Tail block may have a curve,

But you wouln't cut that curve on a saw

Head block may have a curve, if there's a cutaway may be curved as well

Same again, you wouldn't cut that curve on a saw

Fretboard is curved

One more time, that curve isn't cut on any saw

Bridge usually has some curve on the top

The top side of the bridge, if curved, isn't cut on a saw

Sides of course are curved

Ah ha! We have one. But this one's easily cut with a $10 jig saw and fine blade. Or with a template and Zip cutter in a router jig.

The back side of the neck is curved as well as the transition from the heel to the neck shaft

We don't carve a neck with a saw; the heel transition does use a saw if we have one handy.

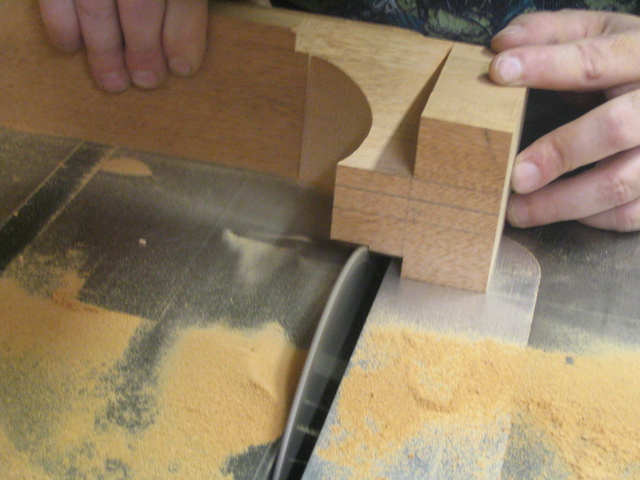

See my point? While there are a few places where the band saw is very handy, they are actually very rare. The table saw cuts straighter, cleaner, truer than a band saw. and with a few home made jigs, it can do so much more, and yes, even cut curves and the radius of neck and end blocks. And a good carbide table saw blade can cost under $20, lasts for years, and takes one minute to change.

I'm glad I have both, but if I only had to have one...... In fact, I have 2 table saws....

.

|