Hello All,

I thought I would be smart, and take a brad point 1/4" drill bit. Drill in reverse through the back

of the 1/4" pre-drilled peg head hole, so as to create a small hole in the peg head veneer.

The object was to find the center of the hole in the veneer, so I could then drill through the veneer

side (Face) of the peg head to prep for the tuners. As you will see in the picture below, I pressed

a little to hard, when drilling in reverse. OK! I was pressing a lotta to hard! Another lesson learned.

Anyway, I guess its obvious what I need to do. Remove the veneer? However, I’m

always open for suggestions. Oh! I should also say, that Paul Bordeaux is making an inlay of

about 1.5"X1.5" for the peg head. This may end up being a perfect opportunity to use a veneer

that better suits the inlay. I had already installed the rosewood veneer before I called Paul.

Hope your listening Paul!

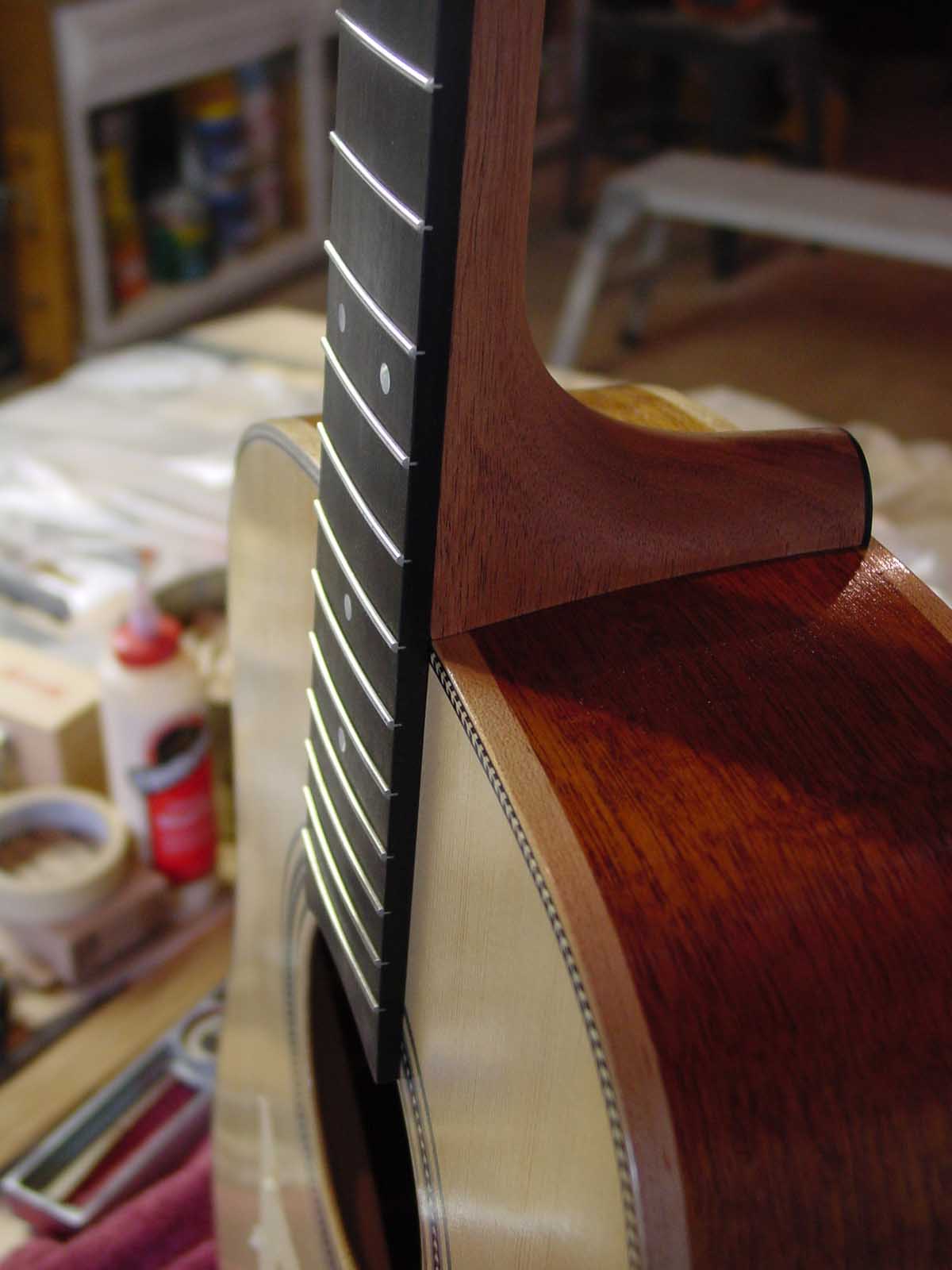

Since I was taking pictures, I thought I’d show everyone where I’m at right now. The body has

the fourth coat of true oil, the neck only one. The body has not been polished.

The LMI procedure called for 0000 steel wool. However, I didn’t like what it was doing to the finish.

It appeared to aggressive for me. So, I’ve decided on the alternative LMI method of using

the 6000, 8000, 12000 Micro-Mesh sand paper, which is on order. Sorry about the quality of the pics.

Peg Head Mishap!

The following shows that I've laid out for the bridge.

the neck is not permanently installed. After taking the pics,

I removed the neck, and sanded off the finish for both

the fretboard and the bridge.

Thanks for looking, Robert