Shane is that steal or steel?

Doug, I use to work at the same steel fab shop that my friend does, (his dad is the owner). I worked as a mechanical engineer tech, (machanical draftsman) I use to help design machinery and other mechanical stuff.

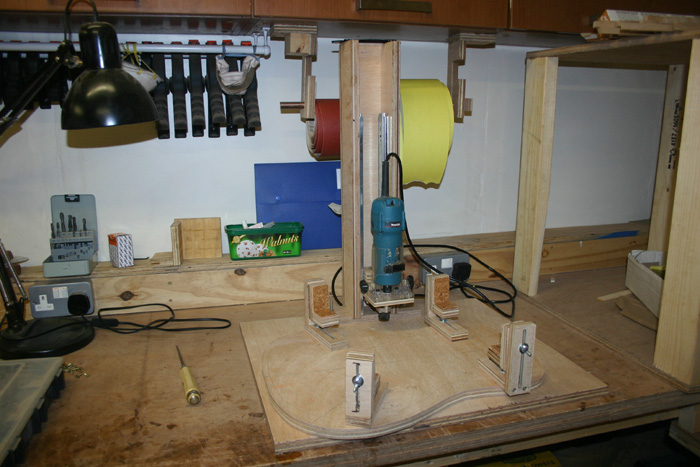

So I had the guys in the shop make the drum for me, I use to draw this kind of stuff up all the time. It's amazing how much work your shop buddies will do for you for a case of beer. That drum took them 12hrs to make, it has a T.I.R of 0.002-0.004" better than I could ever do with MDF and a "flat" sanding board. To align it to the deck I used two milled pcs of steel and adjusted the bearings with a take-up screw I built into the machine.

There are lots of good information out there regarding making a thickness sander and I bet someone here has some plans readily available. I don't have the software that I used to make it anymore otherwise I would just give them to you.

The onlything I need now is an autofeeder for it. Just havn't bothered getting to it yet, but one day soon.

The other thing with the sander is making sure you have it turning at the correct speed. for the first 3 years, I had it turning at 600 rpm, way to slow, now its at full speed and is much smoother and cuts way better.

|