I 'eyeball' the arch/carve shape, but you can always draw out a contour on some card and cut it out for reference if you like. Like Brock says, there's a basic map in the MIM library.

I always route a flat around the perimeter, but not the inside of the horn/horns, sometimes drill holes to indicate the right depth (mapped out, Benedetto style), and have at it with an angle grinder and a 60 grit disk. And a GOOD dust mask. And do it outside. And some padded gloves against the vibration. Then spend about 20 minutes or so carving, and with a bit of practice you can get very, very, very close indeed. I finish up with an orbitoal sander, finger planes and scrapers for various details (recurve, tighter curves, refining the shape, etc.)

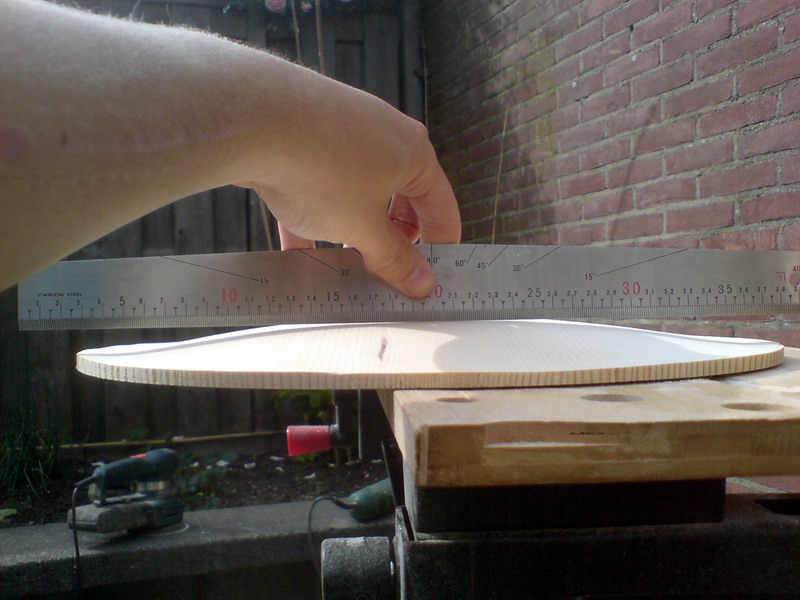

Last carve I did was in spruce, for an 'electric archtop', inside and out, with a shot of the flap disc used for most of the grunt work. Those pesky pitch lines were hidden in the original blank: