They must have tested the cfm with no filter bags, and the inlets facing

upwind in a hurricane. My old cyclone has a true 2hp 3-phase motor and

6" inlet and I estimate it at around 1200cfm.

As to rating things like horsepower, companies can get pretty creative.

Craftsman can make a shop vac with a hair drier motor that draws about

3 amps, and somehow rate it at 6 hp.

I think they can calculate the

I think they can calculate the

maximum force for HVAC systems not by force produced at the motor,

but by maximum potential energy. So if you plugged the input of a shop

vac, ran it until the motor almost burnt out, then detonated the canister I

think you might get an instant energy burst of near 6hp as it imploded. I

guess a bit of creative marketing is to be expected though. Either that, or

more likely a plain simple lie.

That aside, if it can pull 700cfm, it's fine for just about any small shop.

You just won't be able to leave more than one or two blast gates open at

a time, and it might not be enough for something like a 48" wide belt

sander. What you should be concerned about is the 30 micron bag. That

would be fine for a planer or jointer, but it would just blow most sawdust

straight through. If you're putting the dust collector outside that's fine,

but if it's going to be inside your shop you should look for a filter or bag

size of 1 or 2 microns.

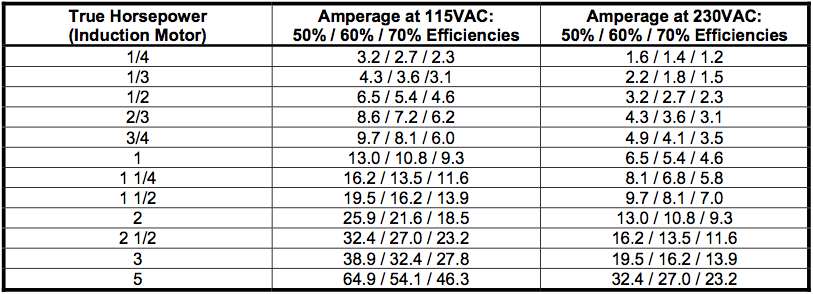

The smaller the filtering size, the less efficient and the more hp you'll

need for the same cfm. If you're stuck in a small shop I would definitely

favor the smaller filter over cfm. As long as you run your pipe cleanly and

don't leave too many blast gates open at once, I think you'll do better with

less cfm and better filtering. The Delta's seem pretty good for this, and

don't cost much more.

P.S. If you have 3-phase, I have an old Cincinnati 2hp blower that I'm

getting rid of. Trash can style cyclone, no filters or bags, and really loud,

but cheap.

It won't perform any

It won't perform any