I've used an iron with foil underneath to remove a fingerboard before. Just be careful and watch the temp, I got mine a little too hot and bubbled the finish in one area.

| Official Luthiers Forum! http://w-ww.luthiersforum.com/forum/ |

|

| Removing a fingerboard http://w-ww.luthiersforum.com/forum/viewtopic.php?f=10102&t=10858 |

Page 1 of 1 |

| Author: | Michael McBroom [ Sun Feb 11, 2007 3:08 am ] |

| Post subject: | |

I just took a look over at frets.com to see how Frank Ford removes fingerboards. He uses a small silicone blanket, which I don't have, and don't plan on buying. I was thinking of using a clothing iron and just setting it on top of the frets. My only concern about doing it this way is that, since it's sitting on top of the frets, most of the heat is being transferred by the frets and there will be areas between the frets where much less heat is conducted down to the glue joint. I'm thinking about making up some shims out of aluminum foil to rest between the frets. I note that Frank Ford wraps his mini silicon blanket in foil for this procedure -- maybe to achieve the same result? So, what would y'all recommend? Best, Michael |

|

| Author: | Dave Rector [ Sun Feb 11, 2007 3:44 am ] |

| Post subject: | |

I've used an iron with foil underneath to remove a fingerboard before. Just be careful and watch the temp, I got mine a little too hot and bubbled the finish in one area.

|

|

| Author: | Dave Rector [ Sun Feb 11, 2007 3:44 am ] |

| Post subject: | |

Oh yeah, I didn't use any shims, just the foil and household iron. |

|

| Author: | David Collins [ Sun Feb 11, 2007 4:20 am ] |

| Post subject: | |

I've used silicone blankets for some things and heat cartriges for others, but for fingerboards and bridges I still prefer a heat lamp. I still feel it gives me the most control as where to apply and focus heat since there is no direct or radiant heat transfer. Since the light only causes heat where there is material to absorb it, aluminum tape and foil offers great control. It lets me run a 1/2" square over pearloid dots, or tape set 1/4" in along the binding and works quite well. Of course keep in mind that with irons and blankets aluminum foil can be used to transfer heat, while with a heat lamp it is used to reflect it. As far as certain parts absorbing heat more and warming the glue joint unevenly, I wouldn't worry about it. By the time the heat migrates from the surface to the glue joint it will have dissipated and evened out. |

|

| Author: | Michael McBroom [ Sun Feb 11, 2007 4:27 am ] |

| Post subject: | |

David, I like your heat lamp idea. Where would a person be able to find one that will work well for this application? Best, Michael |

|

| Author: | David Collins [ Sun Feb 11, 2007 6:40 am ] |

| Post subject: | |

You should find them at any hardware store or farm supply. I use the infrared flood-lamp style bulb (I forget the wattage, but there's usually only one style to choose from), and the ones with the red glass instead of clear are a little easier on the eyes. I still usually put on shades when heating though. Depending on the area that needs to be heated I will place the lamp anywhere from an inch or two from the surface to just about resting right on it. For a fingerboard it may help to have two, but I just move it along the length and heat it in sections. Heating an inch from the surface for 2 1/2 minutes +/- thirty seconds is usually plenty to soften PVA's. If I expect hide glue was used I will generously moisten the board and typically have to heat a little longer. Of course this varies widely, and if you try to start seperating and it doesn't feel right just stop and go back for another 30 seconds to a minute. Of course protectors for things like the headstock (or body if it's still attatched) can be made with cardboard, aluminum foil and metal tape from the HVAC section of you hardware store. |

|

| Author: | crazymanmichael [ Sun Feb 11, 2007 9:45 am ] |

| Post subject: | |

i've used clothes irons, heating blankets and a neat little heater i found in a junk shop to loosen fbs. i've not used a heat lamp. but all of these methods work with the frets in the board, just make sure you take the precautions mentioned above. i use spray glue to put alfoil on cardboard to mask off for protection. |

|

| Author: | Shawn [ Sun Feb 11, 2007 9:59 am ] |

| Post subject: | |

I have used all of the above with the exception of the hat lamp. It makes sense and given the precautions mentioned should work well. |

|

| Author: | Steve Saville [ Sun Feb 11, 2007 10:36 am ] |

| Post subject: | |

I put one in my oven at 175 F for about 30 minutes. That softened it up enough for me to drive chisel in the glue line and take it off. It was without frets and unfinished. |

|

| Author: | martinedwards [ Sun Feb 11, 2007 11:17 pm ] |

| Post subject: | |

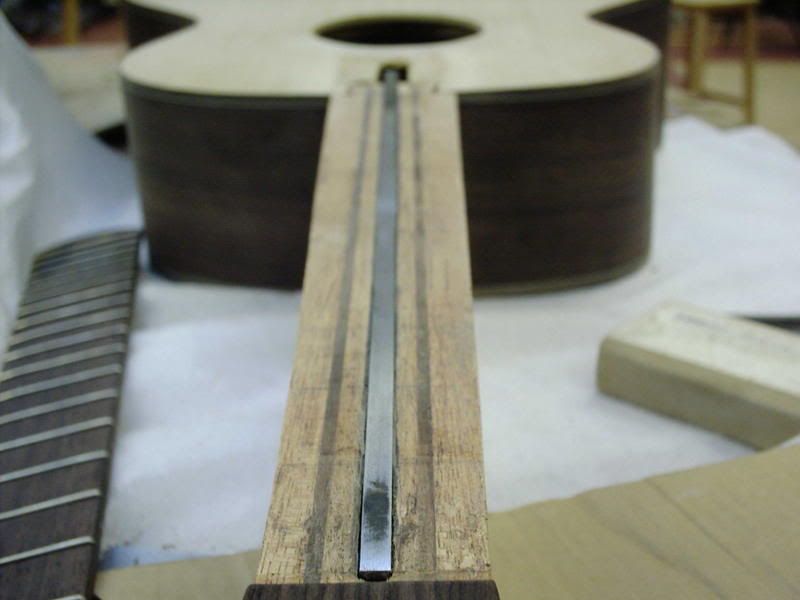

here's a thread I posted on the Jam session forum a month or so ago....... hope this is helpful. the guitar is a nearly finished jumbo that the truss rod snapped in before I managed to get the varnish on. The Iron is a $10 supermarket special set as hot as it'll go. Cardboard to protect the cedar.....

then a steel rule slipped in under the edge of the F/B

and worked along as the glue softened.

til after about half an hour (for once I took my time!!!).......

New rod put in.....

and fingerboard glued back on and clamped  [/QUOTE] [/QUOTE]

|

|

| Author: | MarkW [ Mon Feb 12, 2007 2:09 am ] |

| Post subject: | |

Michael, I've had good luck with both the clothes iron and heat lamp methods. I would also add that using a little kitchen timer with an alarm feature is a good idea. The digital ones are pretty cheap. |

|

| Author: | CarltonM [ Mon Feb 12, 2007 6:45 am ] |

| Post subject: | |

Martin, Thanks for the procedural. If a picture = 1K words, you just gave us 6,ooo helpful ones! |

|

| Page 1 of 1 | All times are UTC - 5 hours |

| Powered by phpBB® Forum Software © phpBB Group http://www.phpbb.com/ |

|