Hello All,

Well, let me first say, that I apologize, for ever starting the topic several weeks ago, “Is humidity really an issue”.

They say “experience is the best teacher”, and I got a big dose of it lately!

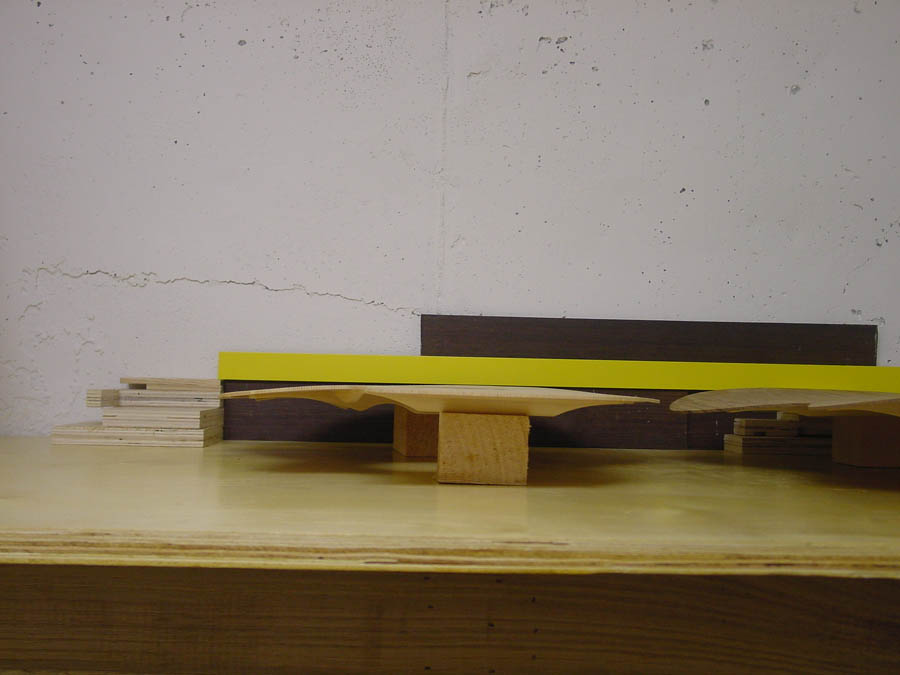

Recently I started a topic “Planning my next build!” which I got some good advise on where to go

with wood choices. JJ Donohue brought up a point that got me thinking, so, I posted a few pics

of the top & back set in question with edge views. That’s when the lesson began! It didn’t take

long for Don Williams, and Hesh to realize what had happened to the top & back! Yep! You guessed it!

TOO MUCH HUMIDITY!

