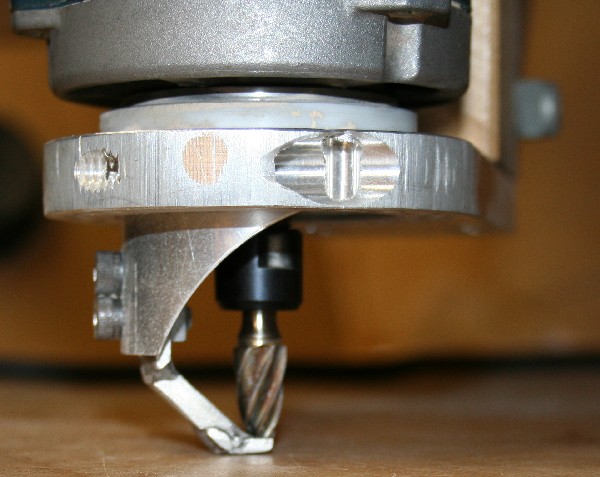

Hey, does anybody know what kind of bit this is? I think it is a metal working bit, but I am not very versed in such things.

I would like to find something similar that has a 1/4" shank and can be mounted in a lam trimmer.

Thanks.

| Official Luthiers Forum! http://w-ww.luthiersforum.com/forum/ |

|

| What is this bit, and where can I get one http://w-ww.luthiersforum.com/forum/viewtopic.php?f=10102&t=12157 |

Page 1 of 2 |

| Author: | Brock Poling [ Wed May 23, 2007 12:45 pm ] |

| Post subject: | |

Hey, does anybody know what kind of bit this is? I think it is a metal working bit, but I am not very versed in such things. I would like to find something similar that has a 1/4" shank and can be mounted in a lam trimmer. Thanks.

|

|

| Author: | Doug O [ Wed May 23, 2007 1:31 pm ] |

| Post subject: | |

It looks like a tapered end mill intended for use in metal. End mills come just about every possible configuration from degree of taper, number, length, hand and twist of flutes, coatings, HSS, carbide, diameter at tip, etc, etc. Any good machine tool supplier should be able to fix you up. I get that kind of thing from a local dealer (American Equipment & Tool in Tacoma, WA) because I don't like buying it on line due to the fact that I don't know enough about what I'm asking for. |

|

| Author: | Pwoolson [ Wed May 23, 2007 1:46 pm ] |

| Post subject: | |

Brock, it is indeed an end mill which is a metal cutting bit. I'm curious why you want one. Using it on wood will likely have yucky results. Because there are so many flutes, it won't have time to cool and will result in lots of burning in your cut. |

|

| Author: | Andy Zimmerman [ Wed May 23, 2007 1:59 pm ] |

| Post subject: | |

Brock That set up looks familiar!!!!

|

|

| Author: | Pwoolson [ Wed May 23, 2007 2:04 pm ] |

| Post subject: | |

What's it for? |

|

| Author: | L. Presnall [ Wed May 23, 2007 2:15 pm ] |

| Post subject: | |

Andy, don't tell me you use that thing in the O.R.!

|

|

| Author: | Steve Saville [ Wed May 23, 2007 2:16 pm ] |

| Post subject: | |

Have you asked Him? Ray might be able to help you. |

|

| Author: | Bob Garrish [ Wed May 23, 2007 2:22 pm ] |

| Post subject: | |

It's certainly not an end mill. It's a carbide burr, like highdrawlicks suggested. They're made for use freehand in wood and plastic, or in softer metals for the small ones (we're talking 1/8" and smaller). |

|

| Author: | Bob Garrish [ Wed May 23, 2007 2:29 pm ] |

| Post subject: | |

Oops, I just looked at the pic again and I was off on the last bit. The burr in the picture is an open-flute burr, which are the kind that can be used in soft metals. |

|

| Author: | Steve Saville [ Wed May 23, 2007 2:35 pm ] |

| Post subject: | |

I think I found it. McMaster Carr Carbide Burr. Item #43035A65 has a 1/4 shank and a 1/4" tall cutter $33.29.

|

|

| Author: | PaulB [ Wed May 23, 2007 3:52 pm ] |

| Post subject: | |

Also similar burrs on page 93 of the latest Lee Valley catalog. |

|

| Author: | Brock Poling [ Wed May 23, 2007 3:55 pm ] |

| Post subject: | |

[QUOTE=azimmer1] Brock That set up looks familiar!!!!             [/QUOTE] [/QUOTE]

Yeah, I thought you might recognize that.

