Not to my way of thinking...

The barrel bolts sit in the very very back of the tenon so there's lots of wood holding them there, John Mayes uses the inserts but I'm not convinced about them

-paul-

| Official Luthiers Forum! http://w-ww.luthiersforum.com/forum/ |

|

| Making JIgs, Some Technical Questions http://w-ww.luthiersforum.com/forum/viewtopic.php?f=10102&t=2996 |

Page 1 of 2 |

| Author: | Sprockett [ Fri Aug 26, 2005 9:46 am ] |

| Post subject: | |

Hey All... I'm in the process of re-working the shop and making some jigs to make my life a little easier and remove me from some operations. The main jig I'm doing will be one to do all the operations for the mortise and tenon I've been using, I want to make them %100 uniform and make the process simpler, so here's my random thought process on this.... 1. My neck blanks are always 3" wide so I will build the jigs to fit for this. 2. I'll make a routing jig for the truss rod slot and the two CF slots. 2. I want to be able to clamp the blank in and do the following operations before I remove it: a. Drill the bolt holes from the side that go into the tenon. b. Drill the bolt hols in the end of the tenon. c. Using a router, cut the tenon with a small amount of set to the cut so the neck is set correctly once it comes out of the jig. Then I'll build a second jig that will allow me to route the mortise in the heel block and drill the bolt holes. So a couple of questions... 1. Does anyone have pictures or a drawing of ones that they use or have seen, I don't want to re-invent the wheel, but I would like to avoid others mistakes. 2. On the router should I use a flush cutting bit or should I use a collar and a sized bit?? A collar means you have to put an offset into your pattern. Any comments or ideas would be greatly appreciated, I've decided to take this down time and put some of these operations into the automated bin. I've been doing them by hand so far, it's a good skill builder but it takes time, having something that I whip out consistently in a short amount of time would be a godsend in the shop... Thanks -Paul- |

|

| Author: | LanceK [ Fri Aug 26, 2005 11:50 am ] |

| Post subject: | |

Paul, have you seen the cool jig Paul Woolson made for getting the correct back set angle on the tennon end of the neck? Ill browse the archives, I know its there some where. |

|

| Author: | Sprockett [ Fri Aug 26, 2005 12:01 pm ] |

| Post subject: | |

Cool... Seems I need to hook up with Mr Woolson to get some stuff from him :) Thanks -Paul- |

|

| Author: | Don Williams [ Fri Aug 26, 2005 12:36 pm ] |

| Post subject: | |

Ive been looking for that too....where is it, and why isn't it posted on the Jigs & Fixtures page????? |

|

| Author: | Keith M [ Fri Aug 26, 2005 1:52 pm ] |

| Post subject: | |

Try this link. http://luthiersforum.3element.com/forum/forum_posts.asp?TID= 1593&PN=22#17301 |

|

| Author: | Sprockett [ Fri Aug 26, 2005 2:42 pm ] |

| Post subject: | |

Yep that's what I was heading for.... I like his depth idea for setting the angle... good stuff.. Isn't NPalen using one made for the table saw?? I'll have to check that one too... One advantage that the table saw has is that it cuts cleaner and you can put an angle in using that as well... Thanks All.. -Paul- |

|

| Author: | Shane Neifer [ Fri Aug 26, 2005 3:49 pm ] |

| Post subject: | |

Just a question from a totally inexperienced builder but wouldn't inserts in the tenon end offer less chance for future failure than barrel bolts? I know that Cumpiano used/s them but he also used to use drawbore dowels. Inserts are newer technology and can be used without removing as much wood from the tenon. Also, they would result in one less step as then you only have to drill into the end grain. Although probably unnecessary I think I would still epoxy the inserts in just to lock them. I still have this feeling that metal into wood is not as good as wood in wood. There are a lot of VERY OLD timberframe buildings with wood connections but most metal connections on old buildings see wood moving away from the metal fasteners. Anyway Paul, if you are setting up a new shop and better processes this is just another thing to consider. Shane |

|

| Author: | Sprockett [ Fri Aug 26, 2005 4:06 pm ] |

| Post subject: | |

Not to my way of thinking... The barrel bolts sit in the very very back of the tenon so there's lots of wood holding them there, John Mayes uses the inserts but I'm not convinced about them

-paul- |

|

| Author: | Shane Neifer [ Fri Aug 26, 2005 4:29 pm ] |

| Post subject: | |

You are right, there is a lot of wood in front of the bolt, in timberframing we call that 'relish'. But I do note the location that the neck on Paul Woolson's guitar broke looks like right at barrel bolt (In his sickening sad "I sold a guitar at HB afterall" post). I understand that Taylor just uses the inserts without a tenon at all, just a butt joint. I bought some inserts and bolts from Lee Valley as I was planning on using a tenon and then putting in inserts and bolting through the neck block but have decided to just use the traditional dovetail, if I'm making a jig anyway I thought I may as well stay with wood to wood. Anyway, just thought I would throw out another option that could save you a step, decrease the room for error and probably offer you the same level of strength and in my most humble opinion give you more strength! If you want I can take a picture of the inserts and bolts for you and post it, but if you are OK with what you got, I won't. Cheers Shane |

|

| Author: | Sprockett [ Fri Aug 26, 2005 4:44 pm ] |

| Post subject: | |

Well you can never know enough so go ahead and post it and maybe I'll give it a try on the prototype one I'm doing... -Paul- |

|

| Author: | Colin S [ Fri Aug 26, 2005 7:49 pm ] |

| Post subject: | |

I always put a hard wood dowel (ash) vertically in my tenons so that the barrel bolts/cross dowels pull against vertical grain. I believe Kathy Matsushita uses one as well with the butt jointed inserts as well. The dowel stops the pull being against end grain. Colin |

|

| Author: | Mattia Valente [ Fri Aug 26, 2005 11:54 pm ] |

| Post subject: | |

I've used inserts so far, but I'm going to give barrel bolts a shot on the next one. I will have a laminated tenon/neck blank, though, so that should further increase stiffness. Since I'm going to be test driving an adjustable neck joint, inserts are kind of out of the question. I used cross-grain bits in the heels with the inserts as well, and I feel both systems are more than up to the task. I don't think either would've prevented the damage Paul W's guitar sustained to the neck, personally. Paul: personally I'd use a pattern/template bit over a collar any day. You can never guarantee the collar will be perfectly centred on your router's spindle/collet, while ball bearing bits are by definition self-centred. |

|

| Author: | Dave-SKG [ Sat Aug 27, 2005 12:29 am ] |

| Post subject: | |

I don't use Barrel bolts I use inserts. But I always re-inforce that part of the neck with a dowel. no tenon, just butted neck to body. I have never had any problems. |

|

| Author: | Brock Poling [ Sat Aug 27, 2005 3:22 am ] |

| Post subject: | |

Yeah I do that. I don't know if it ** really ** helps or not, but I "think" it does. |

|

| Author: | Dave Rector [ Sat Aug 27, 2005 3:31 am ] |

| Post subject: | |

I do that as well. Not sure if it helps or not, but it makes me feel all warm and fuzzy. |

|

| Author: | Sprockett [ Sat Aug 27, 2005 3:52 am ] |

| Post subject: | |

OK gang.... Now that I have some coffee I'll give you my thoughts on this... There is about 180lbs of pressure pulling on the neck from the tension of the strings (this is a big grain of salt average so bear with me), sounds like alot and in some respects it is. However if you consider that most necks are only set to about a 1 to 2 deg angle most of that pressure is pulling the neck back into the guitar and not pulling the neck with much upward force (if it was then you would have a neck in very bad need of a reset). Keeping that in mind inserts are more than strong enough to hold the neck in position, they simply don't have to carry much force to hold the neck in position. Now as to dowels.... I have a couple issues with dowels: 1. For tenon bolts like I do, you would have to drill through any dowel to get into the barrel bolt (the dowel would be in front of the barrel bolts), essentially if your going to do that then you've negated the whole point of putting the dowel in. 2. If you use inserts and a dowel the same holds true, you will have to drill through the dowel to have any effect and that will kill the reason you put it in there in the first place. You could put the dowel behind inserts and that would help some, but with enough force you would simply split out the end. In some respects I think we are over engineering this area, Woolsons guitar broke at the point of the insert because when it hit the ground (remember it's not the fall that kills you but the sudden stop at the end) it had to give somewhere. The insert being the logical place because the wood was thinner there, but if you think about the amount of force it doesn't really matter what he used, the heel was going to give at some point. A dowel might have helped but I am sure it would still be broken. So I think for my new design I'm going to switch to a little thicker and shorter tenon and use inserts, however instead of CA I'll use epoxy on the threads because it has better bonding properties with metal and will not wick into the wood like CA does (which is very useful for other things). When you glue metal and wood nothing beats epoxy, CA is really good for lot's of things but does not do very well on metal. I'm going after light so I'm working on a modification of the 3 piece mortise block that CFox is using.... Cheers -Paul- |