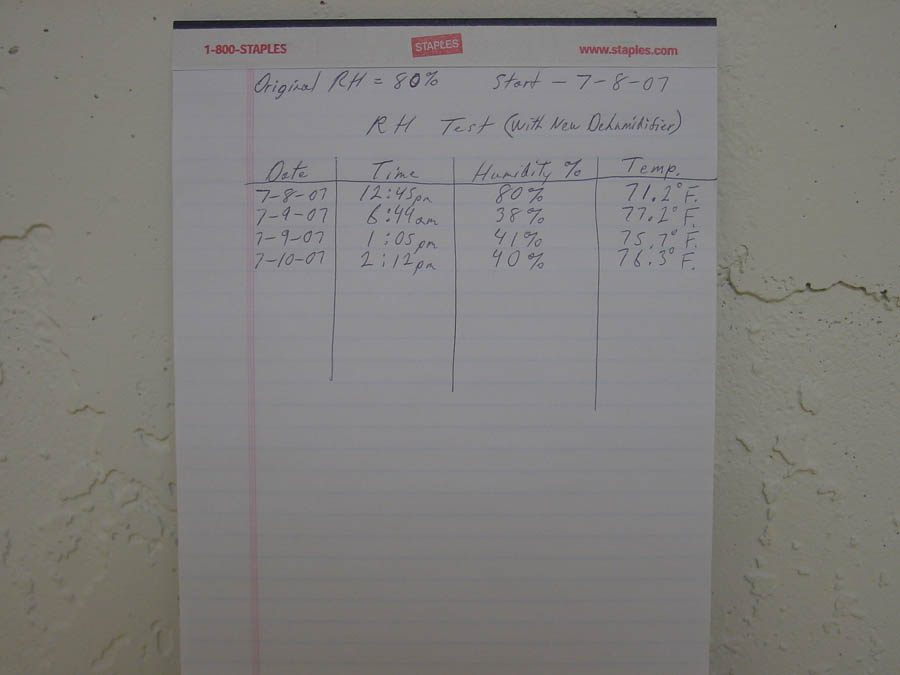

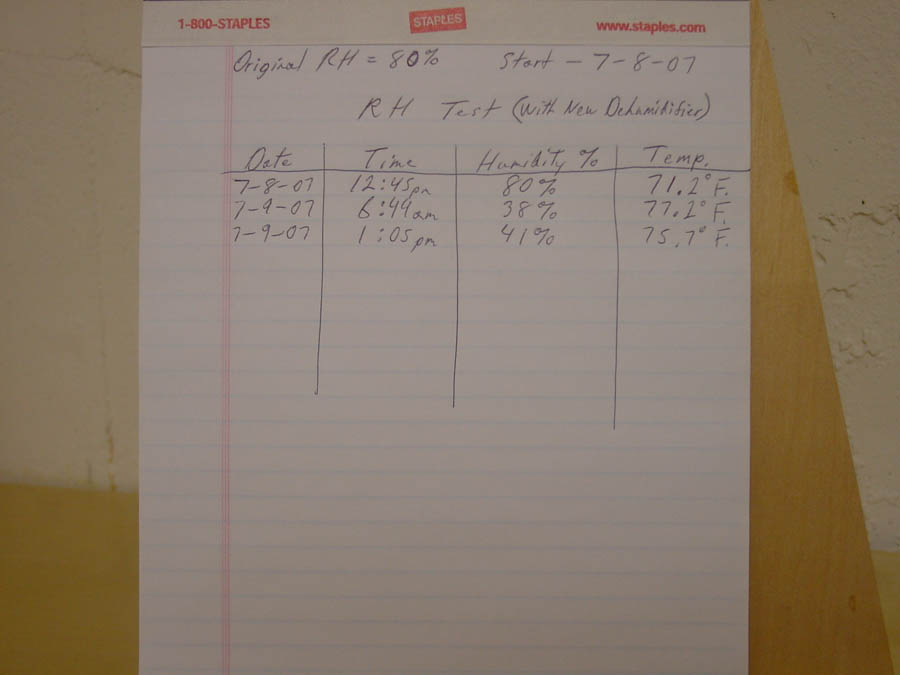

So, at the request of one the OLF tutorial masters “Hesh” and, after buying a new de-humidifier.

I’m recording the process of getting my shop to an acceptable RH.

