[QUOTE=Hesh1956] Brother Bruce beat me to it

[/QUOTE]

[/QUOTE]

I was hurrying to beat the band.....

| Official Luthiers Forum! http://w-ww.luthiersforum.com/forum/ |

|

| Radius-ing Braces http://w-ww.luthiersforum.com/forum/viewtopic.php?f=10102&t=13358 |

Page 1 of 1 |

| Author: | EnFuego [ Thu Aug 23, 2007 10:08 am ] |

| Post subject: | |

I'm wanting to make a jig to make adding a radius to braces easier, but I can't figure out how to get a 15' and 25' radius onto a template. I have some radius dishes, so I guess I could just sand something to the right shape, but that seems like it would take a while, so I'm hoping somebody has a better idea. I guess I could just get a long string and attach a pencil to the end. |

|

| Author: | Bruce Dickey [ Thu Aug 23, 2007 10:18 am ] |

| Post subject: | |

Stretch a tape 25 feet, secure it. Draw an arc on a pattern at 25 feet. Cut it out on the bandsaw. Sand. There is one template. Trace onto blank brace stock. Hand plane to the lines. Finish sand in your dish. Done. |

|

| Author: | jfrench [ Thu Aug 23, 2007 10:23 am ] |

| Post subject: | |

To make a template just take a piece of stable wood, plane it until it almost fits in the radius dish and sand it in the dish until perfect. Then work off that. Or just do that for your braces. It takes me less than a minute to radius a brace (but I only have to do three per guitar). |

|

| Author: | LuthierSupplier [ Thu Aug 23, 2007 10:25 am ] |

| Post subject: | |

You can buy one of my radius gauges HERE or better yet, just get the brace maker and it will do exactly what you want. Good luck! Tracy |

|

| Author: | Bruce Dickey [ Thu Aug 23, 2007 3:52 pm ] |

| Post subject: | |

[QUOTE=Hesh1956] Brother Bruce beat me to it  [/QUOTE] [/QUOTE]

I was hurrying to beat the band.....

|

|

| Author: | Bruce Dickey [ Thu Aug 23, 2007 3:57 pm ] |

| Post subject: | |

EnFuego, I have a pair of brace making jigs. 1. One cuts the x brace notch at the perfect angle. 2. The second cuts the radius needed for the top and scallops it too. But that's in my advanced course.... Otherwise just plane by hand and finish 'em off in the dish. It's really pretty fast by hand and you save a bunch of time not having to build the jigs. Lost time is never found. |

|

| Author: | Heath Blair [ Thu Aug 23, 2007 4:08 pm ] |

| Post subject: | |

all of the above methods are reasonable, especially buying a radius gauge or brace maker from one of our fine sponsors. i personally was not satisfied with the string and pencil method, cumpiano's nail and wire method, or a handful of others as well. it took me alot of hours and some cursing, but i finally found a way that worked for me. thanks to some great folks here on the OLF! i used the "long compass" method and it worked great. here is a link to a recent thread that discusses briefly what you are trying to do. down the page a ways there is another link to the long compass method and further down still is a link to an excel spreadsheet with some of the numbers youll need to make the compass. instead of using a pencil, i actually made a jig to carry my router and used the long compass to route a perfect arc segment. man was i so happy when i figured that out. soooo much better than the other stuff i tried. and unlike the other methods, you do not have to sand down to a pencil drawn line. the arc is already perfect! feel free to PM me if you have questions. |

|

| Author: | Kelby [ Thu Aug 23, 2007 4:40 pm ] |

| Post subject: | |

A much easier way. Here's the simple way. If you want to make a 2' arc with a 25' radius, then the center of the arc must be 1/4" lower than the outside edges. (Actually, it's .24 inches lower, but 1/4" is close enough.) So you take a 2x4 and draw a straight line along one edge (it's a little more convenient if you make it about 1/2" in from the edge). For sake of reference, let's call the edge of the board closest to the line the "A" side and the edge of the board furthest from the line the "B" side. Drive two nails partially into the 2x4 that are exactly 2' apart, with the edge of each nail on the B side of the line. It is important that the nail just barely touch the line, so there is exactly 1/2" between the A edge and the edge of the nail for both nails. Now, exactly 1/2 way between those two nails, make a mark 3/4" from the "A" edge of the board. Drive another nail on the A side of the line that just barely touches the line at this mid-point between the other two nails. (Sorry this is so hard to explain; it would be nice if I could draw a picture.) Now, you need something that is fairly stiff but not completely stiff that is at least 2 feet long. A go-bar works, and so does a piece of 1/4 steel rod. Whatever kind of rod you use, you need to weave it between the nails. It should go on the "A" side of the 2 outer nails, and the "B" side of the nail in the middle. The rod should now form an arc 2 feet long with a 25' radius. Simply scribe a line along the rod to trace the arc. If you want a 15' radius, you need to move the middle nail another .15" away from the A side of the board. |