|

| Author: | Dale M [ Sat Aug 27, 2005 3:53 am ] |

| Post subject: | |

I cut my M&T on my table saw. I mortise the neck block before assembly. Simple, straight forward operation. I glue a small filler block in the botton of the mortise to limit the neck travel downward. Then after the body is out of the mold I establish the precise neck angle with a try square. I cut that angle on the end of the square blank and saw the tennon using my miter gage and rip fence. I get air tight joints that require a little gentle persuasion to assemble. I cut the tennon at a 2deg angle so that the first contact between neck and body is the outside edge . Usually no fitting is required after pulling up with the bolts but sometime I pull a piece of sandpaper between neck and body to tighten a joint. Simple , quick and I don`t have to listen to that $@#%^$ router run! This method can be used to cut a straight dovetail joint. I`ve already made a test cut and plan to use it on the archtop I`m starting. As much as possible I use the KISS method in everything I do! Try it, you`ll like it! |

|

| Author: | Dave Rector [ Sat Aug 27, 2005 6:07 am ] |

| Post subject: | |

[QUOTE=Sprockett] however instead of CA I'll use epoxy on the threads because it has better bonding properties with metal and will not wick into the wood like CA does (which is very useful for other things). [/QUOTE] Paul, I just wanted to clarify one thing. I am not counting on a bond between metal and wood when using the CA. I only use it because I think it will make the threads in the wood a little harder/stronger and help keep the insert from pulling out. The wicking factor of CA seems to soak right into the grain. |

|

| Author: | Sprockett [ Sat Aug 27, 2005 6:10 am ] |

| Post subject: | |

That it will Dave, but just keep this in mind... When you make a jig and have a bolt or metal and wood together epxoy is the thing to use because it creates a strong bond between the two. Once I put an insert in I don't want to take it out again so I'll epoxy it and never have to worry about it again... Cheers -Paul- |

