Todd, you yet again give another excellent tutorial.

Thanks so much for a great method on making some of the most important aspects of lutherie, the molds that make th guitar take shape.

| Official Luthiers Forum! http://w-ww.luthiersforum.com/forum/ |

|

| Forms for Blanket Bending - One Method http://w-ww.luthiersforum.com/forum/viewtopic.php?f=10102&t=14200 |

Page 1 of 1 |

| Author: | RobE [ Tue Oct 23, 2007 7:43 am ] |

| Post subject: | |

Todd, you yet again give another excellent tutorial.

Thanks so much for a great method on making some of the most important aspects of lutherie, the molds that make th guitar take shape. |

|

| Author: | letseatpaste [ Tue Oct 23, 2007 7:54 am ] |

| Post subject: | |

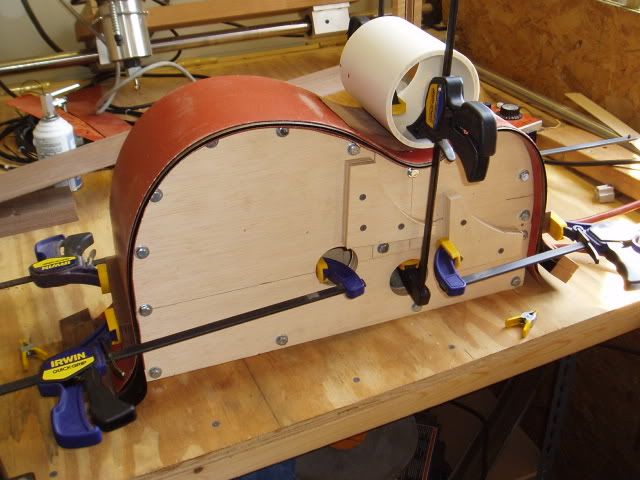

Another benefit of the solid bending mold is that you could use it for laminating bent sides. I'm planning on eventually trying that when I get my Swap Meet vacuum pump set up and operational. |

|

| Author: | Mattia Valente [ Tue Oct 23, 2007 12:01 pm ] |

| Post subject: | |

Pretty much the exact way I did my last one, although I left a 'foot' in the waist area because I'm 90% done making a doolin-style bender, couldn't find destaco style clamps for the waist shoe, so I'm using hooks screwed into the forms themselves and threaded eyebolts. My first form was also more or less like this, and it worked an aboslute charm. |

|

| Author: | Brock Poling [ Tue Oct 23, 2007 12:32 pm ] |

| Post subject: | |

One thing I do.. (and I would highly recommend this if you are going to laminate your sides) is to undersize the mold by .10". With 1 side at normal springback you can kind of fudge it to make it work, but once you laminate 2 sides they stay put in a very serious way. Having the bends and lamination molds undersized by the thickness of the sides gives you a very comfortable fit without a lot of pressure from the spreaders. This is a great tutorial. Thanks. I should have followed your lead. My lam mold weighs a ton, and my bending mold is not quite solid. I did 2 solid pieces in the center, and one on each side. Thanks! |

|

| Author: | James Orr [ Tue Oct 23, 2007 3:37 pm ] |

| Post subject: | |

I like that a lot, especially the tip about the nylon bushing. One question re: using the vac. When I veneered drum shells, I needed to use construction styrofoam insulation (the thick pink stuff) because there was no air. My vac still bent the shells out of round. Are you sure your mold with the big air space below will hold up in a vacuum bag without imploding? |

|

| Author: | Mattia Valente [ Tue Oct 23, 2007 4:32 pm ] |

| Post subject: | |

Todd: I'll take a few pics when I find the time, although Mike describes it all very well on his website: http://www.doolinguitars.com/articles/bender/ I made a couple of changes to allow the use of regular clamps instead of ones screwed to the form, and I still need to make the swing arm bit and test-run it. |

|

| Author: | erikbojerik [ Wed Oct 24, 2007 1:09 am ] |

| Post subject: | |

Thanks Todd! Great tutorial, both this and the mold one. Looks like you might be able to get a few more of the bending form lams out of the inside offcuts of the mold sections...if you slice them out on the bandsaw after making the outside cut with the jigsaw. Unless I'm missing something. On the one bending form I've made (D-sized two outside ply sections separated by aluminum metal tubing), I made the cutaway section removable so that you could swap out a regular shoulder, a Venetian cutaway, or a Florentine cutaway all on the same base form. So one bending form will allow you to bend both sides of an instrument with a cutaway.   |

|

| Page 1 of 1 | All times are UTC - 5 hours |

| Powered by phpBB® Forum Software © phpBB Group http://www.phpbb.com/ |

|