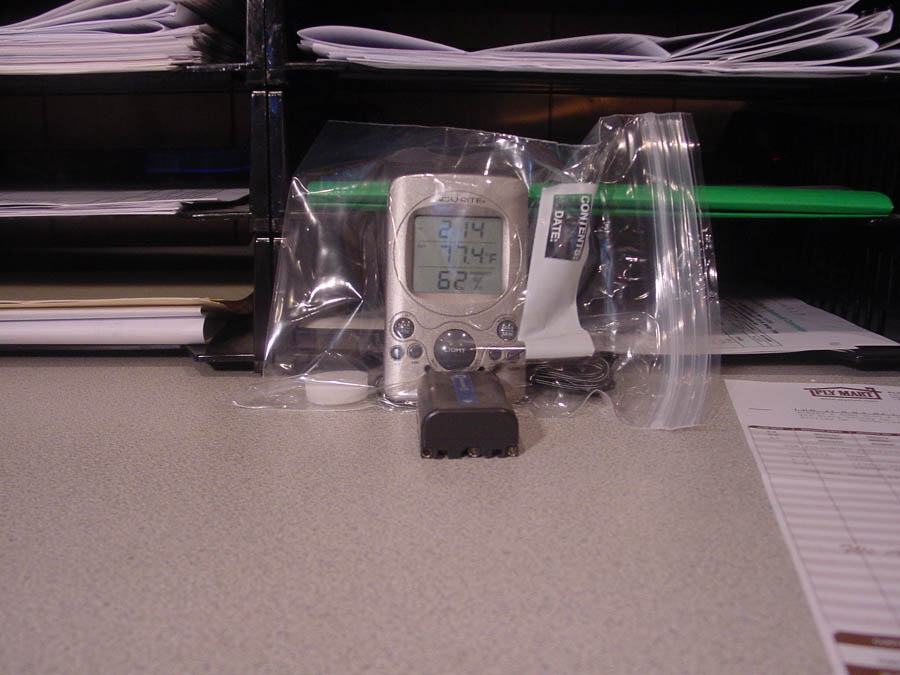

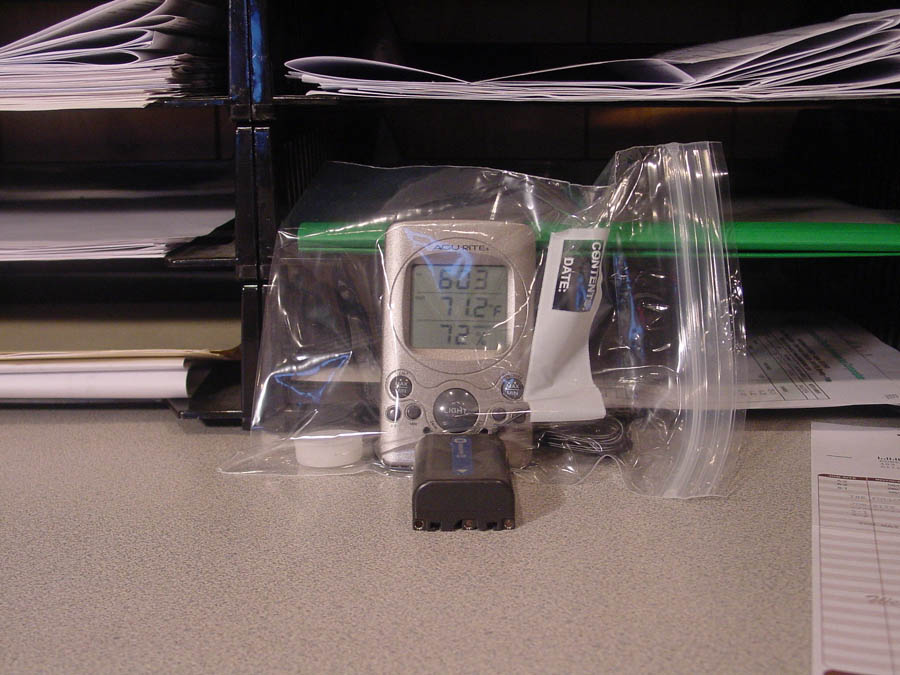

Starting at 80% humidity, and though only just over 24 hrs. I thought you might want to see what

I’ve got so far. It’s amazing to me that in just 24 hrs. there have been very noticeable changes.

I lost the first pic of the new de-humidifier when I first turned it on, but, it was set to 45%RH

and the actual humidity was reading 70%RH on the de-humidifier it self. This at first was a little

confusing, because my other humidity meter that I keep on the bench was reading 80%. Things

did seem to even out after 24 hrs. had past. And, I suppose that will continue for several more days.

The first pic is a log I started. The rest are in chronological order with titles corresponding to the log.

