I just use separate bits of hardboard, I've never had a bar slip yet, nice thing is these fit every size guitar I make! I can see the benefits of a dedicated caul though.

Colin

| Official Luthiers Forum! http://w-ww.luthiersforum.com/forum/ |

|

| Cauls for Closing the Box http://w-ww.luthiersforum.com/forum/viewtopic.php?f=10102&t=13545 |

Page 1 of 1 |

| Author: | JJ Donohue [ Thu Sep 06, 2007 11:55 pm ] |

| Post subject: | |

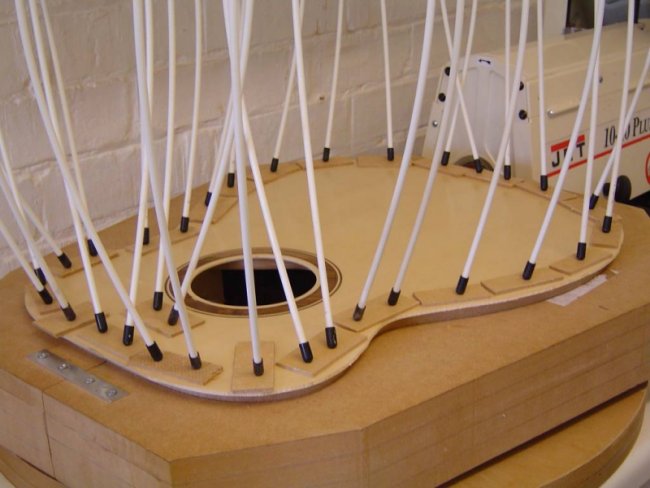

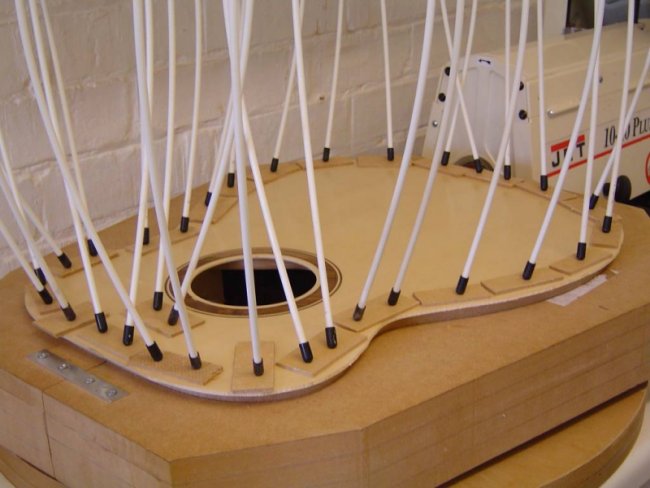

I use a similar caul setup when gluing a top with HHG. I use only about 16 - 20 gobars however. I also have a "dimple" drilled at each location on the caul where a gobar is positioned. This has prevented any gobar slippage. I've used this method on 6 guitars so far. |

|

| Author: | Colin S [ Fri Sep 07, 2007 12:20 am ] |

| Post subject: | |

I just use separate bits of hardboard, I've never had a bar slip yet, nice thing is these fit every size guitar I make! I can see the benefits of a dedicated caul though.

Colin |

|

| Author: | dsharp [ Fri Sep 07, 2007 12:43 am ] |

| Post subject: | |

I use a similar caul with a groove routed in the middle to accept the go bars. |

|

| Author: | burbank [ Fri Sep 07, 2007 12:56 am ] |

| Post subject: | |

I use a scrap top that I got in a Martin reject lot. It's floppy like piece of wet cardboard, so I had no intention of using it. Just one piece, very fast to use and protects the whole top or back in case of a slip.

