You mean this?

| Official Luthiers Forum! http://w-ww.luthiersforum.com/forum/ |

|

| Plate joining http://w-ww.luthiersforum.com/forum/viewtopic.php?f=10102&t=3743 |

Page 1 of 2 |

| Author: | John How [ Mon Nov 07, 2005 3:08 am ] |

| Post subject: | |

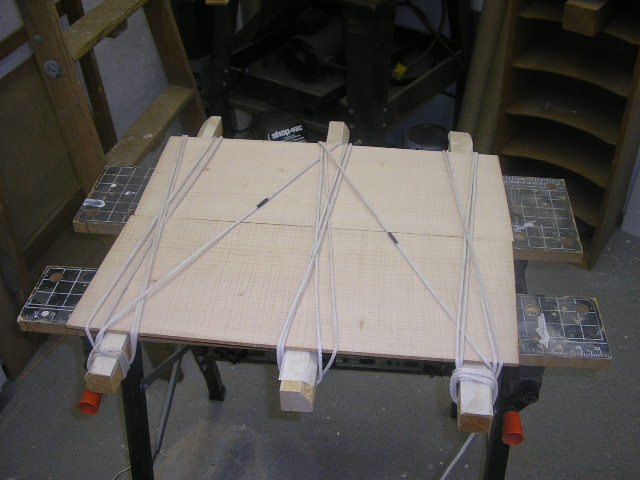

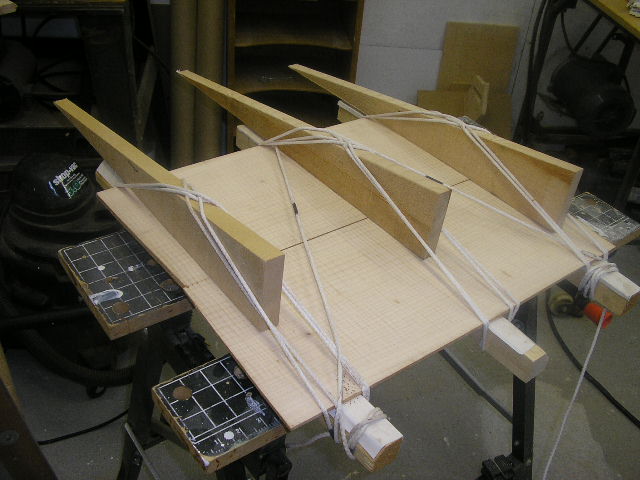

You mean this?

|

|

| Author: | Don Williams [ Mon Nov 07, 2005 7:35 am ] |

| Post subject: | |

I tried that method...it was more trouble than I wanted to have. I went back to the simple wedge method, with weight on top as per Cumpiano & Natelson. So much easier... for me. |

|

| Author: | PaulB [ Mon Nov 07, 2005 11:34 am ] |

| Post subject: | |

Hesh, thanks for asking this question, I've been going to ask about this method for ages. There must be a secret to it. By the time I got all that rope on, the glue would be dry and it'd be time to un-clamp. |

|

| Author: | Rod True [ Mon Nov 07, 2005 5:57 pm ] |

| Post subject: | |

There is no secret to this method, it just uses the wedge to tighten up the rope. Also the dimensions of the slats and wedges are not critical. I think as long as the wedge is wide enough, 1" or better and the slate about the same or slightly more, you'll have no problems. For my slats, I just used what ever scrap 2x2 I had lying around and the wedges I made out of scrap fir, 4" x 18" cut on the diagonal gives me two of them. Of course, like all joining methods, you need to have the plates candled well to have a good join. I have mocked up some pics to try and help out. Start with the slats on a workmate or some other surface that will allow you to get at each end of the slat.

Tie one end of your rope to one end of one of the slats. Now run a bead of glue down the middle of the plates to be joined, and run your finger along the seam to spread the glue.

Now open up the plates and set them on the slats.

Now start to criss cross the rope over the plate like so,

Move your way along the plate and the slats, criss crossing about two times per slat.

Now, be sure to pull the rope tight to the edge of the plate and around each slat end, than push the wedges into place (YOU DON'T NEED A MALLET, JUST YOUR HAND WILL DO). Watch the glue squeeze out of the joint and you don't need much pressure for the joint if you've candled the plates well.

