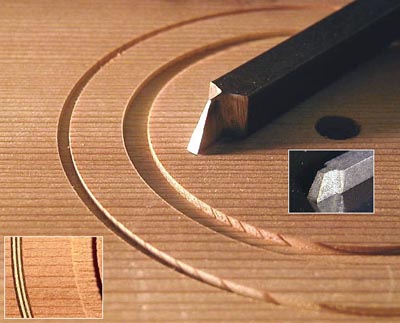

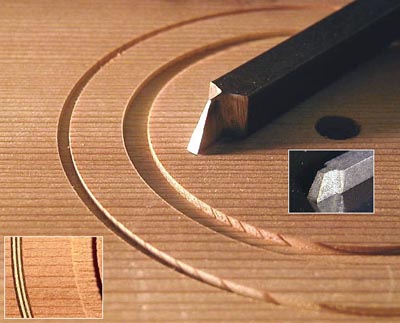

I'm not sure if we're talking the same type of cutter here, but here's what I do. The photo shows two different bits and how I ground them. At places (like MSC?) the bits are about a dollar each.

| Official Luthiers Forum! http://w-ww.luthiersforum.com/forum/ |

|

| Tip for those who use circle cutters. http://w-ww.luthiersforum.com/forum/viewtopic.php?f=10102&t=1152 |

Page 1 of 1 |

| Author: | Dave Rector [ Fri Feb 25, 2005 11:55 am ] |

| Post subject: | |

Here's a tip I just discovered for all those of you who use circle cutters to do rosettes and such. When I was at Frank Finnochio's class I noticed that he had a number of cutters for his circle cutter that had different thickness for the different purflings and inlays he uses. When I got home I went down to Woodcraft and sure enough they had the replacement cutters for around $8.00 apiece. Seemed a little high to me. I was looking through Grizzly's big catalog a few days ago in the reading room and found that they had tool steel bits for a metal lathe that had a little cobalt added for durability. They happened to be exactly the same size as the cutters I needed. And they were only $1.95 each. I reground and sharpened one up today and was very happy with the cut I was able to get with it. I ordered several of them on my last order, so I'm gonna grind them to the various thicknesses I need and I will be able to just swap a cutter and inlay the b/w/b lines or whatever.... Hope this is of some use to someone. |

|

| Author: | Dickey [ Fri Feb 25, 2005 12:26 pm ] |

| Post subject: | |

Describe how you resize them Dave. TIA |

|

| Author: | Dave Rector [ Fri Feb 25, 2005 1:18 pm ] |

| Post subject: | |

I just ground them down om=n my bench grinder (carefully, and dip them in water to keep them cool), then sharpened them up on the Tormek. I grind mine so there is a back angle and only th very front edge is doing the actual cutting. |

|

| Author: | John Mayes [ Fri Feb 25, 2005 4:21 pm ] |

| Post subject: | |

I do this with my ukes (they all have different soundhole sizes and rosette outside diameters. I just buy the $8 fly cutter from home depot or whatever and get the bits and grind them to what I need. I've also see guys take a spade bit and grind it down to cut a three ring rosette in one shot with a simple fly cutter and a spade bit really ground and modified. It worked really well. |

|

| Author: | Dickey [ Fri Feb 25, 2005 8:07 pm ] |

| Post subject: | |

Spade bits, man that's amazing John. and cool. |

|

| Author: | Dave Rector [ Fri Feb 25, 2005 11:12 pm ] |

| Post subject: | |

John, the nice thing is, for the price that you are paying for a new circle cutter - just to get the bit - I can buy 4 of these bits and grind them all to different profiles. The grinding only takes about 5 or 10 minutes since they are relatively small. You might even be able to use it as is, since it does come with a slight bevel already ground into it. |

|

| Author: | Pete Licis [ Mon Feb 28, 2005 4:40 am ] |

| Post subject: | |

I'm not sure if we're talking the same type of cutter here, but here's what I do. The photo shows two different bits and how I ground them. At places (like MSC?) the bits are about a dollar each.

|

|

| Author: | Dave Rector [ Mon Feb 28, 2005 6:02 am ] |

| Post subject: | |

Yeah Pete, that's the idea! Looks like you've found an even cheaper source than I did. Thanks for the info! |

|

| Author: | John Mayes [ Mon Feb 28, 2005 11:53 am ] |

| Post subject: | |

No I'm not using it just to get the bit. On my ukes there are 4 different soundhole sizes, and likewise 4 different rosette diameters. I use a separate one for each. I don't care about the money. I care about the time it takes to change it for each one. That way I just swap the cutter to match the model. Much less set-up time and time is money. |

|

| Author: | Dave Rector [ Mon Feb 28, 2005 12:09 pm ] |

| Post subject: | |

That makes sense. Thanks for the clarification. |

|

| Page 1 of 1 | All times are UTC - 5 hours |

| Powered by phpBB® Forum Software © phpBB Group http://www.phpbb.com/ |

|