The amount I'm talking about (and Mario uses) is really pretty minimal, and in terms of 'tap tone resonance', I don't hear huge/significant differences. Certainly not in terms of damping and/or ring, although I'll do a little more testing when I get the big stuff laminated up (X-braces, which is where I'm using it). Keep in mind I'm talking loose sticks of binding right now, not the easiest things to tap. The goal is to add enough CF to get rid of a memory effect, and longer term deformation (ie, bellying), not to add massive amounts of stiffness, if any at all.

We put CF in necks, after all, and I like what it does to those (mine resonate longer and at a slightly higher pitch, good sustain, after I glue the bars in compared to before gluing in the bars. It's selective stiffening that affects the main vibrational modes, but for necks at least, it does it in a way I like.

Anyway, I'll shut up about it now until I've actually finished a guitar with CF braces in it.

|

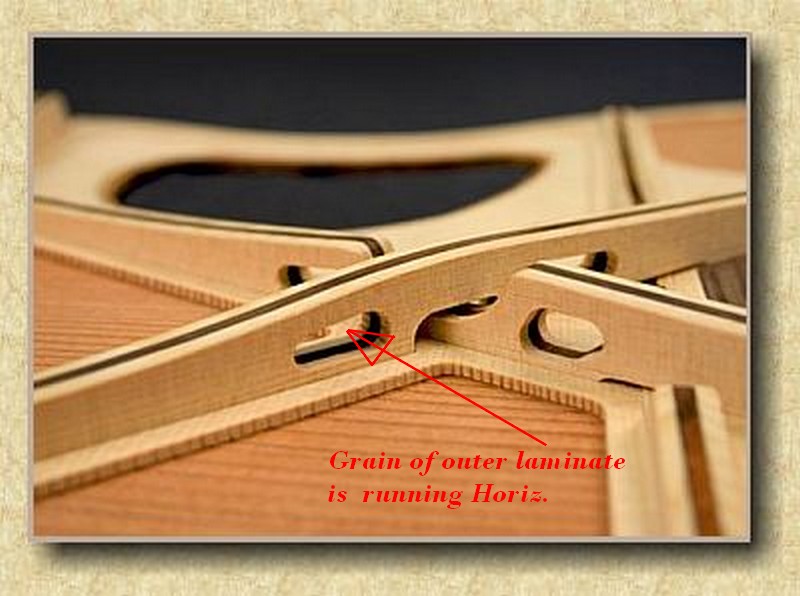

It looks to me like all the grain in the photo is going horizontally, just like a normal brace. Are we looking at the same photo?

It looks to me like all the grain in the photo is going horizontally, just like a normal brace. Are we looking at the same photo?