Cheers

| Official Luthiers Forum! http://w-ww.luthiersforum.com/forum/ |

|

| Downspiral flush trimming bits http://w-ww.luthiersforum.com/forum/viewtopic.php?f=10102&t=14498 |

Page 1 of 1 |

| Author: | Andy Matthews [ Mon Nov 12, 2007 9:20 pm ] |

| Post subject: | |

Do they exist? If so, who stocks em? Cheers |

|

| Author: | Andy Matthews [ Mon Nov 12, 2007 11:07 pm ] |

| Post subject: | |

Cheers

|

|

| Author: | Andy Matthews [ Mon Nov 12, 2007 11:26 pm ] |

| Post subject: | |

[QUOTE=ToddStock] Might check their sites to see if they have a UK rep - might save you some time and money on shipping.[/QUOTE] Indeed. The email has been sent. Thanks again |

|

| Author: | Hesh [ Mon Nov 12, 2007 11:53 pm ] |

| Post subject: | |

This is interesting to me and I have a couple of questions if I may please. I use a conventional flush cut bit in a laminate trimmer to take off the over hang of the top and back after they are glued. The resulting cut is never flush and leaves something around a 1/16" over hang. Before I started using a Flieshman/Williams jig the bearing did not ride flat on the side either and I would get an indentation from the edge of the bearing in softer woods. The F/W jig cured this but I am still left with the slight over hang. I understand that the advantage of the spiral down cut bit is less potential for tear out and a cleaner cut. But the cutting area of the bit, spiral down cut, has a smaller diameter than the conventional bit. If my over hang prior to trimming is greater than 1/4", and sometimes it is, the bit will be cutting on three sides and not just two as the conventional bit will. If I used a spiral down cut but does it become critical that the pre-cut over hang be less than the width of the bit? And... how much less? Also, in anyone's experience will these bits cut closer to the actual side of the guitar and leave me with less of an over hang, or no over hang then the conventional bits? Thanks. |

|

| Author: | grumpy [ Tue Nov 13, 2007 2:48 am ] |

| Post subject: | |

Hesh, too many questions... <g> But... I use the "Guide Point" Rotozip bits to cut the top and back flush t the sides. I keep one of these(1/8") bits in a router table just for this. The important part is to leave more than 1/4" of wood overhanging. In fact, today, I leave the whole plate and simply trim it once it's glued to the ribs. Trims dead flush to the sides.... Since it has no bearing, but instead, a polished, smooth tip, it's important that you move quickly around, and never stop. Takes a bit of confidence, but it works like a charm. I touch the spinning tip with a wax stick or candle just before going 'round, but it's not absolutely necessary. And they're dirt cheap, so give 'em a shot. They also make a 1/4" one, but it didn't work as well as the 1/8" ones do for trimming plates. |

|

| Author: | grumpy [ Tue Nov 13, 2007 2:54 am ] |

| Post subject: | |

Oh, and if you try the above, make a small block of the height that you taper your sides(IE: if your taper is 1/2" from tail to neck block, make a 1/2" block, if it's 3/4", make a 3/4" block, etc...) and tape that to the back, near the neck block, so the sides will be perpendicular to the router table. Otherwise, no biggie, but it won't be cut perfectly flush. In my case, i don't bother with the blocks anymore, as the next step after trimming is to route a shallow "binding" cut, which takes care of any overhang, anyhow. I make this shallow cut as a depth guide while sanding the sides flat, before routing for bindings. |

|

| Author: | Bill Greene [ Tue Nov 13, 2007 3:06 am ] |

| Post subject: | |

[QUOTE=grumpy] I make this shallow cut as a depth guide while sanding the sides flat, before routing for bindings.[/QUOTE] Ooooo, that's a good idea.