The Log

Humidity Meter

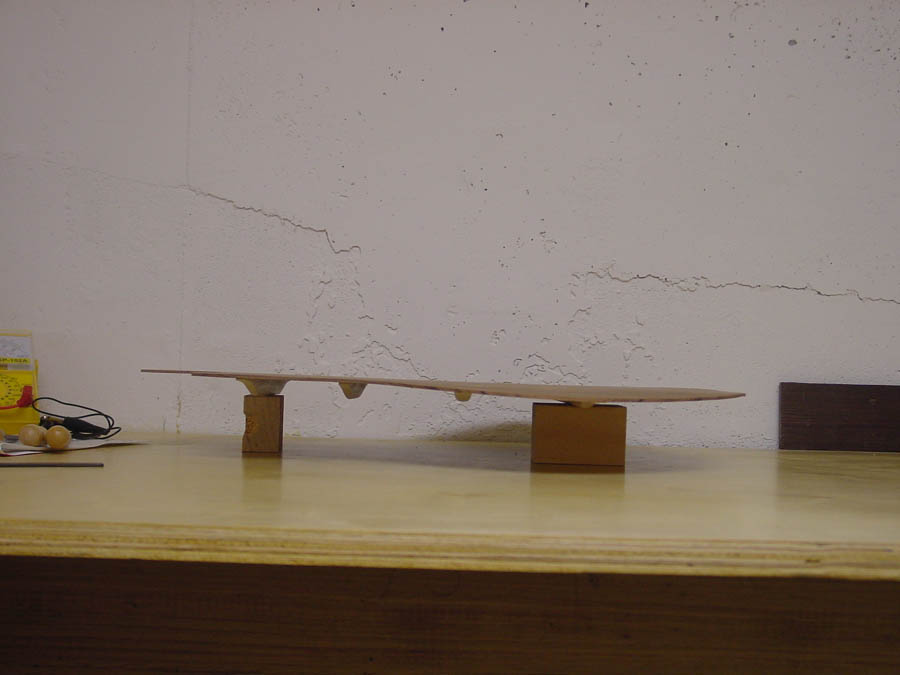

Top at 80 RH

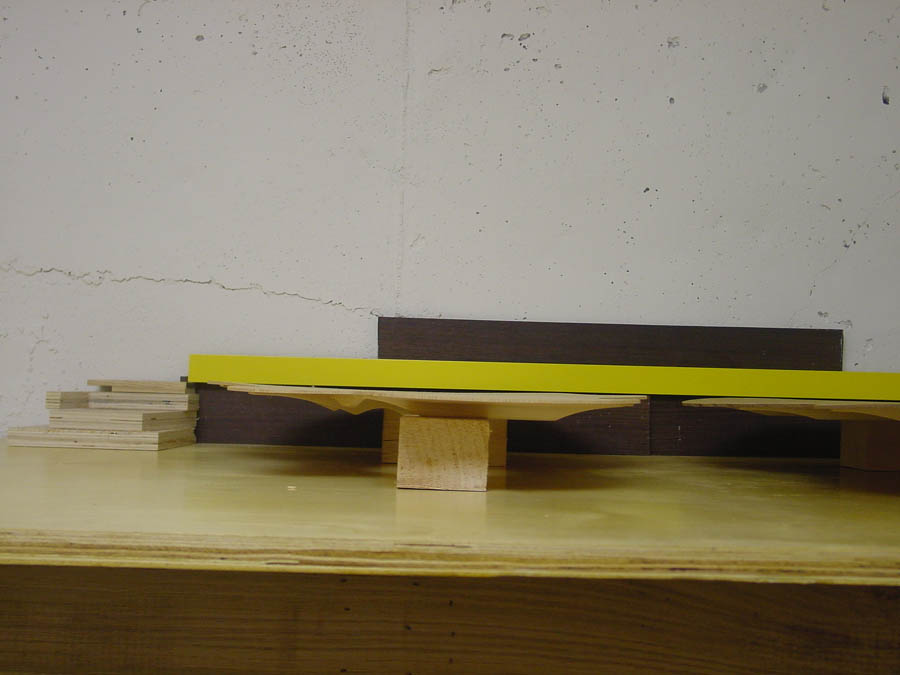