Ideally you want your wedges' to run from one edge of the plate to the other, not like my mock-up, but like John's The beauty of this method is that you don't need much room to store the "tools/clamps" and you can just stand it on edge against the wall, out of the way to do the next plate, just need more wedges, slats and rope. Very simple and inexpensive. Try it out, you'll find your own sequence and method to this madness. Some tips: make sure you have wax paper on your wedge and slat, or they will become part of the plate, and I'm sure they will add to much weight and end up damping the plate.  |

|

| Author: | PaulB [ Mon Nov 07, 2005 7:24 pm ] |

| Post subject: | |

Excellent, thanks, just what I wanted to know. I always thought the Cumpiano method was a little cumbersome, and took up too much bench space. So using hide glue with this method is ok in terms of getting it all setup before the glue gets cold? |

|

| Author: | RussellR [ Mon Nov 07, 2005 7:48 pm ] |

| Post subject: | |

Hello Guys I use a variation of this, on this version the strings with the bottom runners are fixed to a board.

|

|

| Author: | Colin S [ Mon Nov 07, 2005 8:47 pm ] |

| Post subject: | |

OK, so why would anyone want to be bothered with all this malarkey when a few bits of sticky tape and a brick is all that's needed for the Tent method (often discussed here) which works perfectly? Why overcomplicate a process? Colin |

|

| Author: | RussellR [ Mon Nov 07, 2005 9:40 pm ] |

| Post subject: | |

It a word Colin Throughput, I agree the tape method is great, but problem is I can't move it while it sets, Often I'll have 10 plates to join, so I have a number of these jigs, when the plates are in I can move them and stack them. |

|

| Author: | Arnt Rian [ Mon Nov 07, 2005 10:50 pm ] |

| Post subject: | |

I use the Cumpiano method with little wedges against a stop on a board (like Don W). It can be moved and stacked out of the way too. |

|

| Author: | RussellR [ Mon Nov 07, 2005 10:57 pm ] |

| Post subject: | |

Hello Colin Are you back in the UK yet ? If you are Welcome Home |

|

| Author: | Michael Dale Payne [ Tue Nov 08, 2005 1:20 am ] |

| Post subject: | |

I have a 22” wide x 30” long 5/8 ply board with non stick tape down where the center seam will be and a 1" eye bolt at opposite end of the seam. There are 4 screw clamps on one side attached to a push board that press the planks together, and a clamped stop on the other side . I insert a 7/8 diameter steel round bar in the eye bolts and use 6 wood wedges to compress between the round bar and the seam from alternating directions. Works the same as the rope does but I don't have to wind the rope. I insert a 1/16 thick shim under the seam till the wedges are engaged to hand tight remove the shim and tighten the wedges. |

|

| Author: | John How [ Tue Nov 08, 2005 2:24 am ] |

| Post subject: | |

Colin, I do this because it is the method I learned and I enjoy it. |

|

| Author: | L. Presnall [ Tue Nov 08, 2005 2:29 am ] |

| Post subject: | |

"Non-stick tape"...seems like a contradiction in terms!  Like "Jumbo Shrimp" or "Airline Management"...I just use 3 Pony furniture clamps left over from the cabinetry days...leave my top/back thick and barely apply clamping pressure...the extra thickness prevents the top/back wanting to "bow up" in the middle....but the wedge thing is so "old world" and elegant... Like "Jumbo Shrimp" or "Airline Management"...I just use 3 Pony furniture clamps left over from the cabinetry days...leave my top/back thick and barely apply clamping pressure...the extra thickness prevents the top/back wanting to "bow up" in the middle....but the wedge thing is so "old world" and elegant...