|

| Author: | BlackHeart [ Thu Aug 23, 2007 7:28 pm ] |

| Post subject: | |

Yes, I was about to say this is basic trig or something. There should be a list or table for common luthier radi, if I say so myself, as its just basic trig. 15, 16, 18, 20, 25, 28, 30 35 40 so if someone has the formula...... about halfway down? http://www.zaimoni.com/Trig.htm

|

|

| Author: | Mattia Valente [ Thu Aug 23, 2007 8:25 pm ] |

| Post subject: | |

Y'know, that long compass thing has me thinking you don't ever need to make an arched rail by sanding; make a long compass with a router bit as the 'pencil', and voila, you've got yourself a perfectly clean, square, routed radius. I can even envision an adjustable (if slightly long) router carriage with adjustable height (ie, drop-off) that would allow routing radius dishes of essentially any radius. I think I may have to go make that now, since I want some new dishes (left my old ones outside by mistake during the move, one surface not finished, and it rained a bit. Badness.) |

|

| Author: | Colin S [ Thu Aug 23, 2007 8:58 pm ] |

| Post subject: | |

Joshua is right, make it from the existing dish. That dish should be the starting reference for any 25' radius you make. Always go back to that for reference as you don't want second or third generation errors to creep in. Making a new radius with a long compass or whatever will not necessarily produce the same radius as the dish due to normal error. Not all 25' dishes are 25'! So just use the one you've got. Colin |

|

| Author: | Colin S [ Thu Aug 23, 2007 9:02 pm ] |

| Post subject: | |

EDIT! My simple brace radiusing jig was roughed out then sanded in my dishes 25' one side 15' the other. I use it with a table router. But I still finish off the braces by sanding in the dishes.

Colin |

|

| Author: | Arnt Rian [ Thu Aug 23, 2007 9:26 pm ] |

| Post subject: | |

Todd, do you have a source for upcut (for router table) spiral flush cutting bits with bottom bearings? I have only seen flush cutting spiral with bearings mounted on the end of the bit. |

|

| Author: | Colin S [ Thu Aug 23, 2007 9:40 pm ] |

| Post subject: | |

What Arnt said. By the way that bit does have a slight shear angle rather than just being straight, but I find it gives superb results and, as I said, I always want to just finish it in the dish anyway, always go back to the prime source of reference. Colin |

|

| Author: | Alain Desforges [ Thu Aug 23, 2007 10:28 pm ] |

| Post subject: | |

Like my learned friends mentioned, just use the dish you have. Just holding the blank/jig in the dish will give you a good idea of just how much you have to take off. I used a .25 thick maple board about 20 inches long by 3 inches wide. I have 15' on one side and 25' on the other. It took me about 15 minutes to do both. I also added a very little 'check' to help me register the center. Not that it helps much, but I like knowing where the exact centre of the arc is... Once you have the jig, just trace and remove the excess with a hand-plane (clean) or with a bench-top sander (not so clean) and voila! |

|

| Author: | Mark Hanna [ Thu Aug 23, 2007 10:58 pm ] |

| Post subject: | |

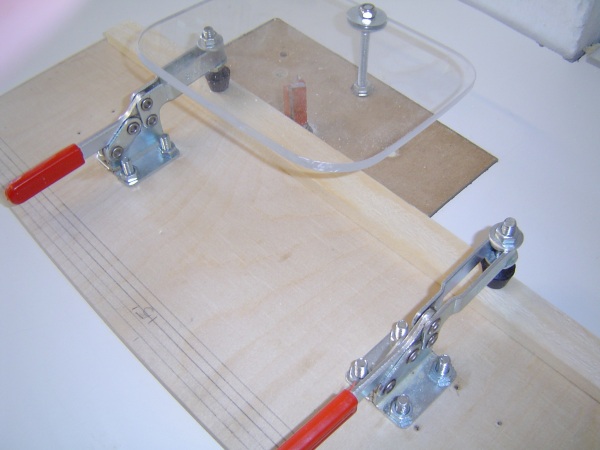

Here is the jig I use for radiusing my braces. |

|

| Author: | Arnt Rian [ Thu Aug 23, 2007 11:25 pm ] |

| Post subject: | |

Here's something different: Sylvan Wells elegant solution for cutting curved braces on a table saw, check it out: Wells jig to cut the curvature of braces |

|

| Author: | EnFuego [ Fri Aug 24, 2007 4:57 am ] |

| Post subject: | |

Thanks everyone. I think I am going to make a jig similar to the ones posted by Colin and Mark. I guess I will just make a template using my radius dishes and transfer that to the jig, so I can rough cut it from there and sand it to smoothness. Colin, do you just unscrew and reverse the clamps when using the other side? |