|

|

| Author: | Brock Poling [ Wed May 23, 2007 3:56 pm ] |

| Post subject: | |

[QUOTE=SteveS] Have you asked Him? Ray might be able to help you.[/QUOTE] I try not to bug him. |

|

| Author: | Brock Poling [ Wed May 23, 2007 3:59 pm ] |

| Post subject: | |

[QUOTE=Pwoolson] What's it for?[/QUOTE] It is for taking meat out of braces. You can use it after the braces are glued into the plates. |

|

| Author: | Brock Poling [ Wed May 23, 2007 4:00 pm ] |

| Post subject: | |

[QUOTE=SteveS] I think I found it. McMaster Carr Carbide Burr. Item #43035A65 has a 1/4 shank and a 1/4" tall cutter $33.29.  [/QUOTE] [/QUOTE]

Awesome...Thanks!! |

|

| Author: | Rod True [ Wed May 23, 2007 4:31 pm ] |

| Post subject: | |

ES uses one of those I guess hey guys (do you guys get to do any of your own stuff after taking his course? Just kidding {sort of}). Be careful you don't slip and cut something you don't want to. That thing will be moving a lot faster than a chisel or instrument makers plane. I can see from the picture that it's got a guide at the bottom, assumed that the guide rides along the plate and the bottom of the brace, making a inverse parabola shape to either side of the brace. This will be a nice quick way to remove material.

|

|

| Author: | Brock Poling [ Wed May 23, 2007 10:18 pm ] |

| Post subject: | |

[QUOTE=Rod True] ES uses one of those I guess hey guys (do you guys get to do any of your own stuff after taking his course? Just kidding {sort of}).[/quote] Let's not go down that road again, ok?

But you are right, there isn't much mystery to it, it is a nice predictable way to remove material from the side of a brace. |

|

| Author: | Pwoolson [ Wed May 23, 2007 11:06 pm ] |

| Post subject: | |

[QUOTE=Bob Garrish] It's certainly not an end mill. It's a carbide burr, like highdrawlicks suggested. They're made for use freehand in wood and plastic, or in softer metals for the small ones (we're talking 1/8" and smaller).[/QUOTE] I stand corrected. Hesh, me to. Without a base (which would get in the way between braces) I don't understand how you would get an accurate shape with this tool. |

|

| Author: | crazymanmichael [ Thu May 24, 2007 12:12 am ] |

| Post subject: | |

the little foot indexes off the plate and the base of the brace. the bellied shape of the bit removes a concave section of the brace whilst tapering it toward the top. the foot of necessity has to be small due to the curvature of the plate i think it definitely would not be a one handed operation!! makes me wonder whether the williams binding jig, which keeps the trimmer in a vertical attitude, could be used to take some of the risk out of the operation. i've known of folks who use the carbide burrs in a die grinder to rough carve necks. removes material very rapidly indeed. |

|

| Author: | JJ Donohue [ Thu May 24, 2007 1:00 am ] |

| Post subject: | |

IMO...this tool is an accident waiting to happen...both to wood and flesh. I can think of much safer ways to accomplish the same mission. |

|

| Author: | JJ Donohue [ Thu May 24, 2007 1:03 am ] |

| Post subject: | |

EDIT (sigh) I can see tearout, kickback and blood in someone's future! I hope I'm wrong but be very careful with this one! |

|

| Author: | Brock Poling [ Thu May 24, 2007 2:23 am ] |

| Post subject: | |

It will work fine I have seen it in action. It is held in a verticle alignment. I will probably build a flieshman style holder for it. I may also out a router speed controller on it. It is just a nice way to do a task repeatably and reasonably quickly Thanks for the help with the bit. BYW, this is my first post to the forum from my blackberry.

|

|

| Author: | crazymanmichael [ Thu May 24, 2007 2:41 am ] |

| Post subject: | |

jj, having used the bits in a die grinder i don't share your grievous safety concerns, given the normal sort of safety provisos applying to the use of such power tools. granted, a router bit with a similar profile would be better due to its better chip removal, etc. but a lot of folks have used them in wood carving, luthiery, etc., and i've not heard of any unusual accident statistics related to their usage.. however i do see where an instant of inattention or ineptitude could irrepairable damage a brace, and perhaps the top as well. hence my suggestion above regarding the use of the binding jig as a possible safe alternative to freehand use. a priori, i can't see any reason it wouldn't work. a riser platform would be required to get the plate up to a suitable working height, but it seems to me that the two dimensional free movement of the trimmer in the binding jig would suit this application very well whilst entailing only minimal time tradeoff. |

|

| Page 1 of 2 | All times are UTC - 5 hours |

| Powered by phpBB® Forum Software © phpBB Group http://www.phpbb.com/ |

|