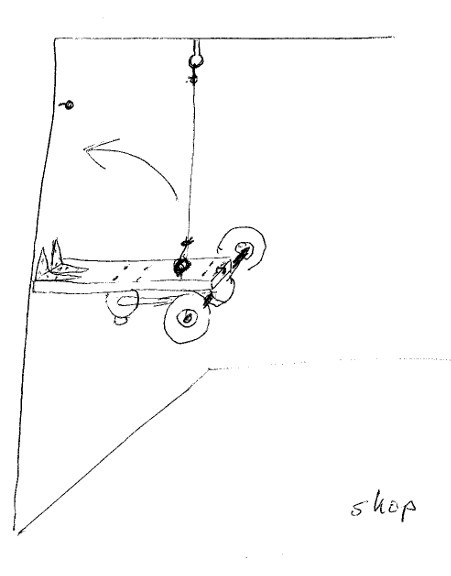

Hmm, great minds must think alike! Is this what you are referring to? I have this old stand but wasn't sure it would be sturdy enough to take the torque of the buffer and motor without walking away on me. So the weight of the 3/4 wood is enough to keep it in place? That would be the way to go if it's sturdy enough. I guess I could also bolt to the floor if need be, but I think I'll try your way first.

Cheers!

John