|

| Author: | Shane Neifer [ Sat Aug 27, 2005 1:34 pm ] |

| Post subject: | |

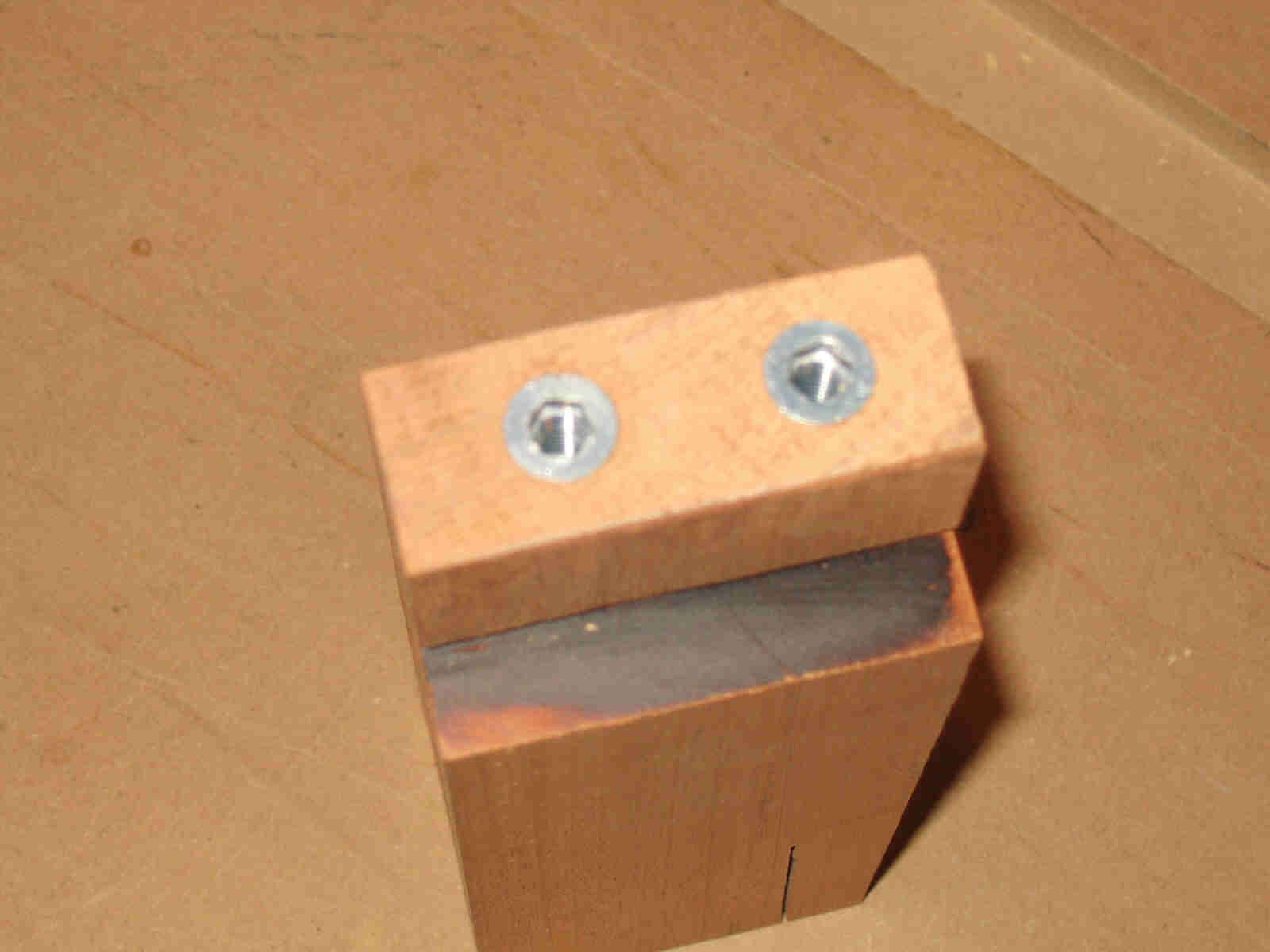

OK Paul, as promised! Sorry for the delay but I spent the day in the shop cutting up some awesome cedar tops! So the first picture shows the amount of gear needed. In this case I used my drill press but I think I would make a jig by drilling holes through a block of wood for the 1/4 inch bolts but I would find some brass or bronze tube that had a 1/4 inch ID and I would drill for the OD and glue it into the wooden block and I would use that as my drill guide. I hope you understand what I mean. I can't fit the end of a neck under my drill press unless I do some fiddlin'. So I use a 1/4 inch brad point to drill through the neck block and into the tenon at the same time. They will always be lined up then. Then I use a 5/16 normal bit to enlarge the holes in the tenon to accept the inserts. The rest is pretty straight forward and I think the pictures should show it all. Hope this useful.

The picture below shows the inserts installed.