|

| Author: | Alan Carruth [ Fri Aug 24, 2007 5:30 am ] |

| Post subject: | |

Man, I keep telling people the easy way, and they end up making complicated jigs anyway! Sigh. Think about this: you're standing on the sea shore, looking out at a calm ocean. How far away is the horizon, and why? Well, it turns out that for most of us it's about 6 miles. The distance is fixed by the curve of the earth, and by how tall you are: the straight line of sight intersects that curved surface at a particular distance. Now, suppose you think about that curve as the surface of a brace, and the 'line of sight' is the sole of your plane. You can glue a shim to the sole in back of the cutter, and the radius will be a function of how far back the shim is, and how tall it is, assuming you're taking a very fine cut, so that the contact point (the 'horizon') is right in front of the cutter. I use a 1/16" thick shim. For a 25' radius the shim is 110mm back from the front of the throat, and for a 15' radius, 85mm. This can be calculated, but it will still take a little trial and error to get it just right, owing to the thickness of the shaving. Check the pieces in you dish. In use, I clamp three or four braces together, and start planing so that the cutter is well back from the center of the length of the brace to begin with. At first it only snipes the end, but the cut works its way back as you plane. Switch ends from time to time, and, as you get close to finished, back off on the cut as much as possible. It takes less than ten minutes to do a whole batch of bracing, once you have everything figured out. There are two possible problems: ending up with a pointed 'Gothic' arch, and rolling off to one side. You avoid the first by making sure you start the cut well back past the center of lenght, as mentioned. The second is simply a matter of good plane technique. It's easy to check for rolling by picking up the braces, still clamped together, and rocking them on the curved surface across something level and flat. You'll quickly find out if they tend to roll off to one side, and the correction is usually pretty easy. The biggest advantage of this method is that it is very simple: you just stick a shim on your plane with CA. It gives accurate results, once you've figured out where the shim goes (scribe the sole of the plane, and don't lose the shim!). The surface is planed; the best possible gluing surface. |

|

| Author: | Mattia Valente [ Fri Aug 24, 2007 6:45 am ] |

| Post subject: | |

Alan: I've tried, but I can't get it to work like it'd like it to, so I stick the radiussing with sandpaper option. I've since improved my planing technique (and quality of my planes), so maybe I'll try it again, because it seems appealing. Colin: Agreed, comments were kinda double; I'd either do a radiussed dish using my weird contraption that exists solely in my mind for now, and use that as the reference, or I'd make a long compass-with-router-bit-pencil and use that to make my dish the 'old-fashioned' way. Ultimately, your dish's shape is the arch you're using, no matter whether it's a perfectly accurate 25' dome. As long as it's symmetrical, radially, it doesn't matter. |

|

| Author: | Colin S [ Fri Aug 24, 2007 8:49 am ] |

| Post subject: | |

[QUOTE=EnFuego] Colin, do you just unscrew and reverse the clamps when using the other side?[/QUOTE] Yes, I make up a batch of 25' blanks, undo the bolts turn it round and do a batch of 15'. I've been meaning to make another one for years so I don't have to, but somehow it's never seemed to be worth the time. Mattia, it doesn't matter if your dish is 25', 24' or 24.5' whatever, if you always use it for reference. I'm not really sure what mine is, it started out as a CAD 25' circle when I transferred it to the rails for my router, but errors creep in all the way along in the process, so I doubt it's 25' precisely, but if I always use it for reference it doesn't matter. Colin Colin |

|

| Author: | Sam Price [ Fri Aug 24, 2007 9:11 am ] |

| Post subject: | |

[QUOTE=Alan Carruth] Man, I keep telling people the easy way, and they end up making complicated jigs anyway! Sigh. Think about this: you're standing on the sea shore, looking out at a calm ocean. How far away is the horizon, and why? Well, it turns out that for most of us it's about 6 miles. The distance is fixed by the curve of the earth, and by how tall you are: the straight line of sight intersects that curved surface at a particular distance. Now, suppose you think about that curve as the surface of a brace, and the 'line of sight' is the sole of your plane. You can glue a shim to the sole in back of the cutter, and the radius will be a function of how far back the shim is, and how tall it is, assuming you're taking a very fine cut, so that the contact point (the 'horizon') is right in front of the cutter. I use a 1/16" thick shim. For a 25' radius the shim is 110mm back from the front of the throat, and for a 15' radius, 85mm. This can be calculated, but it will still take a little trial and error to get it just right, owing to the thickness of the shaving. Check the pieces in you dish. In use, I clamp three or four braces together, and start planing so that the cutter is well back from the center of the length of the brace to begin with. At first it only snipes the end, but the cut works its way back as you plane. Switch ends from time to time, and, as you get close to finished, back off on the cut as much as possible. It takes less than ten minutes to do a whole batch of bracing, once you have everything figured out. There are two possible problems: ending up with a pointed 'Gothic' arch, and rolling off to one side. You avoid the first by making sure you start the cut well back past the center of lenght, as mentioned. The second is simply a matter of good plane technique. It's easy to check for rolling by picking up the braces, still clamped together, and rocking them on the curved surface across something level and flat. You'll quickly find out if they tend to roll off to one side, and the correction is usually pretty easy. The biggest advantage of this method is that it is very simple: you just stick a shim on your plane with CA. It gives accurate results, once you've figured out where the shim goes (scribe the sole of the plane, and don't lose the shim!). The surface is planed; the best possible gluing surface. [/QUOTE] Alan.....THANKS!!! Printing this one out as I type. |

|

| Page 1 of 1 | All times are UTC - 5 hours |

| Powered by phpBB® Forum Software © phpBB Group http://www.phpbb.com/ |

|