this is like the third time ive written this because i couldnt figure out how to resize my pictures to be less than 200KB. finally got it. a man i work with always says, "heath, there's a learning curve to everything." i think hes right. in fact, i know he is. anyways, back to the matter at hand.

ok, so i finished up my guitar mold and side bender sometime last week and before i went to town bending my actual guitar sides (peruvian walnut), i thought id have a few practice rounds with some quarter sawn red oak (home depot). to my amazement (and delight), i was able to thickness two 36"x4"x1/4" boards to .085" on my thickness planer. i was fully expecting a splintery explosion, but everything worked out just peachy.

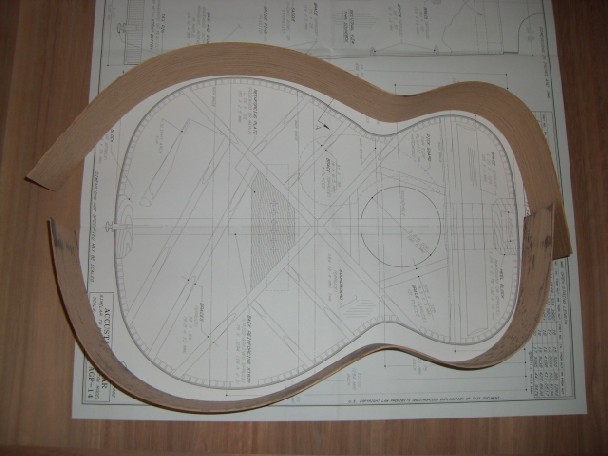

heres a pic of my bender. six inches wide. solid MDF. i used one caul at the waist, two at the upper bout, and two at the lower bout.

i compensated the form only with the thickness of the wood and one spring steel slat (.015"). my "sandwich" was blanket/slat/wood/slat. fisrt attempt wood was misted with tap water and wrapped in parchment paper. stained the wood and rusted the heck out of my steel slats. second attempt was just wrapped in foil, no water. i studied hesh's side bending tutorial and then went to town. both sides were cooked twice at (?) temperature. im not sure how much i trust the little digital thermomter that came with the side bender. i dont think it ever read 300 degrees, but was on for ten minutes or more. the second side i let sit over night and i think it was worse than the first. so here is my first attempt at bending. im sure youll understand why i think i stink at bending. what in the world went wrong?

But I think the rational is the same even with just a blanket.

But I think the rational is the same even with just a blanket.

). it was cool outside, but definitely not cold. i did hold the wood together with spring clamps. with the blanket being on for such a long period of time, and still not transfering enough heat, is it possible there is something wrong with the blanket? i dont know. i think ill give it another go tonight. good fun.

). it was cool outside, but definitely not cold. i did hold the wood together with spring clamps. with the blanket being on for such a long period of time, and still not transfering enough heat, is it possible there is something wrong with the blanket? i dont know. i think ill give it another go tonight. good fun.