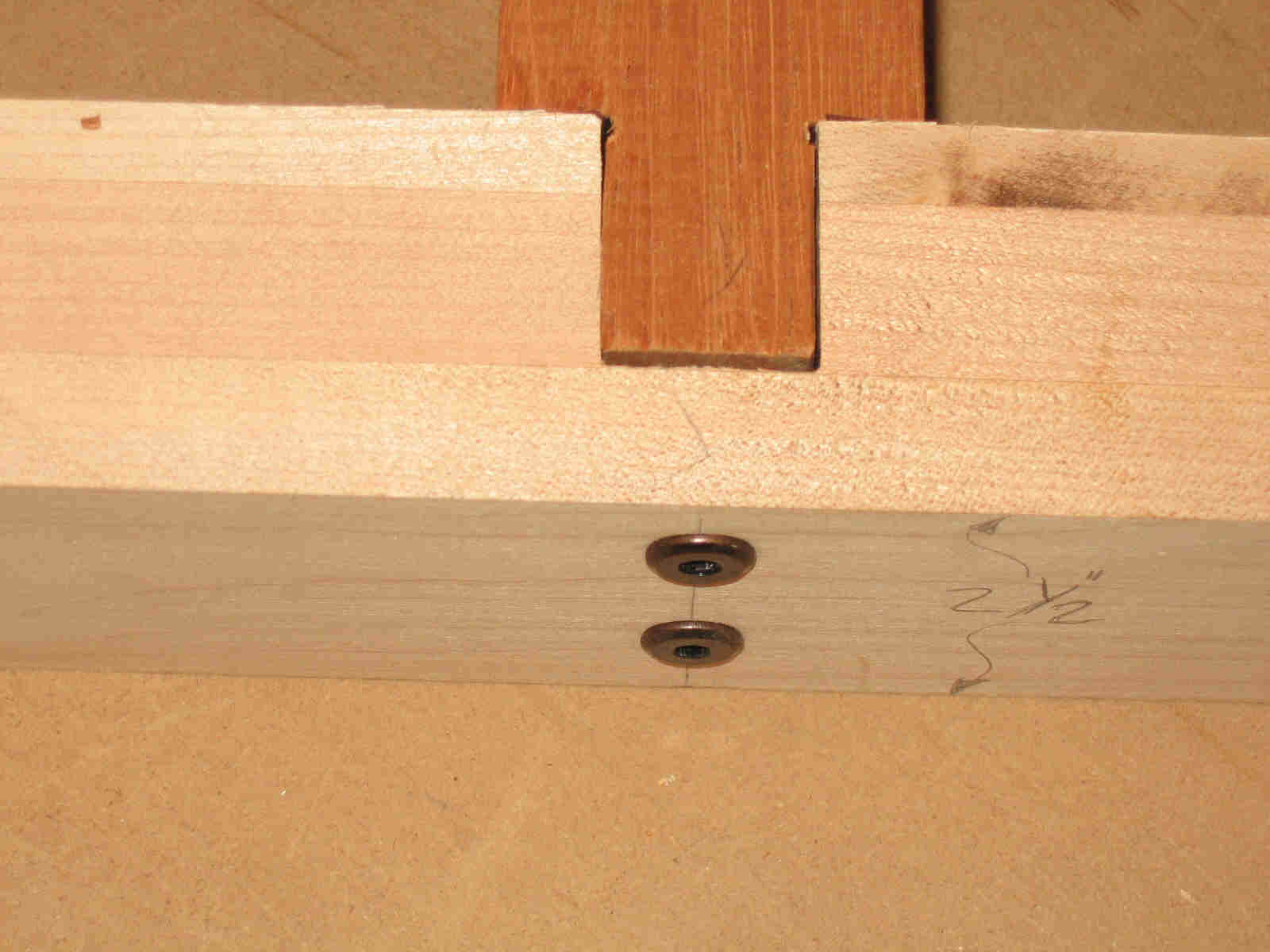

This picture shows the neck and block joined together

And a top view. This was a pretty a crude tenon and of course much better care (a sharper blade, this was done at a friends and not on my uni-saw)would be taken for a guitar neck tenon.

I got to tell you it was very quick and very accurate, even with almost no care in the set up. It might get me rethinking this option over dovetails! Shane |

|

| Author: | Dave Rector [ Sat Aug 27, 2005 11:25 pm ] |

| Post subject: | |

Shane, where do you get the inserts with a hex drive in them? I have looked for something similar but am unable to find anything locally. |

|

| Author: | John Mayes [ Sun Aug 28, 2005 12:30 am ] |

| Post subject: | |

that is the exact same hardware I use. And dave you can find the inserts like that that are hex drive at ace hardware. I'm totally confident in the stability of the inserts. Dana has used them for thousands of guitars and I've never heard of a insert failing. |

|

| Author: | Dave Rector [ Sun Aug 28, 2005 3:05 am ] |

| Post subject: | |

Hmmm, guess I need to check out a different Ace store. I just looked for some of those last week or so and my local Ace didn't have them. There are about 10 more of them within a 5 mile radius around here, I'll just try a different store. |

|

| Page 1 of 2 | All times are UTC - 5 hours |

| Powered by phpBB® Forum Software © phpBB Group http://www.phpbb.com/ |

|