Ow, sorry Af_one, I don't think it'll work

| Official Luthiers Forum! http://w-ww.luthiersforum.com/forum/ |

|

| a thought about fret presses. http://w-ww.luthiersforum.com/forum/viewtopic.php?f=10102&t=5832 |

Page 1 of 1 |

| Author: | af_one [ Sun Mar 26, 2006 12:37 pm ] |

| Post subject: | |

Why couldn't a fella take a fret caul and put it in a drill press to press the frets home. Unless theres somthing I'm overlooking it would seem like a cheap alternative to buying a press. Just build a neck support and lay on the press, adjust for height and press away? Can anyone shoot holes in this please? |

|

| Author: | Don A [ Sun Mar 26, 2006 12:44 pm ] |

| Post subject: | |

It will work. I know that Kathy Matsushita has used the same setup. Just be sure that you have a good drill press as the nylon gears in some cheaper models won't hold up. I first tried a Craftsman Universal Drill Press stand and stripped in out in short order. A good bench top drill press ought to do the trick. |

|

| Author: | Mario [ Sun Mar 26, 2006 12:52 pm ] |

| Post subject: | |

It's all I use... |

|

| Author: | Andy Zimmerman [ Sun Mar 26, 2006 1:01 pm ] |

| Post subject: | |

It is exactly what I do. I bought a 16 caul from stewmac and put it in my drill press. http://www.stewmac.com/shop/Fretting_supplies/Pressing/ Fret_Press_Caul.html |

|

| Author: | Pwoolson [ Sun Mar 26, 2006 1:21 pm ] |

| Post subject: | |

I do the same. I had a very cheap (Harbor Freight) drill press and the pressure of fretting made something inside go kind of whacky. So I now have a new one and the old drill press is my dedicated fret press. Works great. |

|

| Author: | old man [ Sun Mar 26, 2006 1:45 pm ] |

| Post subject: | |

That's what I do too. Works great. Ron |

|

| Author: | Rod True [ Sun Mar 26, 2006 5:15 pm ] |

| Post subject: | |

Ow, sorry Af_one, I don't think it'll work

|

|

| Author: | Rod True [ Sun Mar 26, 2006 5:29 pm ] |

| Post subject: | |

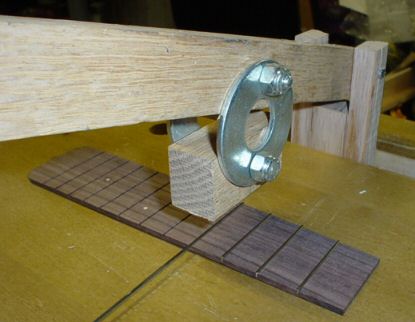

Here is a picture I remember from the MIMF of Dwain Wilder's fret press maybe this could be an easy alternative.  |

|

| Author: | 1bordeaux [ Sun Mar 26, 2006 11:59 pm ] |

| Post subject: | |

I use both; arbor press purchased through grizzly with the stew-mac ends, and sometimes the drill press for hard to reach areas/ instruments. |

|

| Author: | Todd Rose [ Mon Mar 27, 2006 5:43 am ] |

| Post subject: | |

I'm a bit leary. Using a tool/machine for something it wasn't designed to do... where's the emoticon that means "makes me a little nervous"? That kind of repeated pressure might (I repeat "might" because I really don't know) cause wear that would give you end-play in your drill press... or some other bad thing. |

|

| Author: | John Watkins [ Mon Mar 27, 2006 7:25 am ] |

| Post subject: | |

I have never used anything but a drill press. I like that I can feel resistance when something is not right. If all is well, I don't think it takes any more pressure than drilling a hole would. |

|

| Author: | Jim Watts [ Mon Mar 27, 2006 7:35 am ] |

| Post subject: | |

This my method also. No problems. |

|

| Author: | Mario [ Mon Mar 27, 2006 9:07 am ] |

| Post subject: | |

I must admit, I like the looks of that simple, home made press! Get the leverage ratio correct, and you can get plenty of power with that. Add a hook, and you can press the fret in, and leave it there under pressure while the glue cures, in the case of a problem fret/worn slot. Must to make.... thanks for posting that photo, Rod! Simple is what simple wants.... <g> |

|

| Author: | Rod True [ Mon Mar 27, 2006 9:10 am ] |

| Post subject: | |

Hey Mario, what if you made say 20 of these all ganged together, than you could do it all in one shot.

