I have been wanting to try implementing an armrest, but haven't had a really good idea on what I wanted it to look like or how to do it. Finally I decided to just take some time and fiddle with some scrap until I figured it out. Here's the result of that exercise; I hope someone finds it useful.

I have previously resisted building an armrest bevel because I couldn't think of a good way to bind the bevel on the side without a lot of potentially disastrous hand work. It finally came to me that I could bend some wood that would follow the curve of the sides and use that as a template for a router. I could use a separate template to bind the top.

First off, to make the top template I took a piece of MDF shaped to my OM shape and cut in a comfortable bevel with a pattern-maker's rasp. I measured the depth of the bevel at a few spots to define the side profile:

Next I took the top template to the spindle sander to finalize the top profile. Safety tip: use a mask when sanding MDF, as sanding releases formaldehyde which is not good for the lungs!

Finally here is the template next to a mold I use to laminate sides:

To make the side template I resawed some mahogany into three pieces about 1/8" thick. Using the depth measurements from the top template, I drew on the side profile:

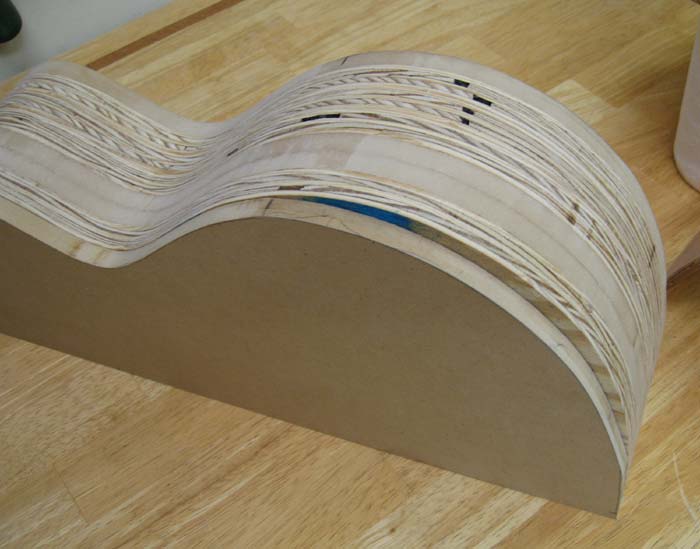

At the bandsaw, I got close to the edge of the profile but left a little to remove after bending and gluing. Next I bent the slices together in a side bender and finally glued them up as a bent lamination using a vacuum bag over my side mold. This is pretty much the same setup I now use for laminating sides:

After the glue up I finished carving the profile with a rasp and some sandpaper. Here is the finished template on the mold:

Next up, the lining. I took the max depth of the bevel and added 3/16" to get the thickness I would need, then milled a piece of mahogany to that thickness and drew on the inside of the lining (where the lining will meet the sides) using my side mold:

Using the top bevel template as a guide and adding another 3/16", I did the same for where the lining will meet the top, then cut it out on the bandsaw and used the spindle sander to get the final shape and hog out a bevel which will show on the inside of the guitar:

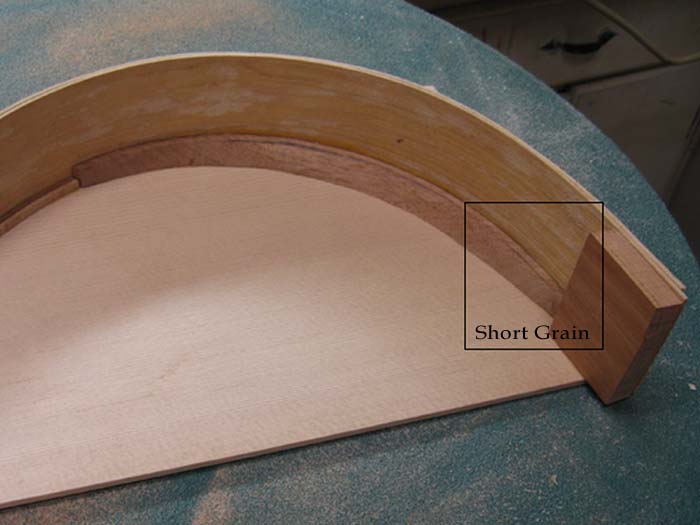

I bent and glued up a couple of pieces of scrap and attached them to some scrap spruce for this exercise and glued in the bevel lining just like any other lining. I noticed that there's no way to avoid short grain if you cut out the lining from a solid piece of wood. For a real guitar I will probably use a bentwood lamination for the lining so that all glue contact is long grain to long grain:

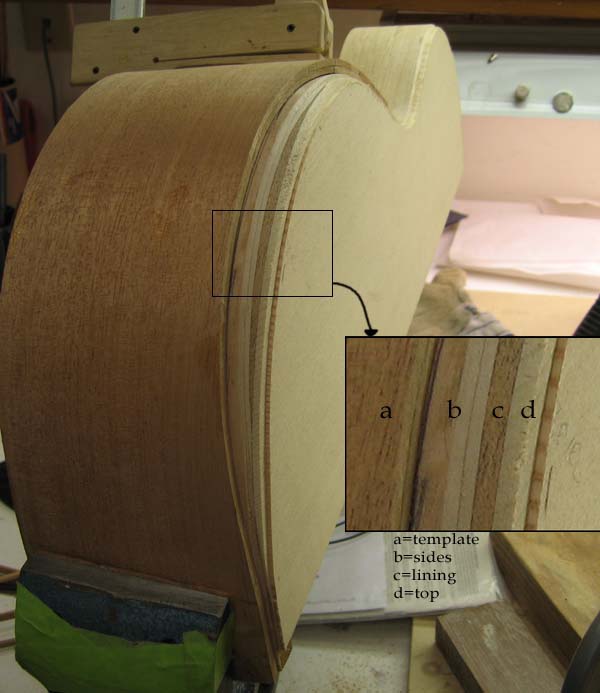

Next up, the fun part: carving the bevel. Using the templates I marked the bevel and used my #49 rasp to carve it out. I then clamped the templates on (for a closed guitar I would attach with double-sided tape) and cut the purfling channels with my dremmel:

Finally I cut binding/purfling channels where the bevel meets the top, glued in the bindings and purflings, and carved and sanded everything to final shape. For kicks I cut a channel by hand to connect the bottom purfling to the top purfling to see what kind of line that would create:

For a real guitar I might not want the spruce and side material to show, so I would carve the bevel a little deep and add a veneer overlay before cutting the purfling channels. I would have to be very careful when carving to make sure the overlay lined up with the purfling lines. I began to wonder if I could make a simple 'economy' bevel by simply overlaying a piece of ebony veneer on top of a carved bevel without any binding. It looks like that would work pretty well, especially if the guitar was bound in ebony:

Repeat with a layer of maple or whatever your binding wood is, and you could have faux binding with very little effort: