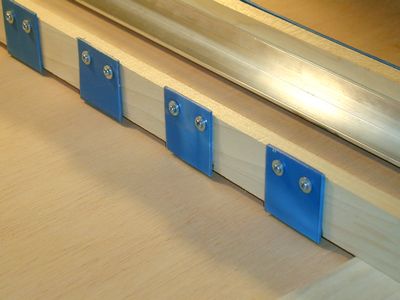

Router/Planer in Use

In this case some case-hardened cocobolo slices. After sawing these last year they cupped badly on the outer slices of the 1" boards. Inner cuts weren't bad at all. You really don't want kiln-dried planks for luthierie, air-dried is preferable to eliminate or minimize case-hardening.

So, I've learned to relieve this case-hardening by attacking the outer part of those planks. Another thing is to add moisture to the inner side, allowing it to swell these pieces toward flat. Yes, wet only the concave portion, leave the other side dry.

Enter the Router/Planer, it is relieving this case hardened wood off the opposite side of the bookmatch. Keep the bookmatch at all costs, plane the opposite side only. Well, it's work, what can I say. But this beautiful and, otherwise, worthless to the luthier wood, can be reclaimed.

That said, suppliers of quality flat tonewoods are to be applauded, especially in the more dense and resinous hardwoods similar to Cocobolo or really oily Indian Rosewoods. Could you do this with one of those really small planers, of course. I'm just not sure of how thin it could go.

I took this stuff down to .150 / .170 and then headed to the drum sander. You guessed it, it crapped up the belts and ruined them. But I used to crap up way more than one set. I'm happy with my little Router Planer. And I would like to add one more thing, "Beat Ya, John K." I took about .050 to .070" off in a pass.