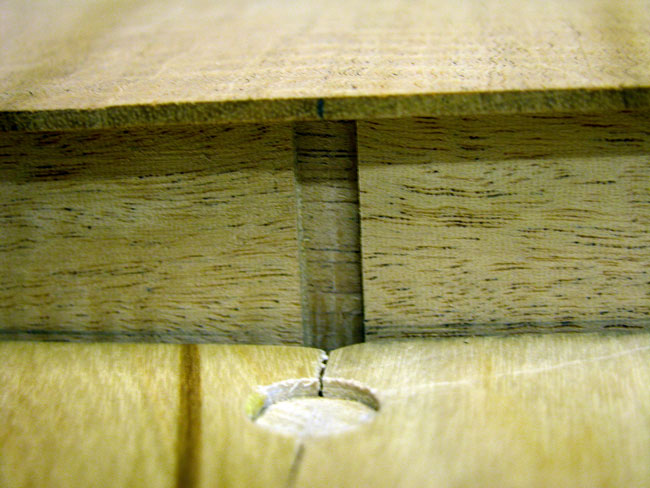

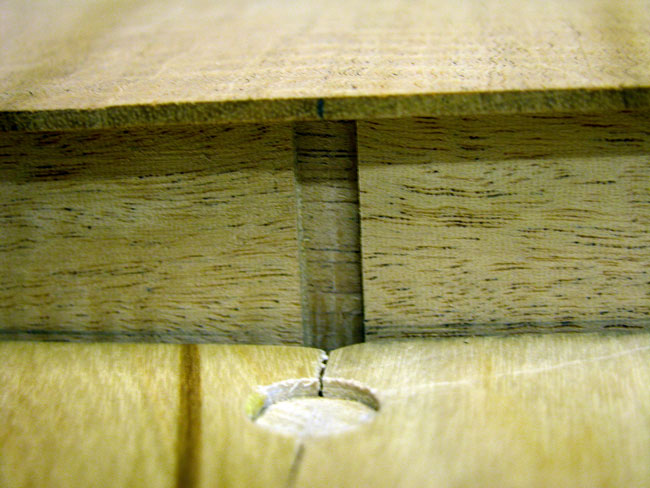

Well something hit me when I reread this thread so I went and checked my shop. Looks like I lied because I forgot to glue in the end graft prior to putting the back on this time.......

So I guess that I do it either way before or after now......

| Official Luthiers Forum! http://w-ww.luthiersforum.com/forum/ |

|

| When do you put your End graft in? http://w-ww.luthiersforum.com/forum/viewtopic.php?f=10102&t=14595 |

Page 1 of 2 |

| Author: | Blain [ Mon Nov 19, 2007 4:21 pm ] |

| Post subject: | |

I'm wondering when everyone puts an end graft into their guitars, before closing the box or after? Thanks in advance for your comments. |

|

| Author: | burbank [ Mon Nov 19, 2007 4:23 pm ] |

| Post subject: | |

After, on all of the three that I've done. |

|

| Author: | Kevin Gallagher [ Mon Nov 19, 2007 4:25 pm ] |

| Post subject: | |

Blain, I put my tail wedge in right after the neck and rear blocks are installed to the bent sides to form the rim. This way, it allows me to work with the rim outside of the mold and to clamp the rim onto a corner of my bench to cut the cavity for it. Regards, Kevin Gallagher/Omega Guitars |

|

| Author: | Hesh [ Mon Nov 19, 2007 5:06 pm ] |

| Post subject: | |

I do what Kevin does. |

|

| Author: | Dave Anderson [ Mon Nov 19, 2007 5:25 pm ] |

| Post subject: | |

I do mine after the box is closed. |

|

| Author: | Mattia Valente [ Mon Nov 19, 2007 5:33 pm ] |

| Post subject: | |

After the box is closed. The reason's simple: once the sides are bent, they stay in the mold, no moving, until I glue the top and back on. |

|

| Author: | KenH [ Mon Nov 19, 2007 5:36 pm ] |

| Post subject: | |

I have done it 2 ways: after the box is closed and before the binding goes on and after the binding is on. When doing it after the binding is on, you have to use a router to cut out the pocket for the wedge. |