|

|

| Author: | Kent Chasson [ Tue Nov 13, 2007 3:17 am ] |

| Post subject: | |

If I used a spiral down cut but does it become critical that the pre-cut over hang be less than the width of the bit? Spiral bits are solid carbide and very brittle, particularly ones that are less than 1/4". The less bite you take with them, the better. And don't go too fast. They work great for binding channels though but I like the 1/2" ones. If you're using a jig that holds the router parallel to the sides, I'm not sure why the bit should leave 1/16" overhang. |

|

| Author: | Hesh [ Tue Nov 13, 2007 3:39 am ] |

| Post subject: | |

Thanks Mario I understood your method very well and it sounds like a way better way to go. So I am off to the Borg this afternoon to get some Rotozip guide point 1/8" bits. Tell me though what size is the part of the bit that is chucked in the router/laminate trimmer - 1/4" I hope? They should work fine in the F/W jig as long as I keep moving as you indicated and I have more than 1/4" of overhang. And as Bill said the shallow binding channel sounds like a best practice to me too. This takes the edges of the plates completely out of play when sanding the sides! It also sounds like there is the additional benefit of less to cut when cutting the binding channels since this has now been done in a couple of passes. Excellent!!!!    Kent all good points and thanks for reminding me about the frailness of the spiral down cut bits! |

|

| Author: | grumpy [ Tue Nov 13, 2007 4:01 am ] |

| Post subject: | |

No, you'll need to get a 1/4" to 1/8" adapter. What's a F/W jig, pray tell? |

|

| Author: | WaddyThomson [ Tue Nov 13, 2007 4:21 am ] |

| Post subject: | |

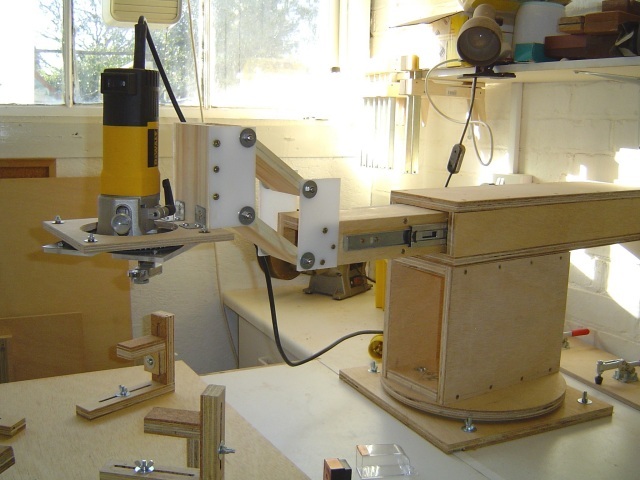

Fleishman/Williams binding jig. One of these.  |

|

| Author: | Hesh [ Tue Nov 13, 2007 4:26 am ] |

| Post subject: | |

Sorry Mario - Waddy thanks for answering. OK a 1/4" to 1/8" adapter just got added to the list here. Many thanks Mario. |

|

| Author: | Howard Klepper [ Tue Nov 13, 2007 6:11 am ] |

| Post subject: | |

I rough off the overhang with a 4" drawknife. Fast (can be too fast if you aren't careful to always cut downhill) and lots of satisfying tactile feedback. Won't get into the center of an inside curve completely, but a good rasp takes care of those spots. I don't bother making the top and back flush before routing for purfling and binding. What matters is a smooth side surface for the bearing on the binding router bit, right? You can sand that surface smooth without a flush top or back. |

|

| Author: | Howard Klepper [ Tue Nov 13, 2007 6:13 am ] |

| Post subject: | |

Oh, yeah, I use a plane on the end grain areas, where the drawknife gets bogged down. And have learned from hard experience to tape my fingers on the planing hand. |

|

| Author: | grumpy [ Tue Nov 13, 2007 7:59 am ] |

| Post subject: | |

I used to also use a knife and plane to trim off the excess. Only took one slip and a deep gouge in the side of a mahogany guitar body (Read: can't be hidden) to convince me to do otherwise... What matters is a smooth side surface for the bearing on the binding router bit, right? yes and no. Yes, it's basically all that's needed, but no, not the safest. When a router bit encounters unsupported wood, like it does if we leave some overhang, it's more likely to tear out a chunk than it would if it is biting into wood(top or back) that is solidly glued to another surface(sides). |

|

| Page 1 of 1 | All times are UTC - 5 hours |

| Powered by phpBB® Forum Software © phpBB Group http://www.phpbb.com/ |

|