Not so fast: there don't seem to be too many 'quick answers' in this business, no matter how fast the questions go by! ;)

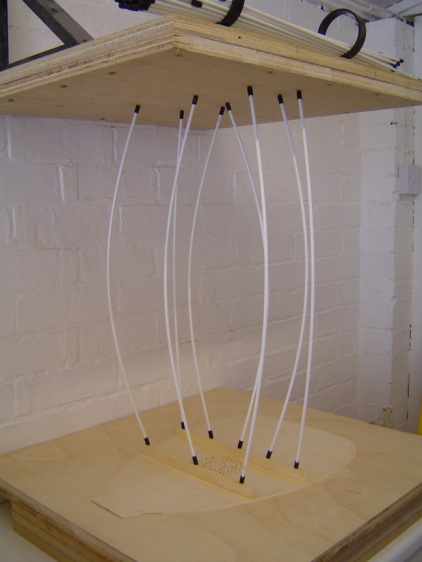

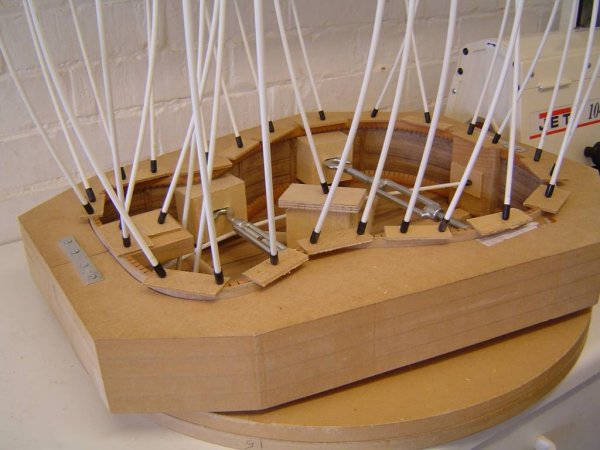

My first go-bar deck was just a piece of 3/4" ply screwed to the ceiling above one of the bench tops. The ceiling was low, but not that low! When I set up my new shop, I made the decks that same height, so that I could use all the old bars, and that's 44" off the bench top.

The longer the bars are, the less force you will get for a given thickness of go-bar. I use 5/16" dowel, and get about 8#/bar, which seems to work well for me. I'll note that the force you get from a go-bar is almost the same from the time it starts to bend until it breaks. At any rate, the lower force might be seen as a disadvantage by some. I feel that it's easy enough to use lots of them, and the low force per bar and tight spacing gives even pressure.

So, what are the advantages of a tall 'deck' like mine? One is that it gives you more of a range of heights that you can clamp with a given length bar before the bars are bent too much. Another is that it's easy to get at things on the deck; no stooping to get my head under. My decks (I have two) are simply benchtops, and can be used as such when they're not clamping something. Both of them, BTW, are peninsula benches, so it's easy to get at three sides to clean up glue and such. Also, since my ceilings now are higher than the ones in the old shop, I've built the top surfaces of the decks as the bottoms of open ended boxes, and use them to store the go-bars. All I have to do is reach up.

|