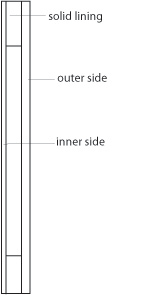

[QUOTE=Doug O] Hesh, the diagram below is from the thread on this

subject linked above. It seems that if you put a nomex core into this

assembly, where this detail is showing a void between the inner and outer

plies, you could potentially get a very rigid side, while solving the binding

problems you pointed out.

2007-01-10_155450_side-schematic.jpg"> 2007-01-10_155450_side-schematic.jpg">

Constructing back and sides using a "multiple ply" assembly provides

incredidble access to exotic tonewoods (veneers) that are largely

unavailable in solid wood. There is a veneer dealer 30 minutes from my

house that stocks tone wood species in quality of figure that's

simply amazing. Not to mention flitch cut Brazilian RW.

It seems that one of the largest hurdles is overcoming the "plywood"

stigma. But isn't a spruce double-top with a nomex core on a $12,000

classical just a plywood soundboard with a different name and a bit of

high tech mojo? [/QUOTE]

This is a good idea, but I think Nomex is the wrong product for the core. I

spoke with Randy Reynolds a couple years ago about this because he

knew I had done a lot of experimenting "composite tonewood". He was

going to laminate his sides and wanted to find a light core material that

would be suitable. He could not find the product that I suggested which is

called Airex R63. So he got some blue, closed celled foam from the home

center and sliced it into thin 2 mm slices on the bandsaw. I am not sure

how that turned out but is is probably a nice light, stuff layup. The skins

could be almost as thin as possible and still retain the stiffness required.

The stiffness comes from the distance that the skins are spaced apart and

their tensile strength.

After saying all this I would highly suggest sticking to good old wood and

don't even get into this stuff.

|