Oh and the Grizzly sander posted above is probably what you were looking for, right?

Most of my previous post was for the shaft.

Most of my previous post was for the shaft.

| Official Luthiers Forum! http://w-ww.luthiersforum.com/forum/ |

|

| Shaping Necks http://w-ww.luthiersforum.com/forum/viewtopic.php?f=10102&t=15199 |

Page 1 of 3 |

| Author: | mgcain [ Tue Jan 01, 2008 2:42 am ] |

| Post subject: | |

I have the EXCELLENTJohn Mayes DVD's on building that I've been studying all through the holidays here. John uses his stationary Belt Sander to shape the neck and the heel. Seems pretty efficient, but I don't have one. So how do you all do it? I could carve and shape it with a spokeshave, but I was looking for a more efficient method... Pics please if you have them! Mitch |

|

| Author: | Dave Anderson [ Tue Jan 01, 2008 2:52 am ] |

| Post subject: | |

I like this sander a lot for shaping my necks Mitch. Grizz |

|

| Author: | David Collins [ Tue Jan 01, 2008 2:54 am ] |

| Post subject: | |

I've never personally found any big draw toward using a spoke shave. Course rasp and scraper have pretty much always been my tools. I do use a band saw for removing a lot of the bulk before I start hand shaping. |

|

| Author: | Terry Stowell [ Tue Jan 01, 2008 3:24 am ] |

| Post subject: | |

Spoke shave or draw knife DOES have some merit...It produces shavings and almost no sawdust. BUT, it will leave facets that will need to be leveled out (sandpaper). The big caution with a drawknife, is that it will tear out a rogue grain (african mahogany) and it doesn't care if it's the last stroke on a neck, and leave a huge gaping wound. There are MANY ways to do this carve a neck. I'd recommend you get a couple rasps, a straight edge, some hard and soft sanding blocks, 3 grits of sandpaper, and got to town! Many more will input, and some might have pix |

|

| Author: | Terry Stowell [ Tue Jan 01, 2008 3:28 am ] |

| Post subject: | |

Oh and the Grizzly sander posted above is probably what you were looking for, right?  Most of my previous post was for the shaft. Most of my previous post was for the shaft.

|

|

| Author: | Hesh [ Tue Jan 01, 2008 3:33 am ] |

| Post subject: | |

To shape my necks I use a cell phone - and call John Watkins......  Hey - it's a new year and some of us never learn anything........   |

|

| Author: | DannyV [ Tue Jan 01, 2008 3:52 am ] |

| Post subject: | |

Having only done one so far, but made a fair sized mountain of power tool sawdust and chips over the years, there is a lot to be said for making long, curly mahogany shavings with a nice, sharp spoke shave. Pretty therapeutic for me. Don't know about the rest of you but I need that some days.

I guess it comes down to how fast a production you want. There's always CNC. Happy New Year, Danny |

|

| Author: | Terry Stowell [ Tue Jan 01, 2008 3:54 am ] |

| Post subject: | |

That's funny Hesh. I did use one of his premade necks successfully, in a hurry. Saved some time. Of course, I still had to shape that rectangular paddle into a curvy headstock though... It's a great option. Back to our original question.... Anyone post some pix for mitch? |

|

| Author: | joelThompson [ Tue Jan 01, 2008 4:35 am ] |

| Post subject: | |

Band saw to remove the bulk then rasp and chisle. I also like to use a violin makers knife to carve the heal becouse it avoides chipout if you have any laminates in your neck. apart from that my favourate tools are a medium hand cut cabenit rasp (herdim) for rough shaping. then a micro plane rasp along with a fine hand cut rasp for final shaping. Then i use a good sandpaper such as lubrasil to finish. Allthough i do use a number of other tools including a spokeshave. Its just a matter of finding the tool that feels right for you. You will know when you find it. This a job a love doing and i dont think i will ever tire of doing it. Please bear in mind that i allways use use hand tools where possable so i cant comment on the belt sander method allthough it looks like you can very good results very quickly using it. Have fun, Joel. |

|

| Author: | Terence Kennedy [ Tue Jan 01, 2008 4:42 am ] |

| Post subject: | |

Happy New Year! I use the inflatable Grizzly drum sanders on a hand drill to shape the heel. Then rasps, and scrapers and sandpaper to fine tune. I use a trick Charles Fox taught us for the shaft. Shape the exact profile at the 1st and 10th frets (for a 14 fret) using, rasps, sandpaper sticks etc. until your templates fit perfectly. Hog off most of the excess wood in between with whatever you like. (I'm using 40G on an air sander right now.) Then get a flat piece of 3/4" particle board cut to the same length as the distance between the 1st and 10th frets with the edges rounded a little. Cover it with 80G self adhesive paper and put a 1" strip of the brown StewMac binding tape on each end so it rides on the profiled areas. Sand horizontally with this and it will blend the shaft with the previously profiled areas and come out really flat. You can then finish the transition from the heel to the 10th fret with the drum sanders on a drill and the usual array of tools to get the final product. I'm sure the more experienced guys just whip the whole thing out freehand on a belt sander in 15" but this is pretty foolproof for beginners like me. I do have a little template for the heel profile that works great with a RoboSander. This should get you there I hope. http://kennedyguitars.com/Kennedy%20Guitars/Heel%20Profile.h tml Terry |

|

| Author: | Terence Kennedy [ Tue Jan 01, 2008 4:46 am ] |

| Post subject: | |

Take out the extra space in html (the h tml) before you paste. I can't seem to get the hyperlink feature to work with FireFox on my Mac. Sorry TJK |