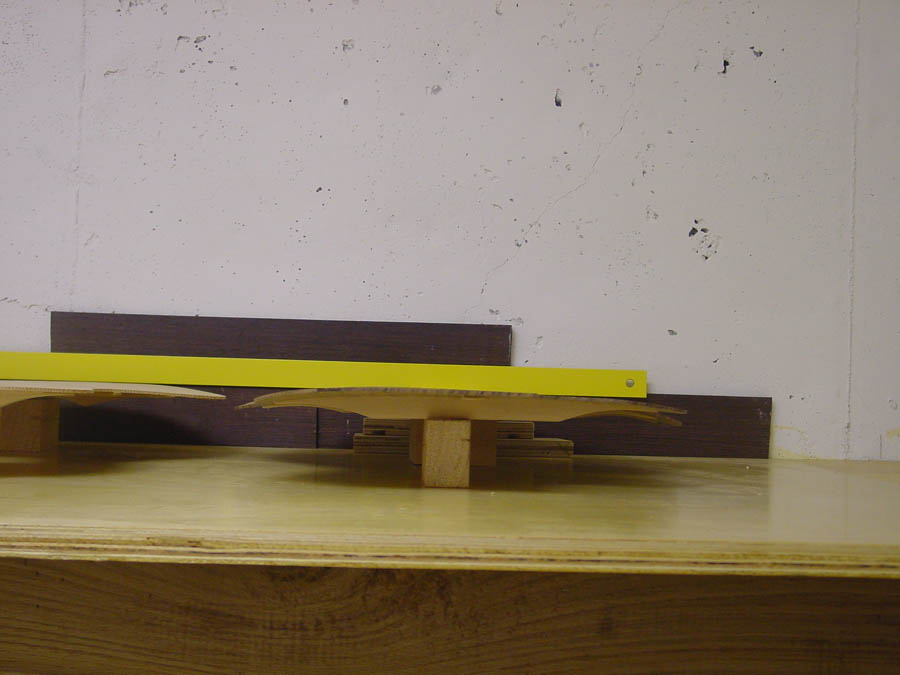

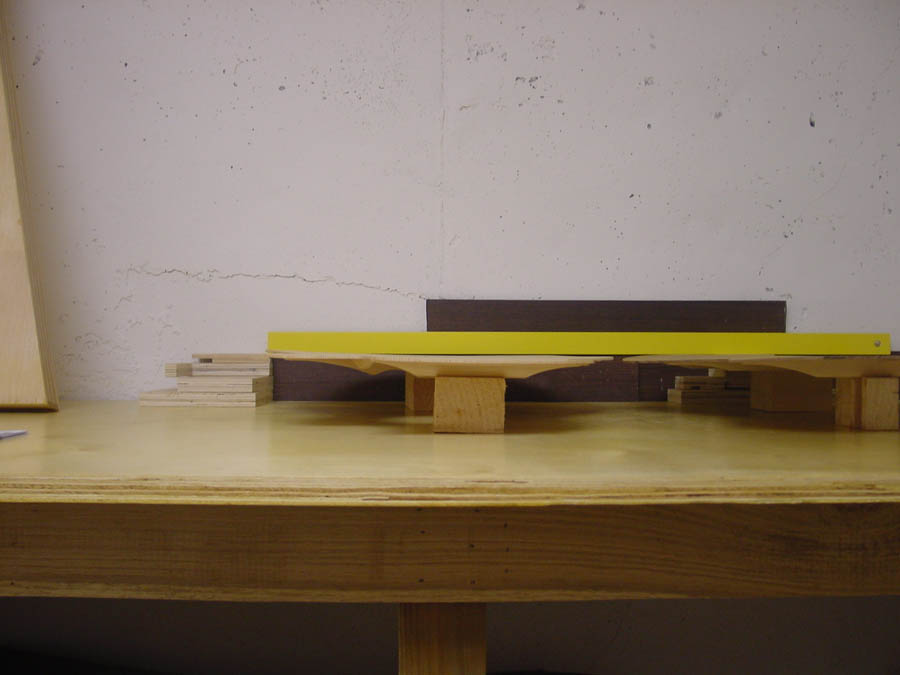

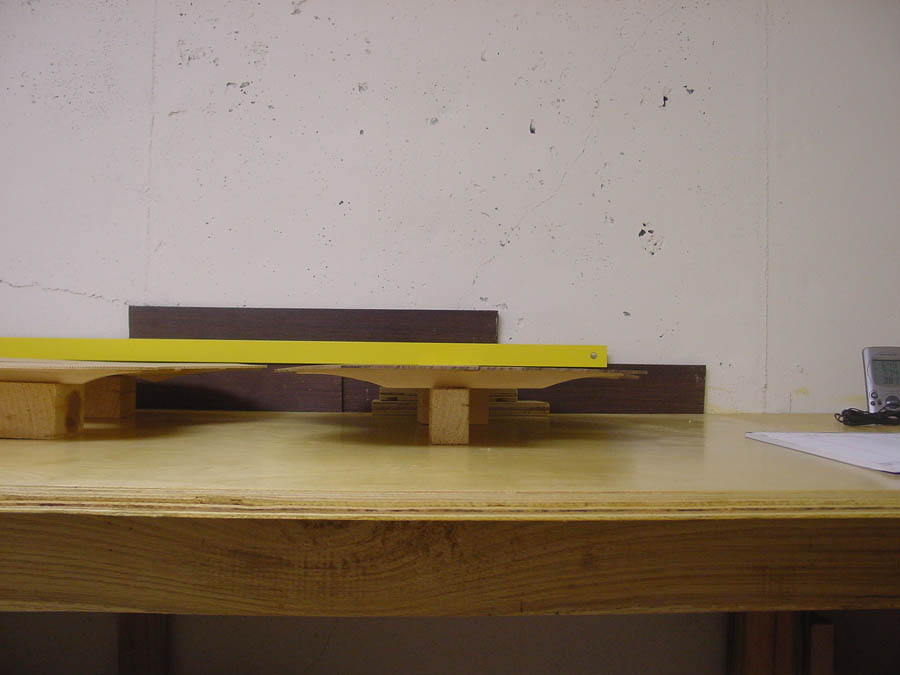

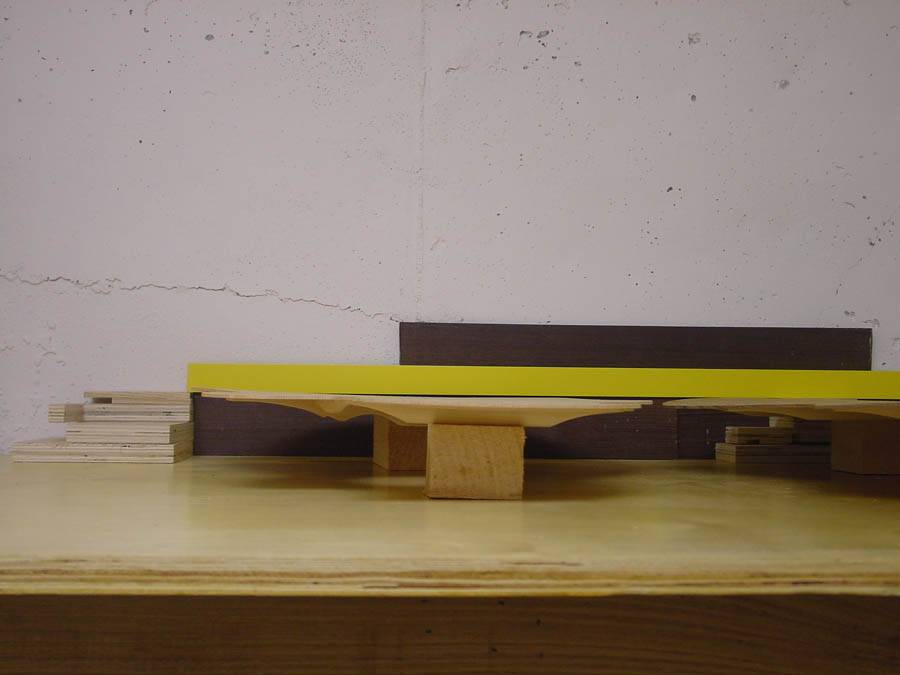

