Hi all,

As I was mentioning in the other thread, here is a small tutorial on making an armrest or ribrest in a guitar, as I now do it. The original inspiration for these was of course Grit Laskin, and in an early Guitarmaker which I have, he authored a short description of how he does it. There was only a drawing of the rest's cross section, which I have also redrawn for the way I do them at the end - beyond that simple drawing, I had to figure it out on my own. So here goes ....

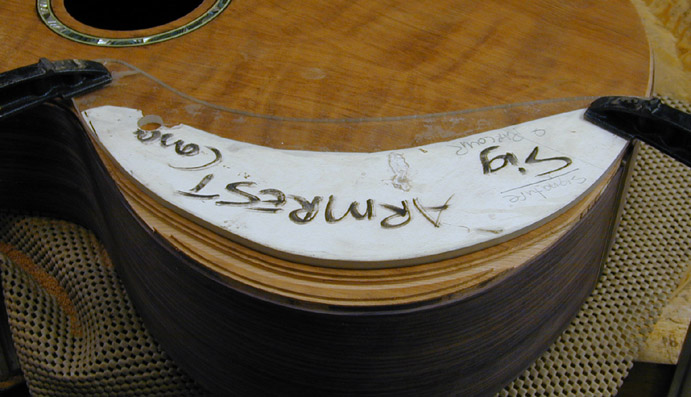

This is an armrest being installed into a EI rw and culry redwood top Karol Signature style - I have templates for the various lower bout shapes which correspond to the armrest shapes I make. I will assume that you have chosen a shape and installed the actual block into the gutiar, and the box is now closed and ready to be bound. For those unfamiliar with putting the block in, check Tracy's Luthier Supply website, he has a page there with an older tutorial I did o the MIMF, and it shows the internals of the block - I didnt take pix of this one (sorry).

So, the first thing to be done once the box is closed, is to route all the top binding and purfling channels - this will usually expose the ends of the internal rest block, so you will know where to place you template. If not, you can always reach inside and check by hand where the ends are (I also ALWAYS make a paper tracing of the block before I glue it in, then you know exactly what he shape is) The template is 1/4 plexi, and has been curved to the shape of the binding/purfling ledge of the rest (it could be either an armrest or ribrst, the procedure is the same), which I have sitting about 1/4 inch in from the inside edge of the internal block - use the template to give you the rough dimensions of the block, adding in the gluing surfaces - you obviously dont want to route thru the top !!!

So, place your template in the correct location, you can see the ledges for the top are already routed ..