|

| Author: | Arnt Rian [ Tue Jan 01, 2008 4:53 am ] |

| Post subject: | |

I use the band saw to cut away as much as possible, then move on to statinary belt sanders, drum sander and drill press sanding drums to quikcly shape the headstock and the rough out the heel. Draw knifes and spoke shaves work OK for the neck shaft with unfigured, plain woods, but that is the easy part anyways. Chisel and rasps form the heel / headstock transition, and for woods like curly maple only rasps and abrasives for all final shaping. |

|

| Author: | grumpy [ Tue Jan 01, 2008 5:23 am ] |

| Post subject: | |

Lancelot, rasps, files, big sanding block and 80 grit, scrapers, 280 grit sandpaper. in that order. |

|

| Author: | James Orr [ Tue Jan 01, 2008 5:31 am ] |

| Post subject: | |

Great thread. After the thread two weeks ago about being able to carve a neck, I'll feel like a poser until I can, and I'm looking forward to trying. |

|

| Author: | davidmor [ Tue Jan 01, 2008 5:47 am ] |

| Post subject: | |

I use a sanding drum in my drill press, microplane rasps, scrapers, sanding blocks, and sandpaper in my hand. The bulk of the wood and shaping is done with the sanding drum and drill press though. |

|

| Author: | Wes McMillian [ Tue Jan 01, 2008 7:13 am ] |

| Post subject: | |

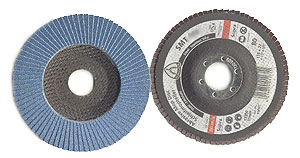

Or, if you have access to a 4" grinder but the Lancelot is too intimidating, these things do a killer job at stock removal and can leave a pretty slick finish. It does still require a light touch. You will be surprised at how quick you can remove stock with a 36 grit disc! Pop it off and put on a higher grit and they can slick off pretty well, too. Other than that, I have two 4" belt sanders - one with 40 grit and one with 80. I hog off the majority of the stock around the heel with one then swap right over to the other without missing a beat.

|

|

| Author: | Wes McMillian [ Tue Jan 01, 2008 7:14 am ] |

| Post subject: | |

And, of course, I still finish up with the typical hand tools and sandpaper. |

|

| Author: | letseatpaste [ Tue Jan 01, 2008 7:24 am ] |

| Post subject: | |

I've only done one neck so far, but I used a chisel and rasp at the heel, and a spindle sander to start forming the transitions at the heel and at the headstock. I used a little Ibex finger plane for shaping the shaft and that worked out really well, easy to control but it works quickly. I used a flat sanding block after the Ibex to smooth things out and make sure the shaft was straight. |

|

| Author: | Rod True [ Tue Jan 01, 2008 8:00 am ] |

| Post subject: | |

Sharks with frickin' laser beams strapped to their heads.

OK, seriously. I get the thickness with my router (tutorial to come sometime in the near future) cut taper on the bandsaw, glue one the fretboard, trim the neck to match the taper of the fretboard on the router table (watch out for the nut end of the fretboard), than it's rasps, files and sandpaper. |

|

| Author: | Steve Saville [ Tue Jan 01, 2008 8:09 am ] |

| Post subject: | |

I bought John Mayes video on neck carving. He did almost the whole thing on a bench top belt sander. It was amazing. I do most of it on the bench top belt sander following up with 5" RO sander and then finish with hand sanding. |

|

| Author: | LuthierSupplier [ Tue Jan 01, 2008 8:36 am ] |

| Post subject: | |

I've got some videos on my website from Edward Dick's CO School of Lutherie that shows his method of carving a neck. You can see the videos HERE I've John's neck carving video too, and it is very nice. You just need to find the method that works for you after some trial and error. There is no greater satisfaction than carving your own neck! Good luck! Tracy |

|

| Author: | Dominic [ Tue Jan 01, 2008 8:37 am ] |

| Post subject: | |

Best tools I bought for this were the Stew Mac Dragon files. Best rasps I have ever used. With mahogany I can't see any reason to use anything else apart from a spoke shave to remove the bulk. With maple I use the band saw to get the bulk off. Then rasp to clean up marks and do the heal and finally a piece of stiff sanding belt (stiff so it does not conform to the rough neck shape) and sand it like a shoe shiner. I've had heaps off experience shaping things in a previous life as a surfboard shaper so I find this task quite easy and satisfying. Only takes about 20mins to finish a neck. Happy New Year BTW Dom |

|

| Author: | DP LaPlante [ Tue Jan 01, 2008 9:57 am ] |

| Post subject: | |

Drawknife then spokeshave for the shaft, laminated swedish steel knife (from woodcraft) for the heel, Nicholson four in one rasp/file overall then 80 grit on up. |

|

| Author: | FishtownMike [ Tue Jan 01, 2008 11:13 am ] |

| Post subject: | |

[QUOTE=DaveAndy] I like this sander a lot for shaping my necks Mitch. Grizz[/QUOTE] Dave I was looking at this before. It attaches to a hand drill and looks like it might be awkward to use with a drill. My two cordless are heavy and I think it would be and issue. And is the drills speed sufficient enough? |

|

| Author: | James W B [ Tue Jan 01, 2008 11:59 am ] |

| Post subject: | |

I`m thinking you wanted some pics of some necks.  Okay just kidding. Here`s what I like.Not what you can get from a bought pre carved,but it appeals to me. Okay just kidding. Here`s what I like.Not what you can get from a bought pre carved,but it appeals to me.

This is one of the most rewarding parts of building a guitar for me.Check out Robbie O`Briens video available from LMI,It really explains neck carving in a way that is easy to understand.I use a spokeshave and a # 49 Nicholson Rasp, and then sand as in Robbie`s video.Hope this helps. James W B

|

|

| Page 1 of 3 | All times are UTC - 5 hours |

| Powered by phpBB® Forum Software © phpBB Group http://www.phpbb.com/ |

|