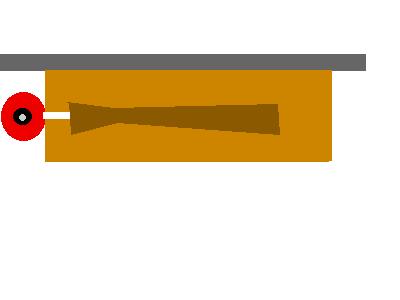

Brock, is the back of the neck profiled? If not, you could make a tapered piece, same as the taper on one side of the neck to create a reference edge parallel with the centerline of the neck, "tack" it in place, re-route your channel than cut the ledge off. That should work, if the back of the neck is still "squarish".

If not, who knows

sometimes its like you said "2 steps forward and 3 backwards"

sometimes its like you said "2 steps forward and 3 backwards"