Ok, As you know I redesigned my cutaway and added it to the MJ plans. Well I did some test runs with quarter sawn straight grained Mahogany, Curly Cherry and Quilted Sapele. All orphaned or flawed sets I had laying around.

The quarter sawn Mahogany was no issue as expected.

The figured woods was an other issue.

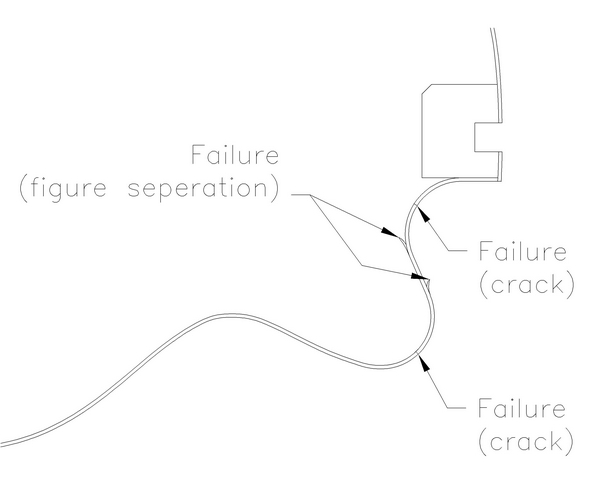

One total crack and break through on the curly Cherry. So I thinned the cutaway area to .07" Still had cracking and curl more than minor figure separation.

The quilted Sapele un-thinned .09" piece was just like the curly Cherry. The thinned piece .07" had no cracks but a good bit of figure separation.

On none of the pieces did, did I have any clue things were amiss. every thing felt as if it was bending with out issue, no sound of cracking, no abnormal resistance. The figured woods were bent at 310-315 deg f.

I have not tried Supper-SoftII on High figured wood but have some on order

Any suggestions