|

| Author: | Blain [ Mon Nov 19, 2007 6:23 pm ] |

| Post subject: | |

Thank you all. I did my #1 as Kevin and Hesh do because it just made sense to me. Now that I'm at that point on #2 I thought I would see what everyone else is doing because I had seen plenty of tutorials here on End Grafts that put them in after the box was closed up. |

|

| Author: | Howard Klepper [ Mon Nov 19, 2007 7:30 pm ] |

| Post subject: | |

I do it after gluing the head and tail blocks to the rim, before the top and back go on. At that point, I can clamp the rim set in a gunstock/patternmakers vise (what StewMac calls a guitar repair vise), with the vise jaws on the tailblock and the butt of the guitar up. The vise sticks out from my bench so the rims can clear the bench. I cut the dado with backsaw and chisel--old fashioned, but satisfying and not at all hard to do. I can easily clamp the graft down while the glue dries, since I can puyt a clamp around the tailblock. I don't build in molds, so taking it out is not an issue. BTW, Bruce Sexauer puts the graft in after binding the guitar. Lots of ways to skin the cat. |

|

| Author: | Colin S [ Mon Nov 19, 2007 7:31 pm ] |

| Post subject: | |

After the binding channel is cut, but before binding. Colin |

|

| Author: | Andy Matthews [ Mon Nov 19, 2007 9:21 pm ] |

| Post subject: | |

[QUOTE=Colin S] After the binding channel is cut, but before binding. Colin[/QUOTE] +1 |

|

| Author: | Arnt Rian [ Mon Nov 19, 2007 11:43 pm ] |

| Post subject: | |

After the body is built, before the binding chanel is cut. That way I can cut the binding channel across the end graft at the same time as I cut the rest of it. |

|

| Author: | tippie53 [ Tue Nov 20, 2007 12:47 am ] |

| Post subject: | |

The best time for me is when the blocks are glued in. I can clamp straight edges to the tail block. Doing them after the binding cut is risky . If you chip out at this point you now have repair work that may shop. Find the technique you like . john hall |

|

| Author: | Mike Mahar [ Tue Nov 20, 2007 1:07 am ] |

| Post subject: | |

I install it after the box is glued up and the instrument is out of the mold. If I'm installing side purfling, I lightly tack a piece of purfling slightly wider than the wedge to the top and bottom of the guitar. When I cut binding channel, the router rides up on the piece of purfling and makes the binding channel shallower by the width of the purfling. I make the purfling piece a little wider than the wedge and cut ramps on it so the binding cutter rides up smoothly. I then only have a little cleanup to do with a chisel. |

|

| Author: | stan thomison [ Tue Nov 20, 2007 1:41 am ] |

| Post subject: | |

next step after gluing rims to blocks. same reason as howard. |

|

| Author: | Hesh [ Tue Nov 20, 2007 1:48 am ] |

| Post subject: | |

Well something hit me when I reread this thread so I went and checked my shop. Looks like I lied because I forgot to glue in the end graft prior to putting the back on this time.......    So I guess that I do it either way before or after now......  |

|

| Author: | letseatpaste [ Tue Nov 20, 2007 1:55 am ] |

| Post subject: | |

[QUOTE=Mike Mahar] I install it after the box is glued up and the instrument is out of the mold. If I'm installing side purfling, I lightly tack a piece of purfling slightly wider than the wedge to the top and bottom of the guitar. When I cut binding channel, the router rides up on the piece of purfling and makes the binding channel shallower by the width of the purfling. I make the purfling piece a little wider than the wedge and cut ramps on it so the binding cutter rides up smoothly. I then only have a little cleanup to do with a chisel. [/QUOTE] That's very clever... Thanks for mentioning that. |

|

| Author: | LanceK [ Tue Nov 20, 2007 1:56 am ] |

| Post subject: | |

[QUOTE=Colin S] After the binding channel is cut, but before binding. Colin[/QUOTE] +2 I have a nice jig that clamps to the closed up body and allows me zip right through the process. It takes me longer to get the jig off the shelve than it does to cut the channel. |

