I think you need more gobars on there.

| Official Luthiers Forum! http://w-ww.luthiersforum.com/forum/ |

|

| Bridge Plates (Pic) http://w-ww.luthiersforum.com/forum/viewtopic.php?f=10102&t=13444 |

Page 1 of 2 |

| Author: | jhowell [ Wed Aug 29, 2007 12:01 pm ] |

| Post subject: | |

Hesh-- Very clean work as usual! I'd be interested in hearing the pro's and con's of sanding in the radius. Quite frankly, I haven't done this and am wondering if maybe I should be. |

|

| Author: | joe white(old) [ Wed Aug 29, 2007 12:27 pm ] |

| Post subject: | |

I think you need more gobars on there.

|

|

| Author: | KenH [ Wed Aug 29, 2007 2:33 pm ] |

| Post subject: | |

Nice clean work Hesh! I also radius my bridge plates. I dont go to the trouble of champhering the edges though. I use a radiused caul when gluing them in place. BRW is a good choice of woods also. As you know I have been using Osage Orange lately and I like the results I am getting. I prefer ths wood because it is so dense and rugged. I dont think I will have problems with the string balls causing damage to this plate even with someone who changes strings daily. I think you wont have any problems with bridge plate wear either. Grain orientation is important also. I think having good contact with the x- braces is important. Looks like you are doing all of the right things! |

|

| Author: | Kent Chasson [ Wed Aug 29, 2007 5:09 pm ] |

| Post subject: | |

I agree that they are important. My opinion about bridge plates is informed mostly by trying about 6 different versions on the same test top. On my particular test tops, switching from a fairly traditional maple plate to brazilian gave me more of everything in the sound but particularly clearer bass and more brilliant treble. I also tried eliminating the plate entirely except for a small oval under the pins. The result again, to my surprise, was a little more of everything and a lot more string noise! Serious squeeking. I then swapped out the bridge for a heavier, stiffer one and the string noise was reduced. One lesson, yet again, is that the bridge plate is part of a system. The effect of the bridge patch is partly dependent on the bridge, top thickness, and brace stiffness in the area. For example, I know some folks build with thin tops and use an oversized patch as a brace to prevent over bellying of the top. But would an oversize patch be an asset to a thicker top? I doubt it. Fun stuff! |

|

| Author: | PaulB [ Wed Aug 29, 2007 5:25 pm ] |

| Post subject: | |

[QUOTE=Kent Chasson] I also tried eliminating the plate entirely except for a small oval under the pins. The result again, to my surprise, was a little more of everything and a lot more string noise! [/QUOTE]So does that mean the guitar was more responsive in general? Maybe too responsive? Does that mean some dampening at the bridge/bridge plate is desirable? No matter how much I try to keep work (science) out of guitar making it always seems to creep back in. One experimental result only leads to more questions

|

|

| Author: | John Mayes [ Wed Aug 29, 2007 9:42 pm ] |

| Post subject: | |

I'd be careful using brazilian as a bridge plate. Although it may add some zing to the tone which can be great it is, as you know, very prone to splitting, and replacing a bridge plate after the fact is not an enviable project. I think indian is a much better choice if you must have rosewood as it is far more stable. |

|

| Author: | Colin S [ Wed Aug 29, 2007 10:31 pm ] |

| Post subject: | |

A couple of things. Firstly I agree with John about BRWs tendency to split, I'm still a maple man for bridge plates, but EIR or Honduran would be a better choice, Osage orange is prefered by some. I always add a bone veneer to mine anyway. Seconly like Todd said, do use a caul to even out the pressure over the thin wood. I use one from HMWP that glue won't stick to, I believe SM sells them though I just cut up a chopping board. I use just half a dozen bars, nearly 50lb of pressure is plenty. Colin |

|

| Author: | Marc Lupien [ Thu Aug 30, 2007 12:23 am ] |

| Post subject: | |

Colin, could you elaborate on the "bone veneer"? Thank's Marc |

|

| Author: | Colin S [ Thu Aug 30, 2007 12:45 am ] |

| Post subject: | |

Marc, my bridge plates always have a thin piece of bone where the pins pass through and the string ball ends butt against. I originally did this to save having to renew a bridgeplate on my '33 Martin OOO. Now I add it to all my guitars. Think of Stew Mac's Plate Mate, but instead of brass I make mine a bit bigger and from bone. The way I see it, the strings are then held on a bone nut, bone saddle, bone pins, bone plate. Retro-fitting is easy, and there's a definite improvement in sustain and clarity. Try it on an old guitar, they don't even have to be glued in, the ball ends wil hold it. Colin |

|

| Author: | Dave Rickard [ Thu Aug 30, 2007 1:18 am ] |

| Post subject: | |

[QUOTE=Colin S] I always add a bone veneer to mine anyway. Colin [/QUOTE] Colin, Would you expand a little on the bone veneer? |

|

| Author: | KenH [ Thu Aug 30, 2007 1:28 am ] |

| Post subject: | |

where do you get bone that wide and thin? |

|

| Author: | Michael Dale Payne [ Thu Aug 30, 2007 1:44 am ] |

| Post subject: | |

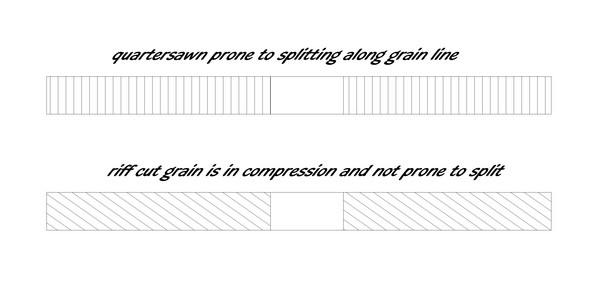

No one mentioned the skewed or riff cut as being important in avoiding splitting. I use mostly riff cut maple though I have used some BRW. |