|

|

| Author: | L. Presnall [ Tue Nov 08, 2005 3:18 am ] |

| Post subject: | |

Hesh, If it'll make you feel better about the hammer/mallet thing, check out the bottom photos on this page regarding how they do things up in Canada! http://www.proulxguitars.com/buildup/build11.htm

|

|

| Author: | Michael Dale Payne [ Tue Nov 08, 2005 3:29 am ] |

| Post subject: | |

[QUOTE=MichaelP] I have a 22” wide x 30” long 5/8 ply board with non stick tape down where the center seam will be and a 1" eye bolt at opposite end of the seam. There are 4 screw clamps on one side attached to a push board that press the planks together, and a clamped stop on the other side . I insert a 7/8 diameter steel round bar in the eye bolts and use 6 wood wedges to compress between the round bar and the seam from alternating directions. Works the same as the rope does but I don't have to wind the rope. I insert a 1/16 thick shim under the seam till the wedges are engaged to hand tight remove the shim and tighten the wedges.[/QUOTE] Just to be clearHere is a quick sketch

|

|

| Author: | Michael Dale Payne [ Tue Nov 08, 2005 3:51 am ] |

| Post subject: | |

non-stick tape, one side is teflon coated we use it here at work |

|

| Author: | Rod True [ Tue Nov 08, 2005 7:58 am ] |

| Post subject: | |

Larry, we don't all do things like that up here in the great white north you know, some of use use chainsaws for cutting veneers  . Mario is part lumberjack I think. . Mario is part lumberjack I think.

He sure makes a nice guitar though. |

|

| Author: | jfrench [ Tue Nov 08, 2005 10:16 am ] |

| Post subject: | |

Geez... I'm with Colin. While I like the way all this old world wedge stuff looks, save yourself some pain and try the tent method or this: Make two straight boards, out of some scrap neck blanks or whatever. Before you Joint the center, joint the outside edges so the upper bout area has 10mm+ (overall) less width than the lower bout. Joint the center accordingly. Now clamp the scrap straight boards to a flat workboard, and put your soundboard/back against them to make the proper "wedge". Put some wax paper down the center. Put glue between the boards, and put them together between the boards. If you want more pressure hammer them forward. The "wedge" creates the pressure at the center joint. Put weights on it to hold it down. This is a very straight forward, and very effective way to do this. I can't for the life of me understand why anyone would not want to blaze through joining plates at 100mph instead of introducing all these elaborate solutions for simple problems.... |

|

| Author: | Rod True [ Tue Nov 08, 2005 12:47 pm ] |

| Post subject: | |

Geez, As John said and I agree, I realy like the idea of being able to glue up the plate and set it off my bench so I can do something else on that surface for the hour it takes to set up the glue. Besides, there is less material required to make the simple "old world wedge" method than any other method which can be portable. No need for clamps, large work boards with 20+" long edges boards, clamped or screwed to it, no need for weights. I am not saying that other methods do not work, I am just supporting the method which works well for me. It is not painfull or slow, it is very efficient in all aspects of the task. As far as blazing through joining plates, it only takes me a minute or two once I have the plates candled to glue it up, I'm sure none of us here are counting seconds on our build time as none of us are factories. Remember there are several ways to skin a cat (sorry to those who like cats, we are talking about luthiery) and one way is not necessarily better than the other. |

|

| Author: | John How [ Tue Nov 08, 2005 1:27 pm ] |

| Post subject: | |

[QUOTE=jfrench] Geez... [/QUOTE] Not all boards we use for making guitars have nice straight outside edges, at least in my wood pile. Some of them are barely big enough to make a guitar and have to be jointed carefully and sparingley just to have enough wood. With my rope and wedge system I can do all sizes and shapes with the same jig and it conforms very nicely. I'll bet I can do it just as fast and easy as any other method as well. I even use the stretchy tape method when I feel like it, mostly when bookmatching some wood to use for a headplate or rosette. |

|

| Author: | Colin S [ Tue Nov 08, 2005 9:02 pm ] |

| Post subject: | |

[QUOTE=RussellR] It a word Colin Throughput, I agree the tape method is great, but problem is I can't move it while it sets, Often I'll have 10 plates to join, so I have a number of these jigs, when the plates are in I can move them and stack them. [/QUOTE] As soon as the glue goes to leathery state (10mins) I scrape it off and stand the plates leaning against the wall at the back of the bench to harden and can get on with the next set. Basically you can glue plates together as fast as you can joint them. The best guide in any endevour is to use the lowest level of technology that will get the job done. Ten bits of tape is about a low a technology as you can get. Colin PS Yes I'm back in England, got home yesterday. |

|

| Page 1 of 2 | All times are UTC - 5 hours |

| Powered by phpBB® Forum Software © phpBB Group http://www.phpbb.com/ |

|