I think it was ultimately someone with the handle psl something, that posted a pick for me of his radiusing jig that made the light bulb click in my head (thanks for that psl) and now making my own radius dishes is a snap.

I am hoping for such success on a fretting jig.

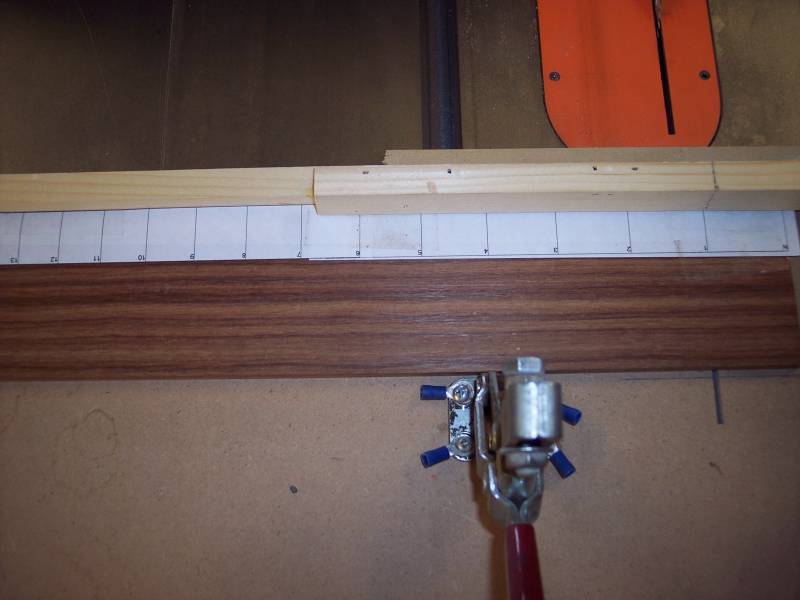

I saw a pic somewhere, but can't seem to find the right key words to find it in the archives. What I am looking for is some pics of jigs ya'll use to fret finger boards using the thin kerf blades on a table saw. I recently was given a nearly new blade by a local repair man (6 inch 110 tooth count, super thin kerf) for the table saw.

I remember someone's jig resembling a sled on the table saw with a mark for where the cut is made, attaching a scale guide to the finger board and moving it to align with the cut mark. I am trying to figure out the best way to attach the board to the scale guide, maybe tape?

Pics would be so much appreciated, I guess i am a visual learner.

thanks,

jon

|