only 1/2 as high as it is on either side, so it's only 1/8 as stiff. It 'wants' to bend a lot more right there. This puts a very high load on the wood just at the corner of the notch, where the stiffness changes suddenly, and it is not unusual for the brace to crack right at that point. Once it does that whole area of the top is much less stiff in that direction than it is supposed to be, and it dips down. I can't tell you how often I've seen this on old guitars, or even ones, like my student's Taylor, that are not all that old. You can also see the effect of that stiffness difference if you look at the way the 'free' plate vibrates. Ones without the patch over the joint have quite asymmetric modes, and they clear right up when you add that little patch. It's not as obvious on completed guitars, of course, but it probably makes some difference. As I say, for braces like those in kits that are pre-rounded, or tapered in width near the top, the cloth patch makes a surprisingly large difference. It's not as good as a wood patch, but it's sure better than nothing. |

|

| Page 1 of 2 | All times are UTC - 5 hours |

| Powered by phpBB® Forum Software © phpBB Group http://www.phpbb.com/ |

|