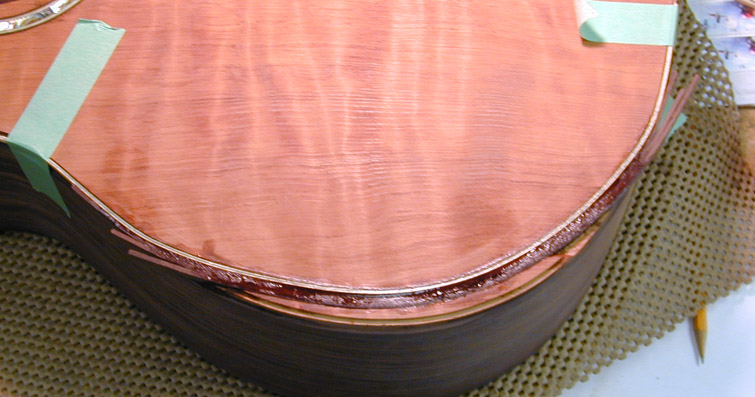

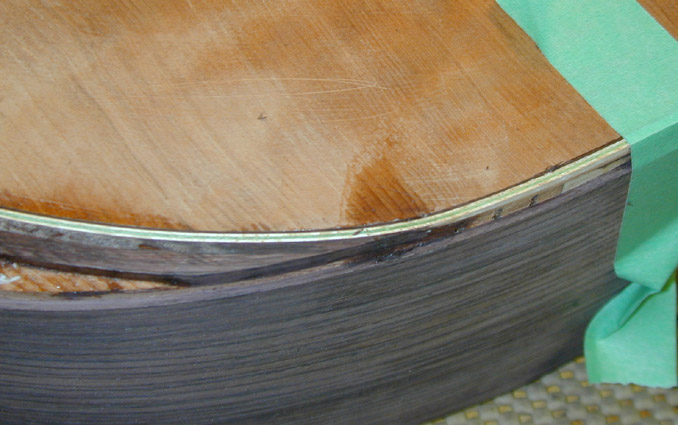

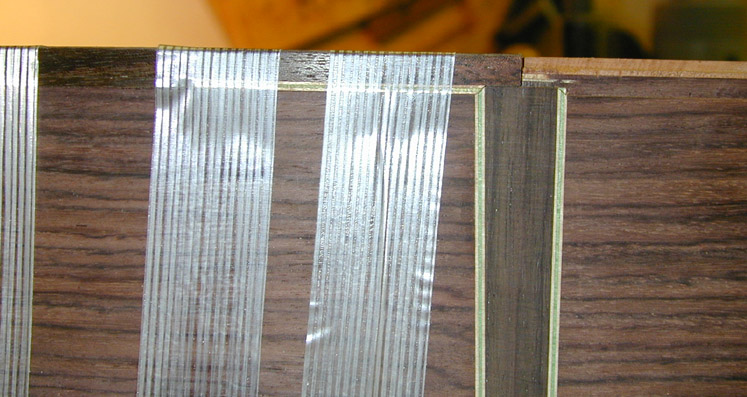

Once you have it clamped in place, you are ready to route the armrest binding and purf ledges - I use a lam trimmer, and template guides to give me the offsets I need, depending on the binding/purfling scheme. You may need to route the ledges best you can, and then trim up the purf ledge narrower with a chisel if required. This scheme was pretty wide, blk/maple/green/maple, then EI rw binding, so it worked out pretty good. I also like to bind in the same material as the sides, especially if the rest is not being blacked out (some will veneer the rest to match the binding, I have yet to do that, but that is what Ryan does). So, the purf ledge is the same as the rest of the top purf ledge in depth, the binding can be shallower than the top binding ledge, but still must go thru the top into the rest block - you want the armrest binding to transition neatly into the block, and not have a sliver of topwood showing thru, especially if the rest will be finished natural, as this one is, its a piece of redwood. You can see the grain lines of the rest piece are different in pix 2 and 3 here, from that of the top, showing how I have routed deep enough.

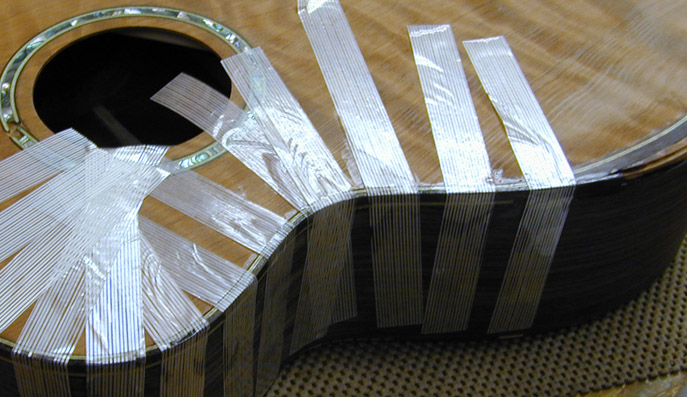

Now you are ready to begin binding ... I used to have sharper corners at the ends of the rest, and thus the required mitres - I modded the template so that the ends are now rounded, and the top half of the purf can be one piece - no mitres required, and a smooth look. The armrest binding is done in three pieces usually to get the width, each typical binding width, pipe bent to fit the channel - route the channel for the binding slightly wider than its depth - if you dont, you will have a tough time keeping the transition line even, and still have some binding left on the top surface. So fit the purf and binding in, it needs to fit SNUG ... you may need to scrape a piece thinner to make it all fit dry, then CA it all in.

Now the binding ends need to be trimmed off - but you mustnt touch the purfling - I have a dedicated lam trimmer set up for only binding ledge depth, so I use this to trim the excess off, laeving a smooth binding ledge again, just like the armrest wasnt even there ...

You are almost home free ... you now need to fit the remainder of the top binding in place. Since I dont bind or use any side purfling in the rest area, I chop the binding, and then stop the side purf on that binding right where the rest starts or ends. There will be a gap the height of the side purf once the purf is removed, and this will be filled with a fillet of binding wood, salvaged from the binding cutoff that is also conveniantly bent to shape .... hopefully the pic will help the explanation

Fit and glue these up, tape in place, and CA ...

Now the same is done at the tail block, and if required, its also mitred into the tailwedge as this one is ...

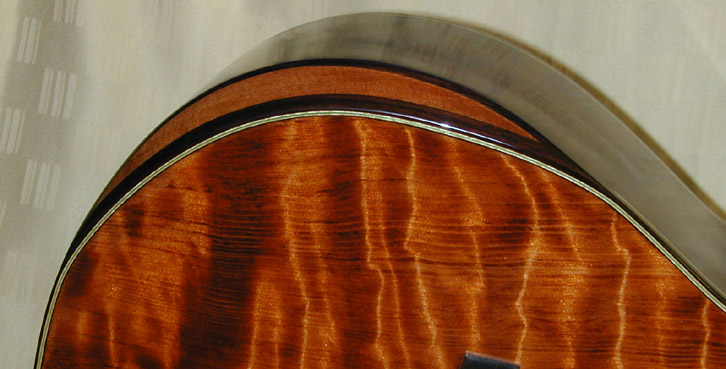

Now the binding of the rest is done, and you can carve the rest to shape. I use a block planne, rasp and sanding blocks to bring it to its final shape. Watch your angle, keep the rest about 45 degrees to the top, and once you have a smooth transition line from the rest block to the rest binding, and the corners look neat, you are DONE

Carry on and finish up the rest of the binding, and then finish ... hopefully it looks like this ....

Almost forgot .. here is my armrest in cross section.