I am doing another segmented rosette I thought I would share my first time every time seamless box miter process and a couple of my Top Secret Weapons.

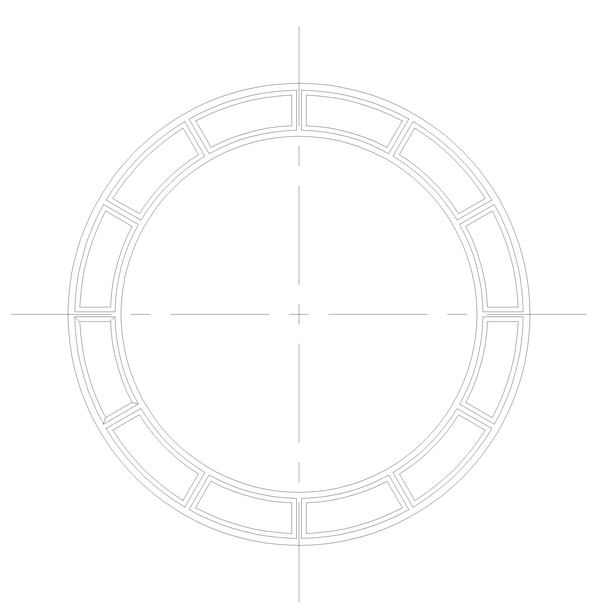

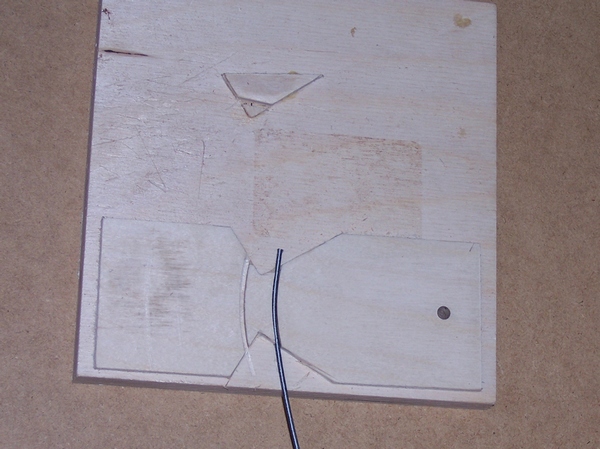

Pretty obvious how I got to this point (forming the segment that the Box miter will go around)

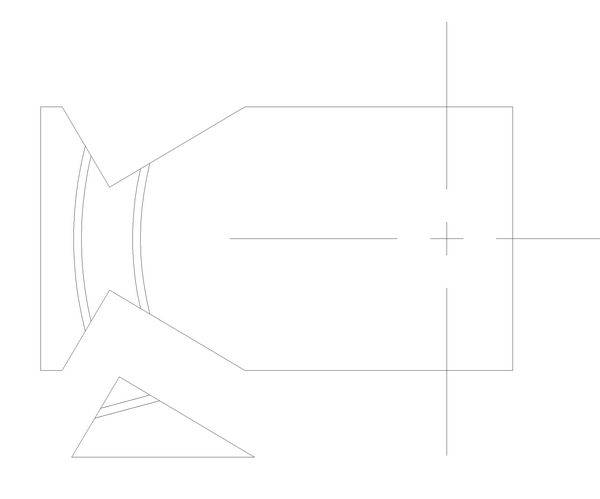

Then roll out my Top Secret Weapon #1. A simply fabricated fixture to pre-size and miter the purfling for the box miter.

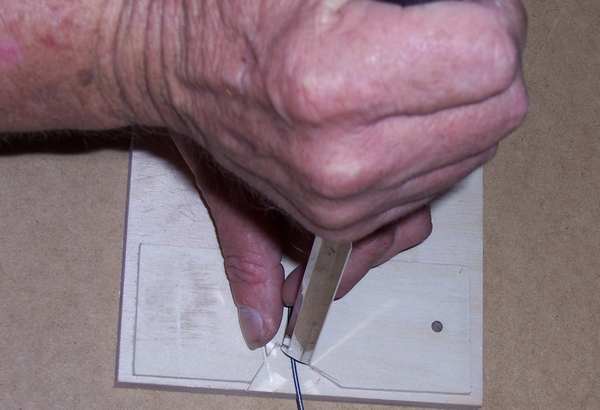

Operation of this secret weapon is simple. Insert the purfling into the channels, and chisel your miters.

