I don't know why the picture didn't load. Here it is again.

| Official Luthiers Forum! http://w-ww.luthiersforum.com/forum/ |

|

| Detecting Runout http://w-ww.luthiersforum.com/forum/viewtopic.php?f=10102&t=13541 |

Page 1 of 1 |

| Author: | SimonF [ Thu Sep 06, 2007 3:04 pm ] |

| Post subject: | |

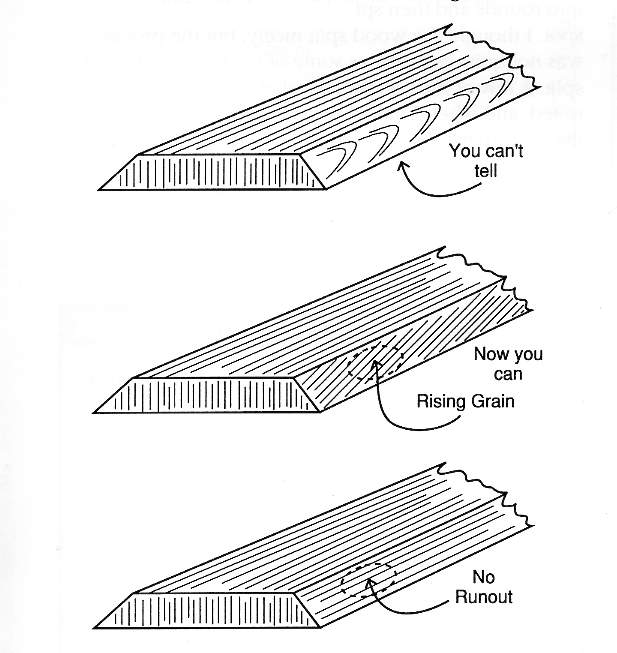

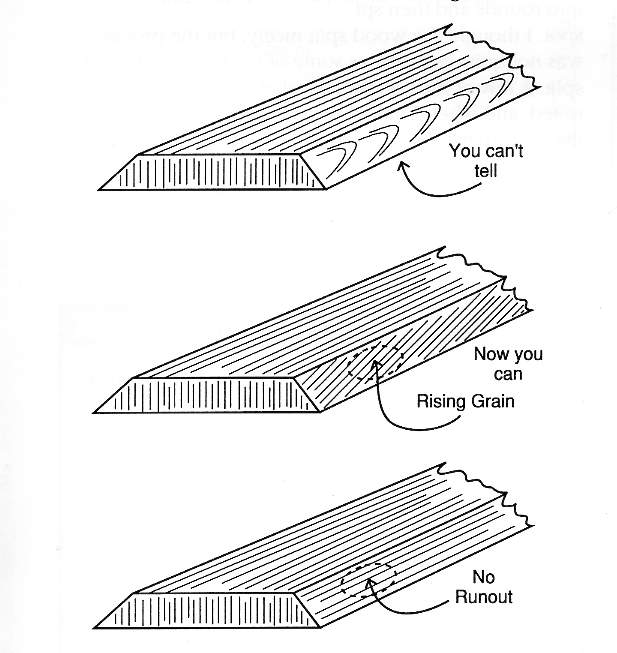

Hey Everybody, When resawing some old growth and hand split billets of Western Red Cedar, I thought I would try the beveling method for detecting runout. I never put much thought into the method but after a little thinking, I realized that this method does NOT detect runout and should not be used for verification. There is a small picture of the method below for those who haven't heard about it. The only thing this method does for quartersawn wood with distinct annular growth lines is show the lengthwise movement of the grain. By that, I mean if the grain lines are perfectly straight and stay parallel to the bevel, you will see the lines run straight along the bevel. But if the grain lines move to the right or left they will appear to move up or down on the bevel face. Supposedly, this is how you detect runout. But the direction and movement of the grain lines on the bevel face is entirely unrelated to runout. If you disagree, please test this yourself. It only takes a few minutes to verify and if you stop and ponder it, I think it is fairly obvious. After all the growth lines are like "sheets" of wood not "strands" of wood. This means that regardless of how much runout is in the piece, a beveled edge will show perfectly straight grain as long as the grain runs parallel to the bevel. The only methods I know to detect runout are 1) visually on bookmatched sets 2) via touch which doesn't seem to be very reliable 3) the best and only real method is to split a piece of the billet or set and see how the grain breaks. This just goes to show that the "tonewood lumberjack" is the really important part - it is up to them to cut the wood so that any runout is minimalized. [IMG]../forum/useruploads/SimonF/2007-09-07_000402_Runout.jpg[/ IMG] |

|

| Author: | SimonF [ Thu Sep 06, 2007 3:05 pm ] |

| Post subject: | |

I don't know why the picture didn't load. Here it is again.

|

|

| Author: | SimonF [ Thu Sep 06, 2007 3:14 pm ] |

| Post subject: | |

One last thing I wanted to mention. When I was messing around with this method today, it initially makes a lot of sense. But when you think about it more, it starts to break down and you realized that it really doesn't. I remember seeing this photo of a top with extreme runout. If you took this board and planed the edge, the runout would no longer be visible. All you would see would be the growth lines running fairly straight down the board. So an easy way to test this piece for runout would be to cut off a 1" section at the edge (or however much you could spare) and try and split the grain with a fine chisel. You would then easily see the runout and it would once again look very similar to the picture. So once again, the bevel method doesn't work. Just thought I would mention this because I never thought to question it and have been relying on it for the last year or so.

