John, The way I do my wood rosettes is really simple and it works just as well for installing segmented rosettes.

I thin the material to around .070 then mark it with a compass or a template. Then I just cut it out with a bandsaw, and spindle sand till the line is gone and it fits in the channel. (It doesn't have to be tight it just has to be close) Sand this level. Then cut two more passes for the inside and outside purfling lines.

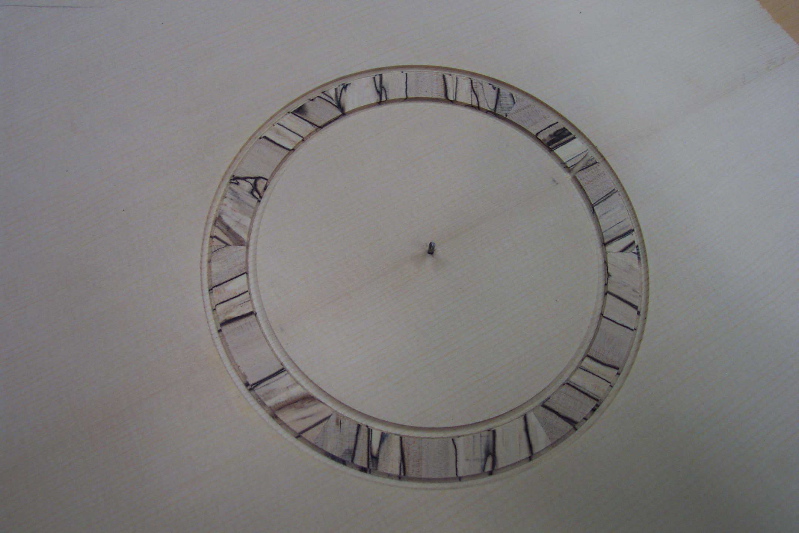

Here you can see the two passes for the purf have cut a little of the rosette and a little of the top to cover the sloppy fit we did putting in the wooden rosette sections.

I hope this makes sense, It's low tech, it's quick and easy, and it's always nice and tight.

Here is it when it's done...

Long

, but my cutter did not throw it, think it has a safety or something. I have a table top press and it does not wobble too much. I am having a hard time just keeping the press table flat and level.

, but my cutter did not throw it, think it has a safety or something. I have a table top press and it does not wobble too much. I am having a hard time just keeping the press table flat and level.