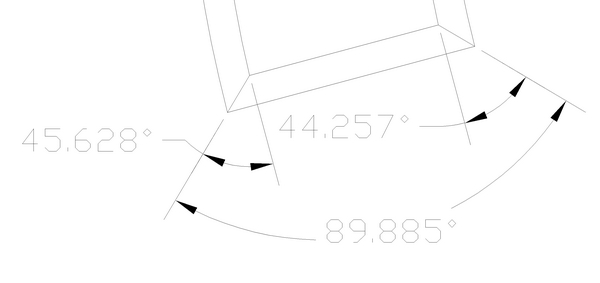

With very little effort I have the five pieces required for one segment of the 12 segment rosette i am building.

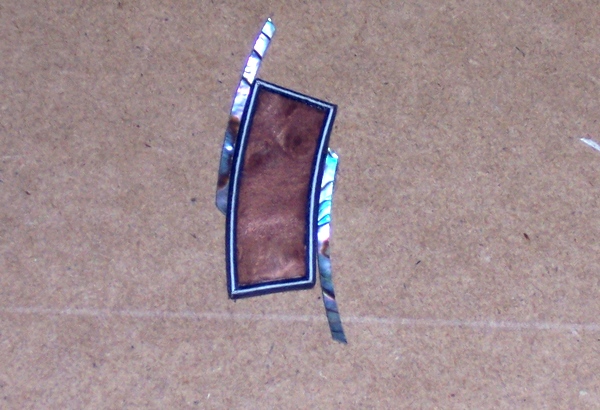

Now for Top Secret Weapon #2. A simple channel to the appropriate size of the box mitered segment routed in UHMW.

A word to the wise here. You want this to be an exact fit. Not at all loose or at all tight. Kind of the three bears just right kind of fit.

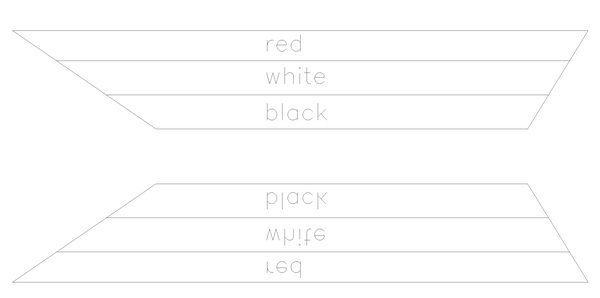

Insert the pieces and carefully and align the miter edges.

Notice the inside purfling is perfectly in place the outside piece is shifted a fraction to the right. This must be fitted in the exact position prior to glue-up to achieve a near seamless joint with the end pieces. I did not notice till after the picture was taken, but positioned it properly prior to gluing in place.

I find it works better to insert the 2 long sections and glue in place with thin CA using a fine capillary nozzle before doing the same on the end pieces.

It take very-very little CA to secure the purfling to the wood. excess CA will seep on to the miters and make it hard to fit up the end pieces so take care to use just a drop of CA in three place slightly away from where the end pieces will touch. When you glue up the end pieces you can then be a tad bit more liberal with the CA. But here again not much is needed.

And now the final product. Well not quite the final product but the first box mitered segment for this rosette. Just 11 more to go. Well actually 24 since I am building two guitars that will use this rosette.

I think this is a pretty efficient process and produces nice seamless box miters. Once3 you have built the fixtures and have gone through the glue-up process a couple times. You can crank out 12 segments in under a half hour. Try to fit 48 miters in half an hour I can do it!! with the hep of My Top Secret Weapons

I stuck the parts in the UHMW fixture and aligned but missed on the outside purfling.

I stuck the parts in the UHMW fixture and aligned but missed on the outside purfling.