Hi, James asked if i would share how i carve my volutes...

first a disclaimer: my methods are risky, use caution if you try this at home.

first I get my blank roughed out on the bandsaw.

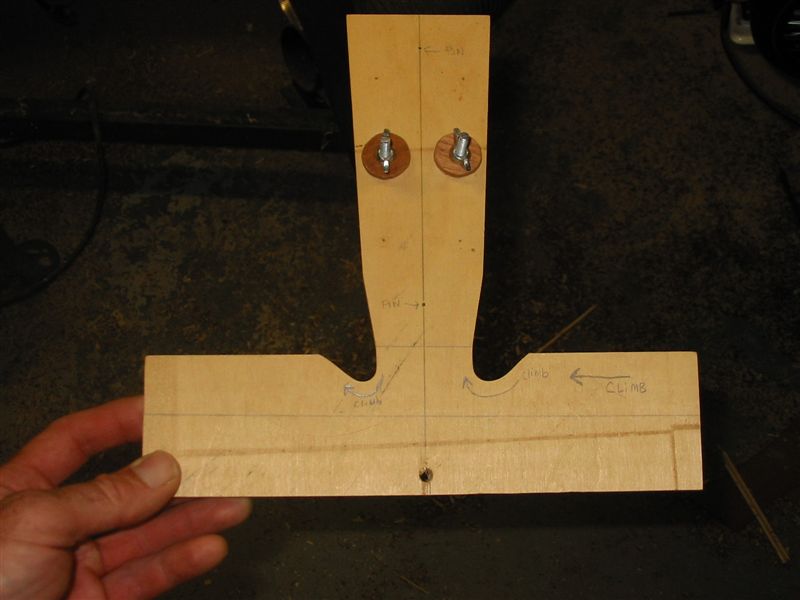

in this shot you can see the simple jig that i use to level the back of the headstock, and to rough out the diamond. if you look close you can see the lines i have drawn on the back of the headstock.

heres a closer look at the jig and my diamond Volute template.

The neck is held down by using double stick tape.

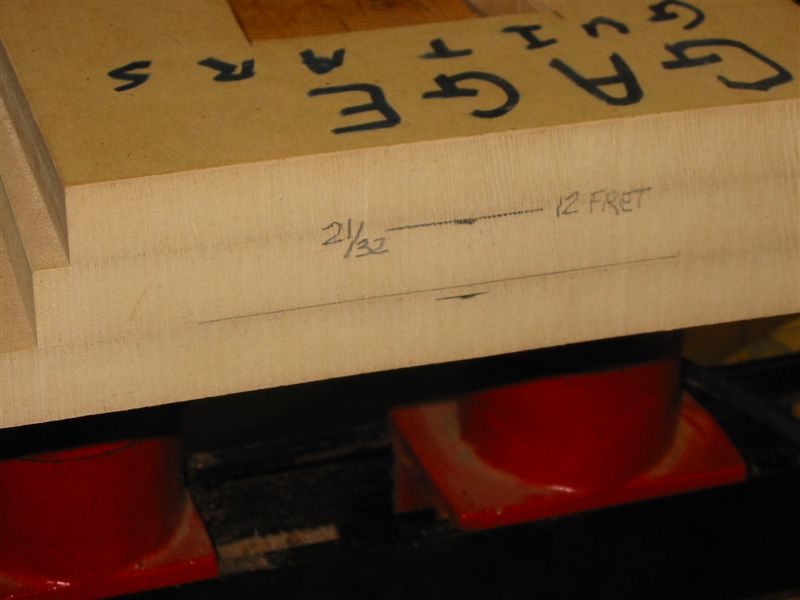

I set the router bit hight here on the outside of the jig.

Now heres where you need to be carefull, I route the whole back of the headstock and up to the lines of the volute "free hand". I get as close as possible and then clean up the lines later with my chisel.

there is still alot to do on this to clean it up... but you get the general idea.

Good luck, and have fun!

Matt