I have used John Halls version of the "Ribbecke" binding machine and depending on your bit and bearing set you will need to cut the purfling ledge first. This rig works great as does the Williams/Fleshman (sp) set up.

My issue with the "Ribbecke" rig is that it will not allow clearance of the neck block area when cutting some cutaways. The Williams/Fleshman does not have this issue. but the only way to get one now is to build it. but it is not hard.

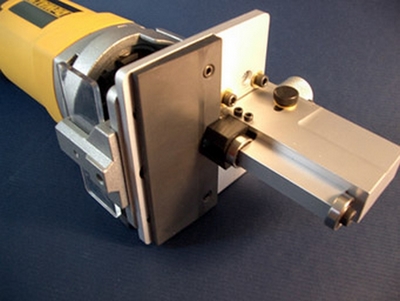

Now days I use neither. instead I use this hand held system from luthierstools.com. I really like it because it uses 2 bearing. one at the lower edge and one near the cutter to maintain a good square cut. With it you can cut the binding ledge first if you wish.

I find it much more versatile than the Ribbecke rig that LMI sells