|

| Author: | DP LaPlante [ Tue Nov 20, 2007 2:20 am ] |

| Post subject: | |

I've pretty much done it in all the various ways described. It depends, if it is a steel string dovetail guitar with body constructed separately from the neck the graft goes in at the rim stage before top and back and trimmed in place when routed. If it is a classical guitar which is assembled on a solera (work board) I will put it in once the neck/top/side assembly is together but before the back is on this facilitates the alignment of the back strip which usually matches the endpiece on my guitars. The exception is something like a style 45 which has a complex inlaid and mitered endpiece. In this case a tapered slug (usually maple) is fitted without glue at the rim stage. This provides a smooth surface for the cutter bearing to ride on to cut the binding and purfling channels. The slug is then removed and the various strips are installed and mitered to intersect with the side purflings.

|

|

| Author: | grumpy [ Tue Nov 20, 2007 2:57 am ] |

| Post subject: | |

I do mine after the top and back are glued, but before cutting the bindings channels. Reasons being, if I installed it before gluing the plates, and the plates moved a bit, now the end graft isn't centered perfectly, which is quite noticeable at the back junction, where the graft meets the backstrip. Been there..... changed my ways. Second, if we cut the binding channels first, then we risk a blowout when we rout(assuming we use routers) the end graft channel, because it exits in short grain at the binding channel. By cutting the end graft channel first, if there's a little blowout, it's of no consequence, because the binding channel will be cut next.. Also, by routing te binding channel -through- the glued-in end graft itself, we have a perfectly seamless joint. Only time this isn't so is when we wish to do fully mitered purflings(45 style, for example) |

|

| Author: | TonyKarol [ Tue Nov 20, 2007 3:33 am ] |

| Post subject: | |

After the binding slot if I am mitring the purf lines, before if its a lap joint. Using a downcut spiral, the blowout Mario talks about above is pretty much nonexistant for me. |

|

| Author: | Colin S [ Tue Nov 20, 2007 3:41 am ] |

| Post subject: | |

This is a job that I've never even considered using a router for, steel rule, marking knife and chisel, it's done before I could get the bit in the router and set up a jig. OK if your doing a lot of guitars like Mario then router set up is probably justified but for the 3 or 4 a year builder? Colin |

|

| Author: | BruceHerrmann [ Tue Nov 20, 2007 4:06 am ] |

| Post subject: | |

After reading this thread I'm going to re-think the way I do the end graft- I always mark my center lines on the tops and bottoms of the end and neck blocks but don't always line up the sides exactly on the line center line of the tail block as it will be covered by the end graft. I've taken the rims out of the mold, set up straight edges and saw cut the outside lines and then chiseled out the area for the graft. All this has been described but I think in my case this leaves the chance for the graft to be slightly off of the centerline of the top and back joints, not good. Seems like there is logic in gluing the top and back on, and before binding, cut that slot, insuring that the end plate is perfectly in line with the top and back centerlines. I'm sure most of you guys have that covered but for me as an amateur, it's not a given! Thanks for the good ideas. |

|

| Author: | Steve Kinnaird [ Tue Nov 20, 2007 5:28 am ] |

| Post subject: | |

[QUOTE=grumpy] I do mine after the top and back are glued, but before cutting the bindings channels. Reasons being, if I installed it before gluing the plates, and the plates moved a bit, now the end graft isn't centered perfectly, which is quite noticeable at the back junction, where the graft meets the backstrip. Been there..... changed my ways.Second, if we cut the binding channels first, then we risk a blowout when we rout(assuming we use routers) the end graft channel, because it exits in short grain at the binding channel. By cutting the end graft channel first, if there's a little blowout, it's of no consequence, because the binding channel will be cut next.. Also, by routing te binding channel -through- the glued-in end graft itself, we have a perfectly seamless joint. Only time this isn't so is when we wish to do fully mitered purflings(45 style, for example)[/QUOTE] +1 Steve |

|

| Page 1 of 2 | All times are UTC - 5 hours |

| Powered by phpBB® Forum Software © phpBB Group http://www.phpbb.com/ |

|