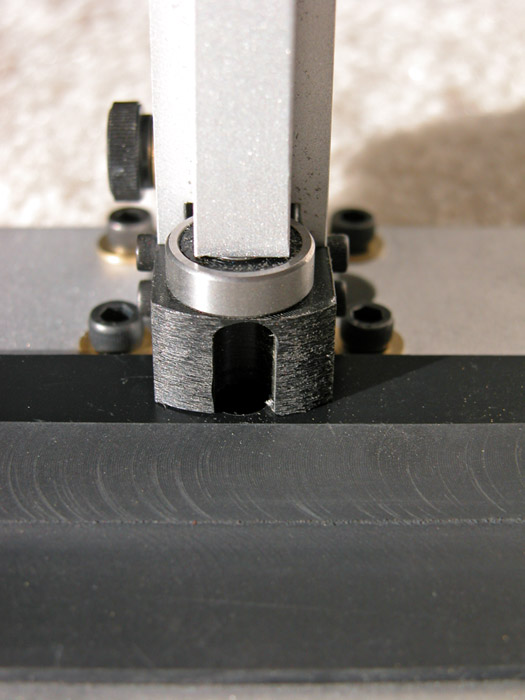

As promised, here are some pics of the Cochran prototype. I still have to build a cradle before I can test it. I'll post a review asap.

| Official Luthiers Forum! http://w-ww.luthiersforum.com/forum/ |

|

| Binding Jig pics http://w-ww.luthiersforum.com/forum/viewtopic.php?f=10102&t=13421 |

Page 1 of 2 |

| Author: | Jimmy Caldwell [ Tue Aug 28, 2007 11:49 am ] |

| Post subject: | |

As promised, here are some pics of the Cochran prototype. I still have to build a cradle before I can test it. I'll post a review asap. |

|

| Author: | Tim McKnight [ Tue Aug 28, 2007 12:01 pm ] |

| Post subject: | |

It looks like the one that Taylor uses. |

|

| Author: | Michael Dale Payne [ Tue Aug 28, 2007 12:29 pm ] |

| Post subject: | |

Thanks Jimmy |

|

| Author: | Michael Dale Payne [ Tue Aug 28, 2007 12:32 pm ] |

| Post subject: | |

Hummm????? the bearings are off center from the bit in the plane of adjustment |

|

| Author: | Heath Blair [ Tue Aug 28, 2007 1:51 pm ] |

| Post subject: | |

parallax? |

|

| Author: | jmanter [ Tue Aug 28, 2007 4:10 pm ] |

| Post subject: | |

Speaking of binding jigs, is John still building the Williams jigs? Haven't heard anything in a while... |

|

| Author: | Steve Saville [ Tue Aug 28, 2007 4:27 pm ] |

| Post subject: | |

Maybe I'm missing something, but it looks like this jig will make inconsistent depth of cuts unless it is held perpendicular to the sides in both planes. The two bearings will take care of one plane, but the other will need to be controlled by hand/eye. As soon as it is off perpendicular, the cut will be deeper than intended. If your bindings are typical .080" X .250", the .250" cut will be fine, but the .080" will be a problem. Unless I'm missing something......... |

|

| Author: | Steve Saville [ Tue Aug 28, 2007 4:29 pm ] |

| Post subject: | |

Edit - the cut will be more shallow than intended. |

|

| Author: | PaulB [ Tue Aug 28, 2007 5:00 pm ] |

| Post subject: | |

I think that the round bit of white plastic is slightly conical, so it only rides on the inner 1/8" or so of the plastic thingy. I made one that's not as pretty, and the surface that indexes against the back and top must be small or you'll get shallow ledges as you say Steve. A concial surface with a flat area in the centre is a nice way around this problem. |

|

| Author: | Arnt Rian [ Tue Aug 28, 2007 5:02 pm ] |

| Post subject: | |

You are right Steve, that is one of the realities with this type of jig. (Well, not the "dumbell" type which has contact points with the same OD as the cutter which takes care of the problem. They can't use spiral bits though). However, in reality is is quite simple to keep the cutter/bearing axis perpendicular to the side of the instrument, and if you do a few passes you can be sure the cut is quite even. |

|

| Author: | Arnt Rian [ Tue Aug 28, 2007 5:04 pm ] |

| Post subject: | |

Paul, we posted at the same time. It seems we had read Steve's question diffrently... |

|

| Author: | PaulB [ Tue Aug 28, 2007 5:17 pm ] |

| Post subject: | |

Yeah Arnt Mate, I think I had it wrong. You do need to have a small footprint on the top bearing surface or the jig will ride up on the dome of the top and back. But as you say, multiple passes are the key if you aren't holding it square all the time. Incidently; I found I had some chipout with spiral downcut bits. seems that if all the chips are being pushed downwards, they chip the edge of the ledge. Is that what you were talking about Arnt? |

|

| Author: | Arnt Rian [ Tue Aug 28, 2007 5:31 pm ] |

| Post subject: | |

Hi Paul, no I was talking about the depth of the cut. As Steve noted, if you don't keep the axis of the cutter and bearing perpendicular to the side of the instrument, the rabbet will end up being more shallow. As I said, a couple of passes will usually take care of the problem. As for the direction of the cut, this jig will be no diffrent than with other jigs, you have to pay attention to the grain of the wood. I cut from the widest parts of the bouts down towards the waist and end blocks. I like downcut spiral bits, I think they cut cleaner than regular rabbet bits. |

