Hi John,

I'm a relative newbie here, actually just finished my first build and am in the stringing up/tweaking stage. I don't claim to have a wealth of experience, but this worked well for me!

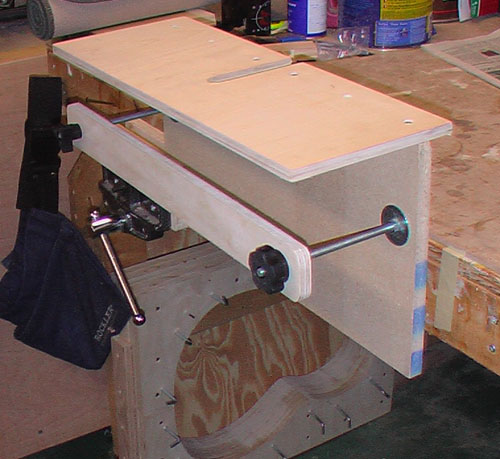

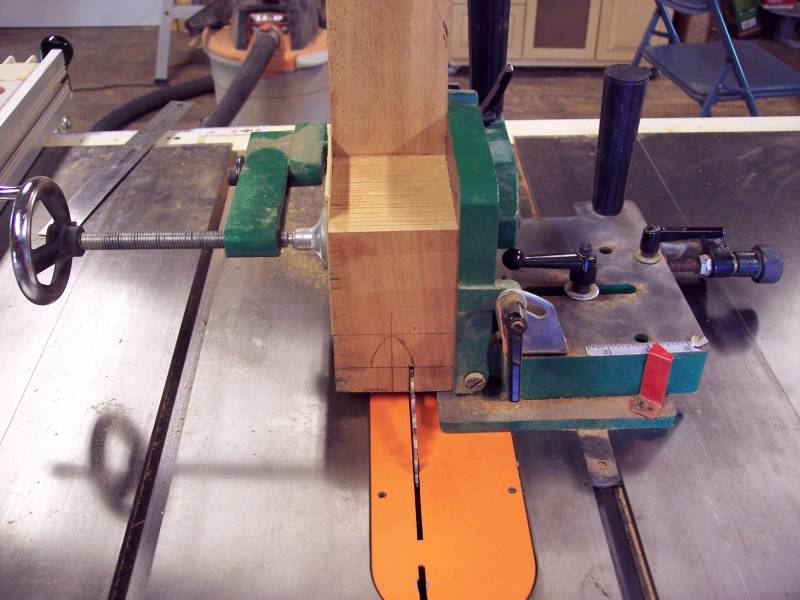

Attached (hopefully) is a pic of the jig I made for routing my neck joint. The entire top of the jig is removeable, held in place with dowel pins. With the template off, I clamp the neck blank in vertically to the long piece of plywood in the center (fretboard area facing OUT), which is angled 91 degrees to the top of the jig to allow for a slight back-angle when mated to the mortise. I just flush-cut this with the router, then add the template and rout the U-shaped tenon.

I have a similar jig for routing the mortise, the closed body clamps underneath the jig in the same way and the matching U-shape is the actual template on top. Hope this makes sense! if not, holler and I'll snap some pix of the body jig as well.

Cheers!

Jon