|

| Author: | Kent Chasson [ Thu Aug 30, 2007 2:18 am ] |

| Post subject: | |

[QUOTE=PaulB] So does that mean the guitar was more responsive in general? Maybe too responsive? Does that mean some dampening at the bridge/bridge plate is desirable? Yes, more responsive, louder, more immediacy, more clarity. Maybe too clear and metalic. Not sure about the damping. Maybe there's another way to get rid of the string noise. I'd consider using that approach if I ever build another instrument for someone who plays with flat wound strings to give back some of the life lost with those things. As for splitting, I just make sure not to use quarter sawn wood and I don't run the grain parallel to the holes. Cocobolo works well too. |

|

| Author: | Michael Dale Payne [ Thu Aug 30, 2007 3:11 am ] |

| Post subject: | |

[QUOTE=Kent Chasson] As for splitting, I just make sure not to use quarter sawn wood and I don't run the grain parallel to the holes. Cocobolo works well too. [/QUOTE]If you have quartersawn piece of wood with the grain running vertical (as in ||||||||) and a hole drilled vertically through that plate there is on way the grain could ever be anything but perpendicular to the hole. I does not mater which way you orientate the grain it is still prone to splitting along grain line. Now if you are saying that you use quartersawn with the grain in the horizontal position it will not be subject to splitting but I would imagine it wold be more dampening Someone correct me if I am wrong here. |

|

| Author: | WaddyThomson [ Thu Aug 30, 2007 3:15 am ] |

| Post subject: | |

[QUOTE=Hodges_Guitars]where do you get bone that wide and thin?[/QUOTE] I've seen some 4 1/2" x 1/2 x 1/8' saddle blanks. Seems like that might work. |

|

| Author: | Michael Dale Payne [ Thu Aug 30, 2007 3:16 am ] |

| Post subject: | |

If you have quartersawn piece of wood with the grain running vertical (as in ||||||||) and a hole drilled vertically through that plate there is on way the grain could ever be anything but perpendicular to the hole. It does not mater which way you orientate the grain it is still prone to splitting along grain line. Now if you are saying that you use quartersawn with the grain in the horizontal position it will not be subject to splitting but I would imagine it wold be more dampening |

|

| Author: | Michael Dale Payne [ Thu Aug 30, 2007 3:24 am ] |

| Post subject: | |

If you have quartersawn piece of wood with the grain running vertical (as in ||||||||) and a hole drilled vertically through that plate there is NO way the grain could ever be anything but perpendicular to the hole. It does not mater which way you orientate the grain it is still prone to splitting along grain line. Now if you are saying that you use quartersawn with the grain in the horizontal position it will not be subject to splitting but I would imagine it wold be more dampening |

|

| Author: | Michael Dale Payne [ Thu Aug 30, 2007 3:44 am ] |

| Post subject: | |

With quartersawn the grain is running vertical or in the same plane as the hole. Due to loading this makes the grain more likely to split. With riff cut the grain is being pressed into its self and far less likely to split along a grin line. |

|

| Author: | Arnt Rian [ Thu Aug 30, 2007 4:03 am ] |

| Post subject: | |

[QUOTE=MichaelP]Now if you are saying that you use quartersawn with the grain in the horizontal position [/QUOTE] You mean flat sawn? [QUOTE=MichaelP]it will not be subject to splitting but I would imagine it wold be more dampening [/QUOTE] Why do you think so? |

|

| Author: | Michael Dale Payne [ Thu Aug 30, 2007 4:38 am ] |

| Post subject: | |

there is a bit of a difference in typical flatsawn and true quartersawn laid in the horizontal position. I would suspect that quartersawn laid flat would dampen the energy being transmitted into the top because the grain line structure would be dead perpendicular to the tops grain structure. I could be wrong here. but I don't think so. |

|

| Author: | Michael Dale Payne [ Thu Aug 30, 2007 5:17 am ] |

| Post subject: | |

That is what I was taught. I have never used a qs piece for a bridg plate. |

|

| Author: | Marc Lupien [ Thu Aug 30, 2007 5:31 am ] |

| Post subject: | |

Thank you Colin, One more question if I may. Do you inlay the bone piece in the plate or if you laminate the bone on top of the plate? TIA Marc |

|

| Author: | Kent Chasson [ Thu Aug 30, 2007 5:47 am ] |

| Post subject: | |

Michael, I think you misread my post. I said I make sure not to use quarter sawn. And I said not parallel to the holes (plural) meaning parallel to the line of holes. By the way, thanks for the bone idea, Colin. I'm going to give that a try. Also, for those of you that heat parts for hide glue, do you ever worry about humidity issues? We all go to such lengths to control humidity for glue ups that I've never been comfortable with the idea of heating parts and potentially drastically changing the relative humidity, particularly for plates. But I know a lot of folks do it so is it not an issue and why? |

|

| Author: | Michael Dale Payne [ Thu Aug 30, 2007 6:11 am ] |

| Post subject: | |

yep I miss read it

|

|

| Page 1 of 2 | All times are UTC - 5 hours |

| Powered by phpBB® Forum Software © phpBB Group http://www.phpbb.com/ |

|