|

|

| Author: | Brock Poling [ Thu Sep 06, 2007 3:15 pm ] |

| Post subject: | |

Interesting... that image came from an old Guitarmaker mag, and Craig Carter wrote it. Thanks for the observation. |

|

| Author: | jfrench [ Thu Sep 06, 2007 10:13 pm ] |

| Post subject: | |

I totally agree that the best way is to split a piece of what you are using. |

|

| Author: | Daniel M [ Fri Sep 07, 2007 4:30 am ] |

| Post subject: | |

There's an easier way to detect runout in a quartersawn piece of wood. Look at the end grain & note the verticality of the grain lines. If they are perfectly vertical on both ends, the board is most likely free of any substantial amount of runout. If the lines are nice & vertical on one end & lean one way or the other on the opposite end, you have some degree of runout. If the lines are off vertical at both ends, it gets a bit more complicated... When you are checking for this, hold the board in both hands hand & flip it end for end only. Don't turn the board... If the lines appear as a "back slash" or a "forward slash" on both ends, you have some runout. If the line angles appear to reverse from end to end, your board is off quarter to some degree, but (if the angle is the same on both ends) the runout is minimal. Extreme runout, like in the spruce picture above is easy to see. The method I described will detect very minor runout easily. This is a quick & easy method to use if you are grading tops or digging through a stack of wood to pick out the ones you want to buy. |

|

| Author: | BlackHeart [ Fri Sep 07, 2007 4:32 am ] |

| Post subject: | |

Im not getting this. I just cut some braces and I made sure the dark streak of grain ran all the way through the brace, and that the ring lines in the top ran down the middle. Are you saying there could still be runout???

|

|

| Author: | erikbojerik [ Fri Sep 07, 2007 5:32 am ] |

| Post subject: | |

OK, so I've seen runout quantified by measuring the horizontal distance (along the grain) that the grain takes to go from one face to the opposite face; then this distance is normalized to the thickness of the billet. i.e. like 18" per 1/8" thickess means that on a 1/8" thick piece, it takes 18" (along the grain) for the grain to run from the inner face to the outer face. Get my drift? Using that as a metric, what do you suppose is the worst runout acceptable for a top? And if you're even better informed....how would this metric vary among the different grades of soundboard lumber? |

|

| Author: | SimonF [ Fri Sep 07, 2007 8:59 am ] |

| Post subject: | |

Blackheart, yes, you could still have runout. Beveling the outer edge of a top (or bracing, etc...) will not reveal any information on whether the top has runout. The best way to prove this to yourself is to take a piece of spruce and give it terrible runout and then bevel the edge. As long as the grain runs parallel to the bevel, the grain lines will run straight down the board. DanielM gave a very good suggestion. However, if you spare some material, I would just cut off a small piece lengthwise and split the grain. You should be able to see very clearly whether the piece has runout or not and there would be no question about its certainty. Of course, runout can vary throughout a piece as wide as what we use for a guitar top. Erik, I have no idea where to draw the line when it comes to severe runout. I do know that some people use the flamed redwood for tops and that is a case of severe runout. I personally would not feel comfortable using such a top unless it was a double top or left very thick. Maybe someone with a bit more experience will chime in here and shed some light on that issue. However, here is an interesting link you might want to check out. It shows how runout affects the continuity of a bookmatched set. Link |

|

| Author: | erikbojerik [ Fri Sep 07, 2007 12:12 pm ] |

| Post subject: | |

Thanks for the link Simon. I recall seeing that photo before, but I'd forgotten that the runout metrics were scribbled in the corner like that (just the inverse of the one I recalled). So where would you grading guys draw your boundaries in that photo?? |

|

| Author: | Daniel M [ Fri Sep 07, 2007 12:24 pm ] |

| Post subject: | |

Each of us will find his / her own limits for acceptable runout limits. Speaking personally, if I can clearly see a colour shift in the rough cut top, I would prefer not to use it. Runout can negatively affect cross grain stiffness. I will reject a top if it feels too floppy. That being said, each piece of wood has to be considered on it's own merits... & on how it will be used. I have seen many fine guitars which display clear evidence of top runout... I have no idea whether they would have sounded better or lasted longer with a "better" grade of top. If you are going to test for runout by splitting a piece of wood, make sure you set your splitting knife as close to the exact centre as possible. If you are off centre, you can get a false runout indication... especially if the piece being tested is fairly thin. |

|

| Author: | Daniel M [ Fri Sep 07, 2007 12:29 pm ] |

| Post subject: | |

Each of us will find his / her own limits for acceptable runout limits. Speaking personally, if I can clearly see a colour shift in the rough cut top, I would prefer not to use it. Runout can negatively affect cross grain stiffness. I will reject a top if it feels too floppy. That being said, each piece of wood has to be considered on it's own merits... & on how it will be used. I have seen many fine guitars which display clear evidence of top runout... I have no idea whether they would have sounded better or lasted longer with a "better" grade of top. If you are going to test for runout by splitting a piece of wood, make sure you set your splitting knife as close to the exact centre as possible. If you are off centre, you can get a false runout indication... especially if the piece being tested is fairly thin. |

|

| Author: | Daniel M [ Fri Sep 07, 2007 12:31 pm ] |

| Post subject: | |

Sorry guys... I must have hit the button twice! |

|

| Author: | fryovanni [ Sat Sep 08, 2007 3:17 am ] |

| Post subject: | |

That is what I found in this topic-topic I couldn't detect runnout that I knew was present(referencing the split face. The bevel method shows little more than how the visable grain runs through the board. Looking at the side of a board, the visual clues reflect visual grain that runs out at the edge(which is appearant from looking at the top face). Splitting or looking at the bookmatch are the two clues I look to. Since I cut my own tops from split wood, it is not really something I have to question. Peace,Rich |

|

| Page 1 of 1 | All times are UTC - 5 hours |

| Powered by phpBB® Forum Software © phpBB Group http://www.phpbb.com/ |

|