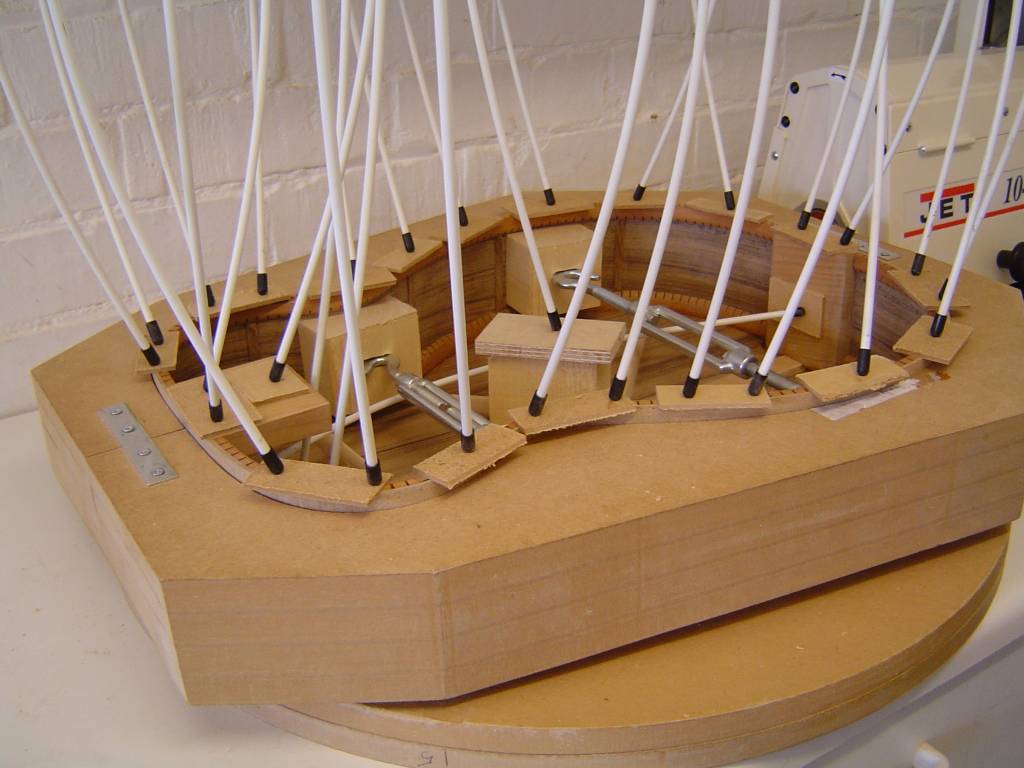

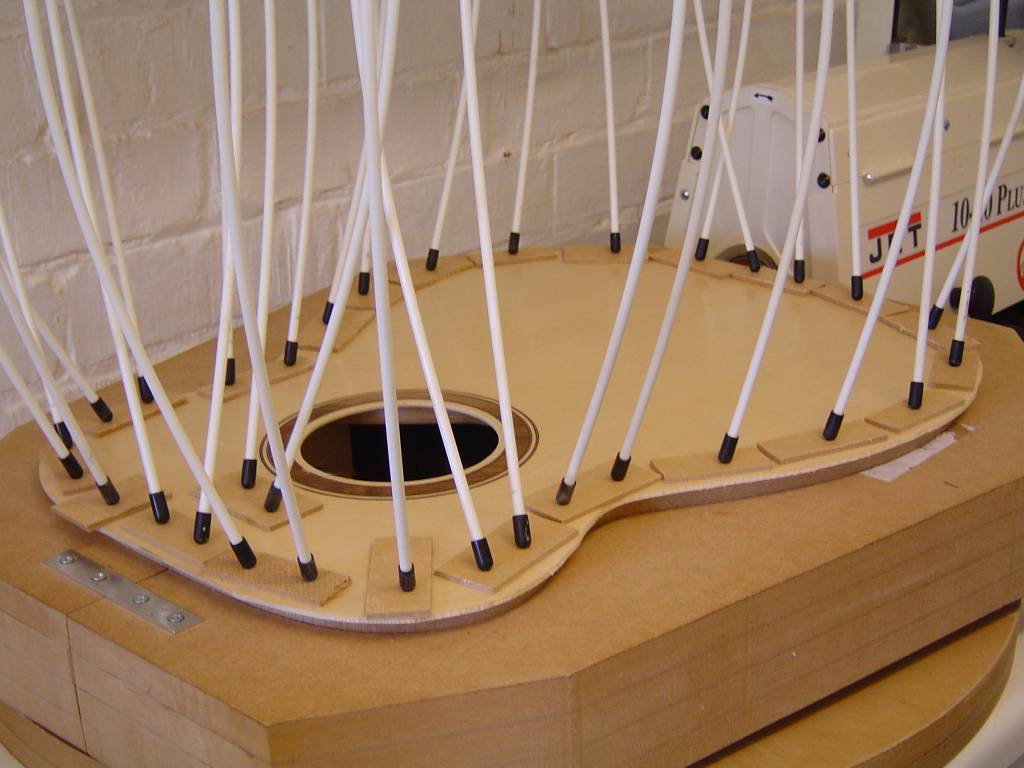

As threatened, here's a few more pics of the Tasmanian Tiger Myrtle SJ. First is a shot of the bracing pattern. The lighting is such that you can get a feel for the contours:

Next, gluing on the top...

Routing for the tail wedge:

Gluing in tail inlay w/ band clamps:

Wedge installed-- it is also Tiger Myrtle, as will be the bindings and back strap:

Thanks for looking, and thanks again to Tim Spittle for such a fine material to work with.

Steve

. Any tips on working with the Taz.

. Any tips on working with the Taz.

Lets help out where we can huh ?

Lets help out where we can huh ?