1. Wear a nitrile glove when sanding. That way you sand the glove rather than your finger tips.

2. Or, get a disk sander for your drill press. I highly recommend this. It's just a hunk of aluminum disk or other metal that you chuck into your drill press. Use PSA sandpaper. I use it for many things.

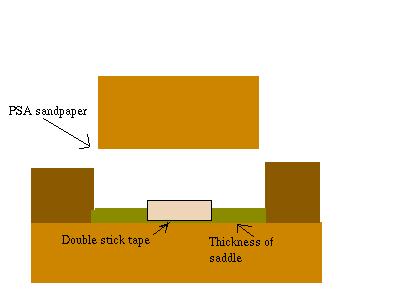

Thickness saddles and nuts. I make a holder for the saddle/nut by taking a piece of flat wood, and then glue on two little pieces of thinnish veneer onto it with superglue in a "L" shape. This will hold the nut or saddle while sanding it. Using superglue, you can have your holder ready to go in 5 minutes. If you don't have 1mm thick veneer, just make it with the sanding disk! Or glue thick wood on, and thin it down afterwards!

Adjust height of saddle. I put it in a adjustable angle vise, and sand it down to the proper height. I do the same thing to adjust the height of my nut, and to put in the angle to the top.

I also use this disk set up to flatten out the scarf joint of my necks after glue up, to thickness headstock veneer, to make veneers for rosettes, tail inlays, etc.

I actually have two, one with 120 grit, and the other with 320 grit.

I bought mine from Greg Matonis of Gilbert Tuners, though I think there are other sources out there. http://www.gilberttuners.com/

|

Does anybody have any secrets they'd like to share for thinning saddles to the proper thickness, with out letting your finger tips ride the edges and rub the sandpaper! I'm not whining! Really I'm not! But shish!

Does anybody have any secrets they'd like to share for thinning saddles to the proper thickness, with out letting your finger tips ride the edges and rub the sandpaper! I'm not whining! Really I'm not! But shish!