A while ago I made the mistake and watched the Taylor Guitars Factory Friday video on the side bending. If you have not seen this then you must check it out! I was amazed by the way Taylor was able to bend sides and reduce the number of variables to just one. They only vary the bending speed (slow and fast) and everything else is the same for all woods! Of course I am sure that the Taylors benders cost big $$$ so at first it didn't seem possible building a bender similar to theirs.

After some thought I did figure out how I could use many of the concepts Taylor used without fully automating the process like they do.

So here is my side bending process that uses many of the same principles as Taylor. Please note that this project was lots of work and by no means is a quick fix to making a better bender. My goal was the design a better process. If your goal is to build guitars then just build a Fox or Doolin and get to work. If you enjoy designing and building a better process than you may find this interesting.

Before I start here are a couple facts that I picked up in my research on bending wood that I think are worth noting:

1) Heating or steaming wood radically changes its compression properties but has no effect on its tensile properties. What I gained from this is that if heat is applied to the inside of a bend it will be most effective..this also ties into what Taylor does.

2) Heating dry wood will create moisture but since the wood will dry out quickly using this approach it is important to only apply heat to the areas that are being bent and not the entire piece of wood.

3) Using stainless steel slats under tension helps keep the wood from breaking at the outside of the bend... the point where the wood is highly stressed (tensile) from the bending process.

I will walk though the steps and hopefully you will get the idea.

Sample Walnut, .102 thick

Wrap in kraft paper

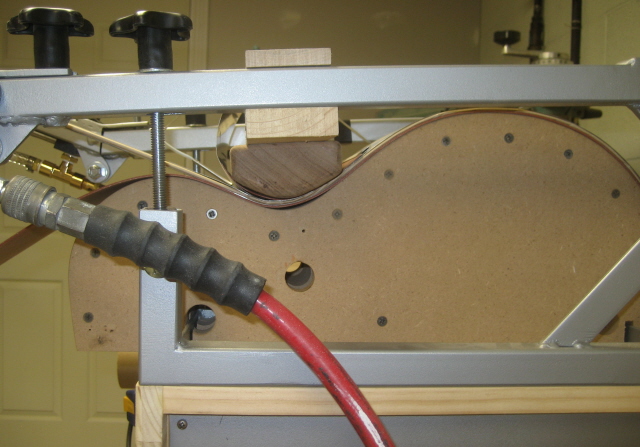

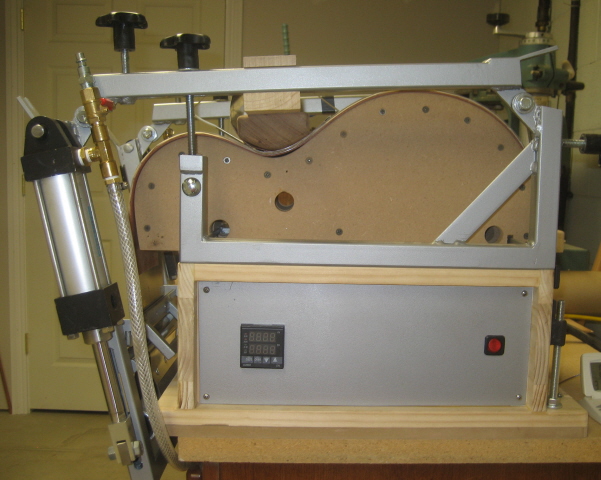

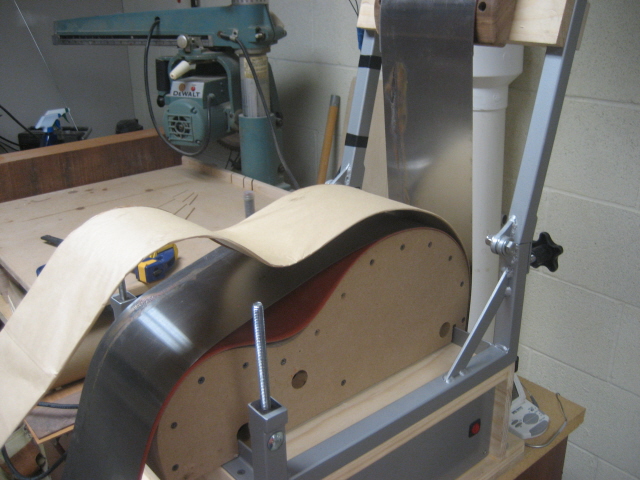

Bender is heated to 280-300 degress AND then the wood is loaded into the bender. I only want to heat the wood when I am bending to not dry it out.

