For years I depended on the use of one particular jointer that I had access to for excellent results. Unfortunately that machine was destroyed in an accident during a move and for several years getting good results in joining tops was a problem.

Recently at the Romanillos course in Spain Jose' illustrated the proper use of the shooting board and plane combination as well as the little tricks of pressure and release neccessary to producing a good join.

Upon my return 10 bucks worth of material to make the board and the purchase of an old jointing plane (the big long one made by Stanley for Montgomery Ward) for 50 bucks on EBAY means that I've solved this particular problem.

I think it is an excellent solution for the small builder. Yes, I have a small jointer but to match the quality of the shooting board approach you will need to make a substantial investment in a quality machine.

|

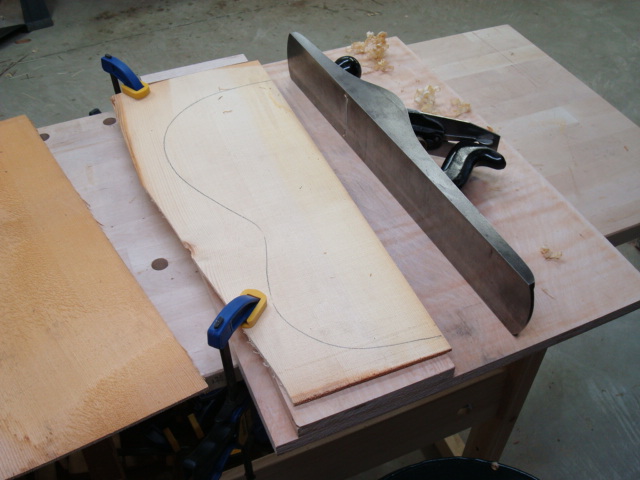

This pic should be self explanatory.

This pic should be self explanatory.