|

|

| Author: | Arnt Rian [ Fri Sep 07, 2007 1:10 am ] |

| Post subject: | |

I have a caul like that too. Mine is made out of 5mm plywood and I glued a layer of cork to the side that goes against the guitar top. |

|

| Author: | Bruce Dickey [ Fri Sep 07, 2007 1:13 am ] |

| Post subject: | |

I do the same as Colin, just scraps of hardwood in my case. Of course, not everyone uses gobar decks to close their boxes. Some folks use cam clamps. Pat, I really like the OLD top idea, that does protect the whole top nicely!! |

|

| Author: | Michael Dale Payne [ Fri Sep 07, 2007 1:59 am ] |

| Post subject: | |

I too use pressed hard board cut to just over shape with the center open to allow the dome to rise through as shown in Todd's picture. But I don't use near that many go-bars  More like the amount Colin shows More like the amount Colin shows

|

|

| Author: | KenH [ Fri Sep 07, 2007 1:59 am ] |

| Post subject: | |

As Bruce mentions, My cam clamps have cork on each face to protect whatever I am clamping. no need for cauls. This is a picture of a back being glued on, but I do the tops the same way.

|

|

| Author: | LuthierSupplier [ Fri Sep 07, 2007 2:23 am ] |

| Post subject: | |

I do the same as you Todd, works great! Putting some carpet on the top of the deck helps the top bars from slipping. Nice pic! Tracy |

|

| Author: | stan thomison [ Fri Sep 07, 2007 3:02 am ] |

| Post subject: | |

radius dish cut to shape, back and top same time in a press. |

|

| Author: | Mattia Valente [ Fri Sep 07, 2007 4:39 am ] |

| Post subject: | |

Same setup as Todd's, only 1/8" tempered hardboard, 'rough' side down. Only I didn't cut it so neatly, as I eyeballed it with a jigsaw. Cheap and functional. |

|

| Author: | old man [ Fri Sep 07, 2007 5:13 am ] |

| Post subject: | |

Mine is just like Todd's also, even use that many go bars. If I had as many cam clamps as Ken, though, I'd try his way cause it looks really cool. Ron |

|

| Author: | JimWomack [ Tue Sep 11, 2007 12:20 am ] |

| Post subject: | |

When I made the jump from PVA to HHG, I knew that closing the box was going to be more challenging. Turns out I was right. I originally used a slightly oversized caul with screws ala Kincaid... OK for PVA but too slow for HHG. I then went with the go-bar deck. Still too slow for me, guess I'm just go-bar challenged. I settled on a series of wooden cauls using oversized eyebolts. The clamping edge is lined with 1/2 weather stripping, protecting the wood and thick enough to allow the caul to clear the top/bottom arch. Notice the thin masking tape collar which prevents the eyebolts from falling out of the caul... Important when you're tring to work quickly.  I start out by clamping the wasit first. Once it is tightened, the top/back is pretty much locked into place. The holes in the cauls for the eyebolts are oversized which allows the caul to follow the taper of the sides. The stop blocks are positioned so that only a turn or two of the eyebolt is needed for good clamping pressure.  I then alternate the cauls, working my way toward either end.  I can get all the clamps in place in less than a minute giving me plenty of time to clean up the squeeze-out. It's not as elegant as the go-bar deck but it does work well for me... quick and consistent. |

|

| Author: | redennis3 [ Tue Sep 11, 2007 12:43 am ] |

| Post subject: | |

I just use a radius dish on both sides and clamp it all together like a big sandwitch......................mmmm I'm gettin hungry. Red |

|

| Author: | letseatpaste [ Tue Sep 11, 2007 12:54 am ] |

| Post subject: | |

I did as Red did on my last one, guitar sandwich. It worked out real slick. I can see this being a problem if you flatten the upper bout of the top and the rest is domed. Mine's a true flat top, though, so just a flat board worked fine. I did use corkboard to help distribute the pressure around the edges.

|

|

| Author: | Bill Greene [ Tue Sep 11, 2007 2:29 am ] |

| Post subject: | |

[QUOTE=redennis3] I just use a radius dish on both sides and clamp it all together like a big sandwitch......................mmmm I'm gettin hungry. Red [/QUOTE]Ditto. |

|

| Page 1 of 1 | All times are UTC - 5 hours |

| Powered by phpBB® Forum Software © phpBB Group http://www.phpbb.com/ |

|