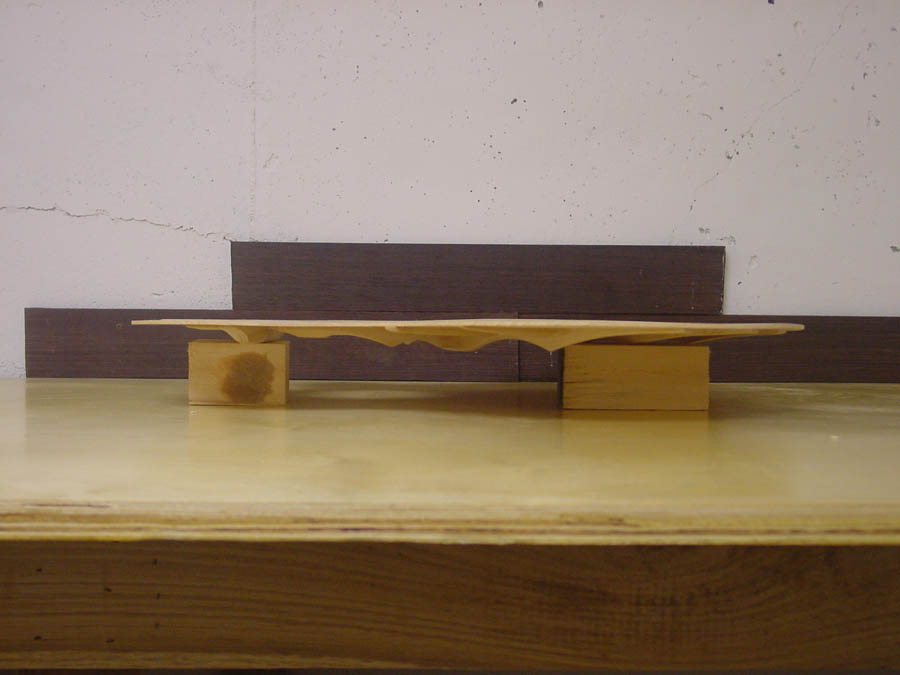

Top side view at 80 RH

Back at 80 RH

Back side view at 80 RH

Humidity Meter

Top at 38 RH

