This is the first time that I have used West Systems epoxy to glue a fret board to a neck and I wanted to share my impressions with my OLF pals.

The move to epoxy from Titebond was to avoid the slight amount of warping that I seem to always get when using Titebond. Although this warping was very slight it would require me to spend extra time leveling the fret board.

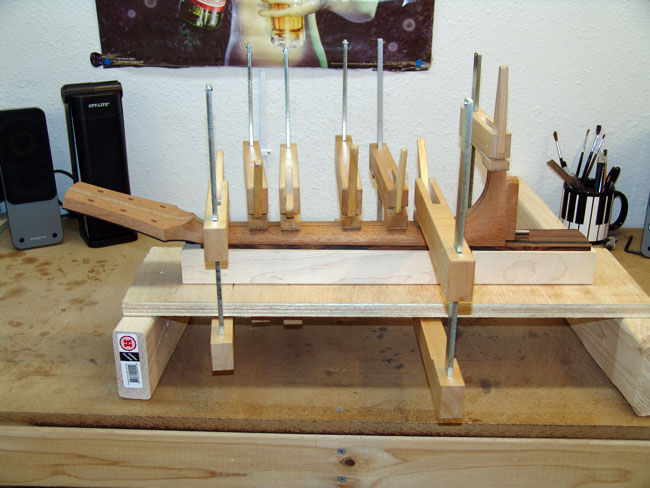

In addition, this was my first time using a product that John Watkins sells - a radiused, hard maple fret board caul.

West Systems epoxy is a real pleasure to use and I bought the stuff pre-packaged in single use packs. It mixes very easily and completely and paints on thin enough that it tends to self level itself. once clamped there was squeeze out all around but the squeeze out was not runny and very easy to clean up some what before it cured.

To my surprise, since I have sanded epoxy before in a prior life, this stuff sands like a dream and did not clog the paper at all. I am very impressed with West Systems and will be using it again where ever it makes sense to do so.

John's fret board caul was also a pleasure to use. Prior to applying the epoxy I did a dry run with my clamps and checked for gaps and there were none. The caul also has dimples in if for registration pins and the area over the truss rod is routed out so as to not apply pressure there.

It all went very well, very fast, and I am very pleased with the results. The fret board when checked with a straight edge is perfectly level which is better then any other time I have glued one on in the past with Titebond.

Here are some pics.