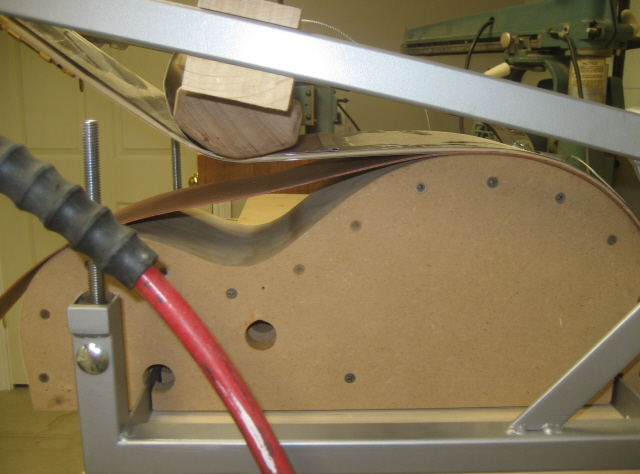

At this point I support the upper arm of the bender, hook the lower slat with the upper slat and apply 40 psi to the air cylinders to pull the slats in tension.

I bend the upper arm back which creates about 75% of the waist bend.

Keep in mind that I have a 5 x 6 heating blanket at the waist caul to just heat the waist.

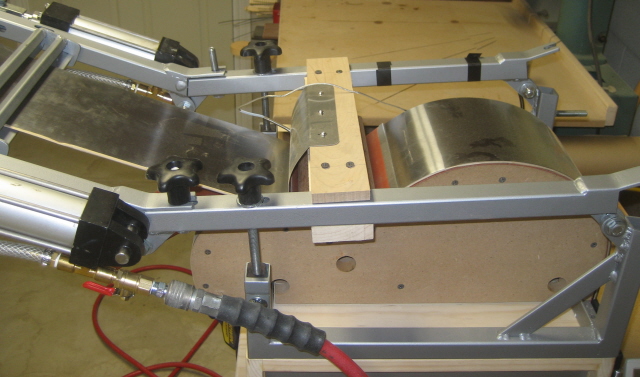

Bending the lower bout.

I now tighten two clamp knobs that brings the waist in tight with the form.

Bird's eye view. Ready to bend the upper bout.

Bend the upper bout.

Let the wood cook for a few minutes (still working on how long)

I release the pressure on the air cylinders and un-hook the lower slat from the the upper slat.

I return the bender arms to the original upright position. This leaves the bent wood on the mold which can easily be removed and the process started over for the next side.

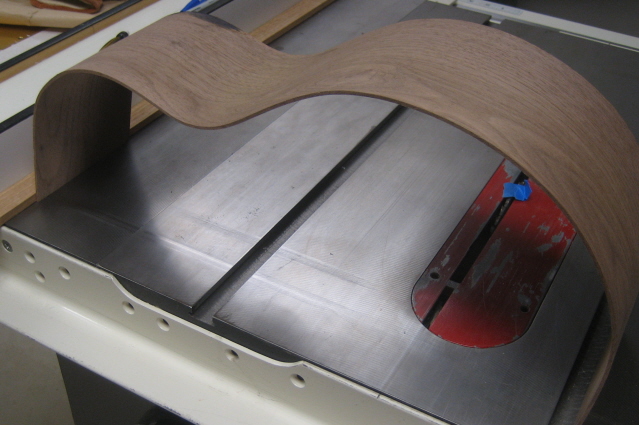

Ahhh....a newly bend side. (I have the side clamped between my table saw fence so it looks like there is no spring back but there is some)

Since the sides are bent dry they don't cup, distort, or discolor.

I am still working out the details but so far I have bent about 10 sides for testing and the results are very good. I even bent a curly maple side at about .120 thick just to push it and it had two small cracks in the waist.

Maybe this will inspire a few new thoughts on side bending.

And no...I don't plan to make these for resale.