Back at 38 RH

Humidity Meter

New dehumidifier

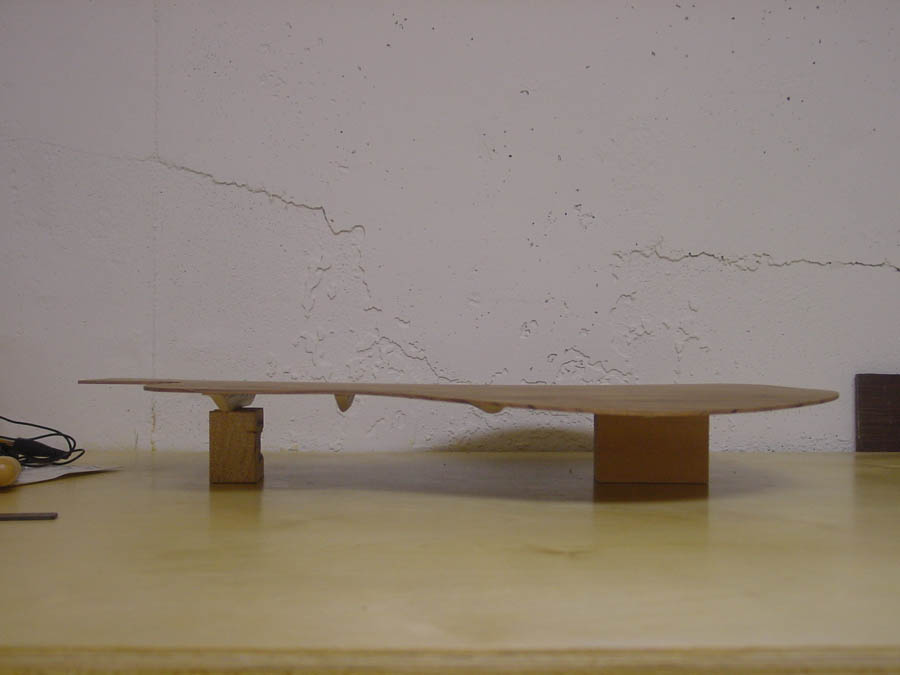

Top at 40 RH

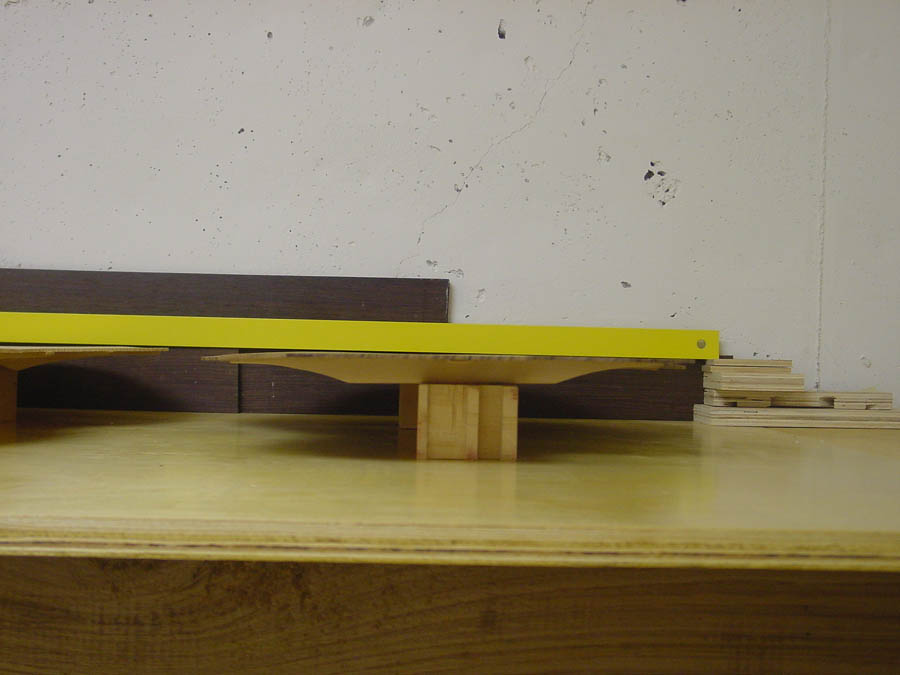