|

|

| Author: | L. Presnall [ Mon Mar 27, 2006 9:26 am ] |

| Post subject: | |

Don't give him any ideas!  You know he'll do it! You know he'll do it!

|

|

| Author: | TonyKarol [ Mon Mar 27, 2006 9:34 am ] |

| Post subject: | |

Just used my T-rex for the first time this morning - I used the bar clamp press for frets 1-14, then took the caul holder off the T-rex and used it in the drill press for frets 15-20. I fret with the board glued to the neck blank, so this worked excellent. |

|

| Author: | TomS [ Mon Mar 27, 2006 10:18 am ] |

| Post subject: | |

I made my own copy of Dwain Wilder's press and yes, it can develop more than enough pressure. And it has good tactile feedback when the fret seats. I'm not sure how the business end of Dwain's press is built. I made mine so the caul pivots and aligns with the fretboard, so that it bears evenly across the width of the fretboard. |

|

| Author: | Roy O [ Mon Mar 27, 2006 11:20 am ] |

| Post subject: | |

[QUOTE=TomS] I made my own copy of Dwain Wilder's press .... I made mine so the caul pivots and aligns with the fretboard, so that it bears evenly across the width of the fretboard.[/QUOTE] Would you post a picture or explain how you made it so your caul pivots? I've been thinking of making one of these but hadn't decided how I should make the caul pivot. TIA Roy |

|

| Author: | MSpencer [ Mon Mar 27, 2006 12:53 pm ] |

| Post subject: | |

I use the Drill press as well, works great Mike |

|

| Author: | TomS [ Mon Mar 27, 2006 10:11 pm ] |

| Post subject: | |

[QUOTE=Roy O] Would you post a picture or explain how you made it so your caul pivots? [/QUOTE] I made the fret press kind of on impulse one day so I just used what I had laying around. I used some left over oak flooring for the wood and some heavy washers to hold the 'caul'. The tops of the frets can leave an impression in the wood caul, which is fine if you can hit the same spot everytime. I didn't and ended up with an irregular surface on the oak block, so I added some hard purpleheart scraps, with the grain running 90 degrees to the frets, and this has held up well. Note that with my press, you do not want the washers to pivot on the top bolt. The nut on the top bolt is tight so that the washers are clamped against the handle. The lower bolt is tightened just enough so that the caul block does not flop around, but easily aligns to the fret surface. The handle is 30" long, and the caul is 4" from the handle pivot, so the lever ratio is 7.5:1. So far I have only used this for flat (non-radiused) fretboards. I did buy some of the S-M brass fret caul inserts for radiused boards. When I need to use them I'll make a block with a groove to hold the inserts. I have a plan to build a more "thought out" version of this press. I would use side plates that fasten or clamp rigidly to the handle instead of the washers. They could be made so that you can change the position along the handle, to adjust the leverage, but I doubt it's worth the effort. The caul block might be aluminum, with a slot and set screws to hold the S-M caul inserts. The sides of the caul block would taper at the bottom for better access to the fret. With my current press, I can't hold a fret in the slot and bring the caul down. I either have to start the fret in the slot by tapping it a little, or I don't cut the fret to length until after it's pressed in, as shown in one of the pictures below.

|

|

| Author: | Shane Neifer [ Tue Mar 28, 2006 2:26 am ] |

| Post subject: | |

I just bought a 1 ton arbor press from Busy Bee tools for $35 CDN. I drilled a hole for the Watkins caul and another for an allen screw to hold it in and it's done! I have two drill presses and I still use them for holes  . .

Shane |

|

| Author: | Rick Turner Gui [ Wed Mar 29, 2006 4:33 pm ] |

| Post subject: | |

Years ago I put a torque wrench on an arbor press so I could get a consistent indicator of how much pressure was being applied to each fret. Yes, each fingerboard may take a bit more or less pressure, but once you got used to the "click, click" of the torque wrench, it was easy enough to use. Now we just rely on human skill, but I may revisit that torque wrench thing some one of these days. |

|

| Page 1 of 1 | All times are UTC - 5 hours |

| Powered by phpBB® Forum Software © phpBB Group http://www.phpbb.com/ |

|