joe, I would need some really long cam clamps to go around the lenght of the body..

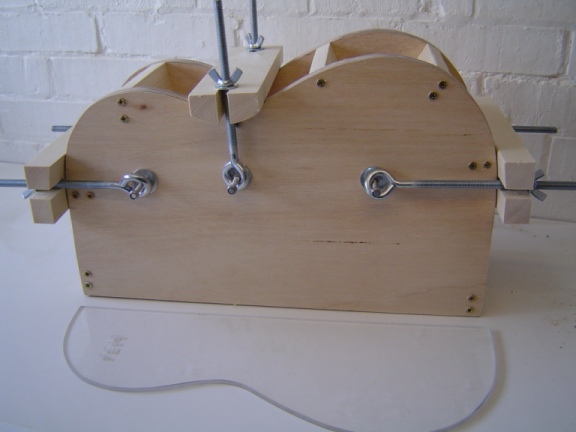

no seriously after I read Rods answer and waded through all of Marios wood it hit me.. cam clamps, or bar clamps, with anchors mounted in the main frame. Not sure if the guide post are needed in Marios bender. I was too tired to think about it after I made my way through the wood pile. But now I think maybe they would help as you pull in the waist to keep it aligned. Thanks guys tons of help there..

no seriously after I read Rods answer and waded through all of Marios wood it hit me.. cam clamps, or bar clamps, with anchors mounted in the main frame. Not sure if the guide post are needed in Marios bender. I was too tired to think about it after I made my way through the wood pile. But now I think maybe they would help as you pull in the waist to keep it aligned. Thanks guys tons of help there..