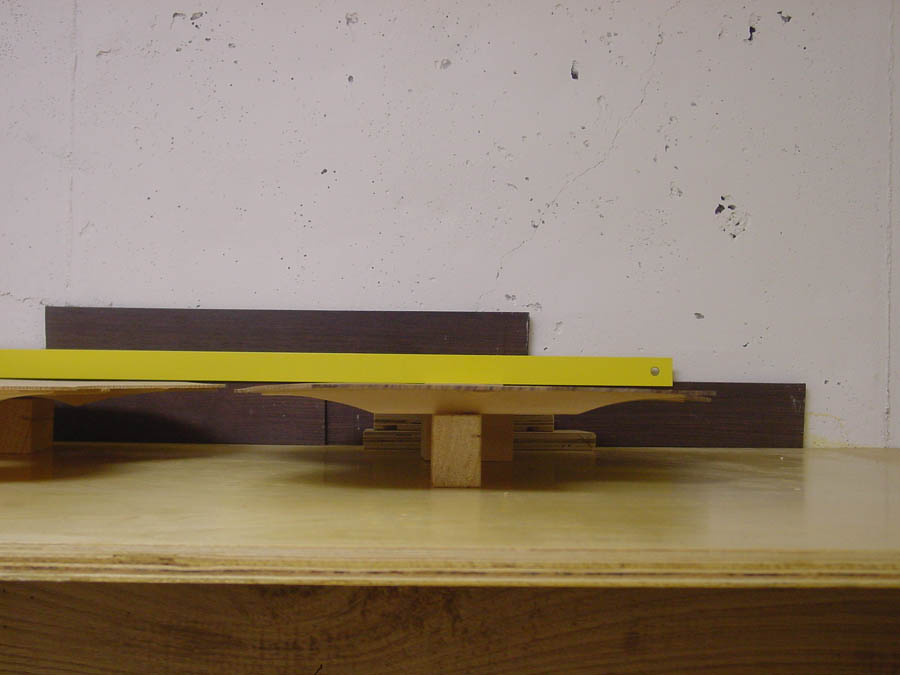

Top side view at 40 RH

Back at 40 RH

Back side view at 40 RH

If you got'em ask'em!

Robert