[QUOTE=Don A] [QUOTE=LanceK] I've never had any luck with planes, probably me. I use the stewmac leveling bars, I have the 18" IIRC? I put some 120 grit PA paper on the edge, clamp the two show sides together, place them on a piece of 1/4" ply, and clamp the whole thing down to my table saw, in less than a minute i get a perfect joint, I may have to hit it again, depending on how well they were matched before had. Using a jointer first is a good idea as Paul said, trouble is my joiner sucks![/QUOTE]

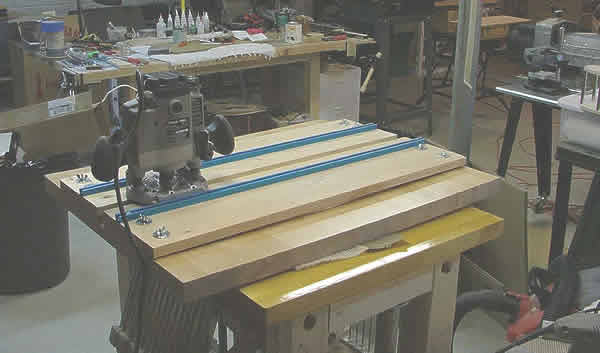

Anyone ever try using their router table?[/QUOTE]

I've heard of it being done and I've also talked to people who use their jointer, but my issue is that those are spinning blades and the cut you get is not as good as a well tuned hand plane. On my jointer I can see little ridges where it cut the piece and on a top joint you really want wood to wood contact with no gaps. I would use sandpaper before I used a jointer or a router for this.

But that's just my opinion

-Paul-

|

I rarly have to do this more than once or twice on harder woods. Does anyone have any thoughts on this problem?

I rarly have to do this more than once or twice on harder woods. Does anyone have any thoughts on this problem?

which is the hardest for me to cut, I just did a cocobolo set last night and I finally had to set the plane to take off minute amounts to keep the cocobolo from tearing on the edge but the whole process of getting the edges clean still only took about 10 minutes.

which is the hardest for me to cut, I just did a cocobolo set last night and I finally had to set the plane to take off minute amounts to keep the cocobolo from tearing on the edge but the whole process of getting the edges clean still only took about 10 minutes.