|

| Author: | Bobc [ Tue Aug 28, 2007 10:01 pm ] |

| Post subject: | |

Jimmy that is a fine job. Looks like it was made professionally. Justin John Hall is making the Williams jig and in fact has some ready to sell. |

|

| Author: | Tim McKnight [ Wed Aug 29, 2007 12:21 am ] |

| Post subject: | |

Jimmy, I would think that you might want to consider adding a jam nut to the threaded depth of cut adjustment rod to keep it from moving during the cut. |

|

| Author: | Michael Dale Payne [ Wed Aug 29, 2007 12:24 am ] |

| Post subject: | |

You have to get out of your minds eye the fact that the adjustment and the D handle are not on the plane of action and keep the bearings and bit perpendicular to the body. That said; This setup is a bit weird to me because having the adjustment plane offset means the amount you adjust is not directly equal to the amount of depth adjustment you impart. I like the handle idea but I would want the plane of adjustment to be perpendicular to the cut rather than not quite tangent as this tooling is. The handle ma be in an ergonomic location, I am not sure about that. |

|

| Author: | Michael Dale Payne [ Wed Aug 29, 2007 12:35 am ] |

| Post subject: | |

I guess I should have said what it is that bothers me is the fact the the as you adjust the bearing in or out, because the adjustment nut/bearing center plane is no in line with the bit/bearing plane. as you adjust this in or out you effectively alter the relationship between the D handle and the proper line of action of the cut. Now we are talking thousandths of an inch but none the less when cutting binding channels we deal with thousandths of an inch. |

|

| Author: | letseatpaste [ Wed Aug 29, 2007 12:37 am ] |

| Post subject: | |

SteveS is right, the width of the cut will be inconsistent if you don't hold it perpendicular. In another thread, I even did some cad drawings to illustrate that, when I was looking for a binding jig. Turns out, in real life it's not really much of an issue. You just take a few finishing passes and it turns out fine. I suspect the bearings are in the plane of adjustment, I think our eyes are just playing tricks. I like that the bit is not surrounded by plastic like on my luthiertool jig. I think next time, I may actually remove that piece of plastic and see how it goes. It's the black plastic piece above the bearing in Hesh's photo below (jig is updside down in photo), for me it can get packed with saw dust.

|

|

| Author: | Mike Mahar [ Wed Aug 29, 2007 12:37 am ] |

| Post subject: | |

MichaelP, I think you are looking at an optical illusion. If you look at the screws that secure the plastic plate to the base you will see that they are in line with the handle and the center of the bit. The base of the handle is also in the same line with the bearing and the bit itself. The close-up does look like the adjustment is off center but I don't think that that is the case. |

|

| Author: | Jimmy Caldwell [ Wed Aug 29, 2007 1:27 am ] |

| Post subject: | |

Just to clarify. Mike is right, the center of the bit and the entire adjustment mechanism are all in line. It's just the angle of the photograph that makes it appear offline. And Bob, I wish I could take credit for this, but the only part that I built is the UHMW donut which is conical with a 1/8" flat spot on the bottom to compensate for the top/back arch. Bishop Cochran built the tool(See first line of the original post). |

|

| Author: | Jimmy Caldwell [ Wed Aug 29, 2007 1:32 am ] |

| Post subject: | |

Tim, there is a hex head set screw that locks each of the two adjustment rails on the other side. |

|

| Author: | Michael Dale Payne [ Wed Aug 29, 2007 1:49 am ] |

| Post subject: | |

Wow I have looked very close at all three pics it looks off center to me but I finally figured out that the bearings are a bit higher than the tip of the bit. This in combination with the angle of the photos is what was making it look off center. You said this is a prototype. Do you know if it will be retail available soon. The only thing I dislike about my Luthier's tool model is I would like a better grip at the bearings but it really is not much of an issue. |

|

| Author: | TonyKarol [ Wed Aug 29, 2007 2:06 am ] |

| Post subject: | |

Michael ... I have one of the LT jigs as well, used it once and really didnt like the feel compared to my shopbuilt versions, which have substantially more heft to them on the shoe/bushing side of things. It was a simple fix on the LT model .. quick trip to the local metal supermarket, 4 bucks worth of scrap alum plate and some 1/4 20 hex bolts,. threaded into the existing LT handle and thats it - now the whole thing balances much beter,and feels like my other ones. seems to me anyone with an LT jig could make and bolt a handle like this one in about an hour ... |

|

| Author: | Arnt Rian [ Wed Aug 29, 2007 3:01 am ] |

| Post subject: | |

Like I mentioned in the thread about my version of this jig, I clamp the jig in a vise with the router and bit horizontally. I hold the guitar with both hands and slowly rotate it while it registers firmly against the contact points of the jig. I tried using it hand held, but I found the tendency of the tool to tip over to be annoying and cumbersome and just one more thing to keep an eye on while operating it. Both the Taylor and Martin factories use a version of this jig and "feed the guitar to the tool" and not the other way around. I really think it's the best way. |

|

| Page 1 of 2 | All times are UTC - 5 hours |

| Powered by phpBB® Forum Software © phpBB Group http://www.phpbb.com/ |

|