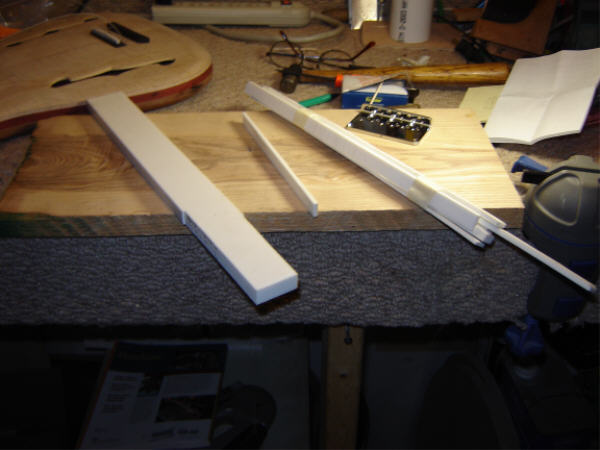

Here's some info I received from a professional guy who works with Corian, and BTW Martin Guitar uses Corian on some of their guitars.

"Cris, Corian is acrylic "ballasted" with marble

powder, although Corain is expensive at $350-$700 a

sheet it would be more expensive if it was solid

acrylic. The marble content accounts for the WEIGHT

of the material, it weighs just about as much as solid

stone.

Having said that, it works well with normal carbide

tooling. YES it's tougher to work than most wood.

Having said that he material is CONSISTENT which makes

it easier to work in some ways than wood, there's no

grain.

The typical Corian workshop uses a large radial arm

saw to cut down Corian sheets, then a normal 10" table

saw to cut it into strips. Individual Corian

fabricators are usually equipped with a 10" chop saw,

a 4 x 24" belt sander and an armada of 3 horsepower

routers. The primary router bits used are 1/2" single

flute, 1/2" double flute and 1" flush cutter. These

combined with various straight edges and jigs enable

the Corian fabricator to "carve" out a variety of

profiles. Edge detail is accomplished with smaller

routers like the Porter-Cable 690 series using 1/4"

roundover, 3/8" roundover or several different ogees.

That's for kitchen countertop fabrication...

For your purposes if you have a good bandsaw blade...

SAVE it! Corian will eat up your bandsaw blade twice

as fast as hardwood by my estimate. Having said that

it might not be too bad for the small amount of

material you need to cut. We cut down up to a hundred

10' sheets in a week, our notmal tool rotation is to

re-sharpen blades once a week.

Abrasives work quite well, coarse abrasives leave a

surprisingly smooth finish. Use a reciprocating

spindle sander if you've got one. For a recent

project we had to face a piece of millwork with 1/4"

Corian, instead of re-ordering 1/4" goods (1/2" is the

norm) the millworking contractor milled 1/2" material

down to 1/4" in their panel sander. an abrasive

planer does the same job."

CrowDuck

|

I like the sheeps horn idea though. Are there other alternatives such as, don't know, old marble tiles or other hard stuff that i would be able to use for this ?

I like the sheeps horn idea though. Are there other alternatives such as, don't know, old marble tiles or other hard stuff that i would be able to use for this ?