Although I have not figured out yet how to get a nice soft radius, I prefer the look and feel of something like this --

This by the way is a Mark Blanchard guitar

| Official Luthiers Forum! http://w-ww.luthiersforum.com/forum/ |

|

| How soft the binding edges? http://w-ww.luthiersforum.com/forum/viewtopic.php?f=10102&t=5996 |

Page 1 of 2 |

| Author: | Kelby [ Wed Apr 05, 2006 5:14 pm ] |

| Post subject: | |

I tend to just barely break the corner so they don't feel sharp (1/32" or 1/16" radius maybe), but I wonder how a more rounded edge would look and feel. How soft do you go? |

|

| Author: | tippie53 [ Wed Apr 05, 2006 10:51 pm ] |

| Post subject: | |

I go by feel. I like a softer edge after all its a guitar not a razor. Once I scrape the binding and I finish sand the top I use my thumb and hit the edges with the sandpaper to break the corner john hall |

|

| Author: | LanceK [ Wed Apr 05, 2006 10:57 pm ] |

| Post subject: | |

Although I have not figured out yet how to get a nice soft radius, I prefer the look and feel of something like this --

This by the way is a Mark Blanchard guitar |

|

| Author: | Rod True [ Thu Apr 06, 2006 1:00 am ] |

| Post subject: | |

You could use a round over bit

They make em as small as 1/16" radius Check out Rockler's roundover bits |

|

| Author: | L. Presnall [ Thu Apr 06, 2006 2:22 am ] |

| Post subject: | |

I like a scraper around the edge, followed by my thumb under some 220...

|

|

| Author: | Brad Goodman [ Thu Apr 06, 2006 2:53 am ] |

| Post subject: | |

I file a 45 degree bevel first,so I can judge how even it is, then two secondary bevels,then blend them together with 180 grit on a block,then 220 by had. |

|

| Author: | tl507362 [ Thu Apr 06, 2006 3:08 am ] |

| Post subject: | |

One of the local very experienced guitar builders(built over 300 guitars) uses a 1/8" roundover bit with a laminate trimmer. Last time I was in his shop he had just finished doing this. The edges were nice and soft, and 1/8" was perfect! Much so, that I'm thinking of selling the 1/8" roundover bit through Luthier Suppliers. I'm already talking to vendors now. I'll be doing a test on one very shortly. I'll let you know how it turns out. Hesh, also, good point on leaving the area under the fretboard extension untouched to give it better contact and no gaps. Tracy |

|

| Author: | LanceK [ Thu Apr 06, 2006 3:13 am ] |

| Post subject: | |

What I think I would like most about using a round over bit would be the consistency of the cut. The fear would be destroying a guitar that is so close to being done.

|

|

| Author: | peterm [ Thu Apr 06, 2006 3:24 am ] |

| Post subject: | |

I like to break the edge with a scraper and sandpaper and don't leave much of a radius on mine...just use my thumb to feel it out. But I do like the look of that Blanchard guitar....i'll try more radius next time

|

|

| Author: | CarltonM [ Thu Apr 06, 2006 7:46 am ] |

| Post subject: | |

Has anybody tried notching a scraper to an appropriate radius? |

|

| Author: | Kelby [ Thu Apr 06, 2006 8:01 am ] |

| Post subject: | |

I have always wanted to go with more of a radius, but never had the guts. It's easy to add more radius, hard to take it away. 1/8" radius sounds tempting. Any idea what the radius on the Blanchard guitar's bindings is, Lance? |

|

| Author: | Rod True [ Thu Apr 06, 2006 10:28 am ] |

| Post subject: | |

[QUOTE=LanceK] What I think I would like most about using a round over bit would be the consistency of the cut. The fear would be destroying a guitar that is so close to being done.

[/QUOTE] You could always do 2 passes, first with 1/16" than with 1/8" |

|

| Author: | LanceK [ Thu Apr 06, 2006 11:01 am ] |

| Post subject: | |

no idea what Mark uses? He probably uses his thumb and some mojo magic

His guitar oozzz class! |

|

| Author: | Don Williams [ Thu Apr 06, 2006 11:43 am ] |

| Post subject: | |

Having a stronger radius also helps the finish to adhere to the corners better. If sharp, the finish material would tend "pull away" from the corners. |

|

| Author: | paul harrell [ Thu Apr 06, 2006 12:45 pm ] |

| Post subject: | |

Carlton-I use a notched scraper and it works well. I use a round needle file to shape a notch at one corner of the scraper, and leave the burr from the file-quick and clean. Paul Harrell |

|

| Author: | Michael Dale Payne [ Fri Apr 07, 2006 1:18 am ] |

| Post subject: | |

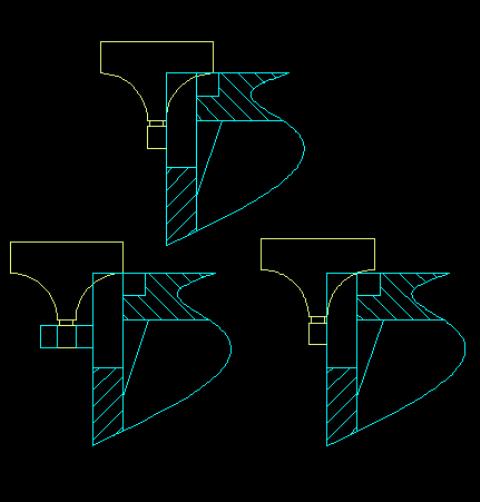

Be carful if your binding is .08 thick and you want to put an 1/8" radius on it with a roundover bit, you either need to inlarge the guide bearing dia. or set the depth of the bit higher than the router base or you will cut the radius past your binding and into your perfling or top/back. Here is three profiles showing what I mean, The top one is a 1/8" roundover bit in normal position. It will cut into the purfling. The other 2 are the fixes

I think raising the bit is the best. By the way you would need to rase the bit .009" for a 1/8" roundover bit on .08 binding. |

|

| Author: | Pete Licis [ Fri Apr 07, 2006 2:08 am ] |

| Post subject: | |

I like the radius on Mark Blanchards guitars. I think he may be radiusing them more nowadays, the one I own has a sharper radius. Mark does it by hand using eyeballing/feel with a file. |

|

| Author: | tl507362 [ Mon Apr 10, 2006 2:47 am ] |

| Post subject: | |

Hi all, I just wanted to update on everyone regarding the 1/8" roundover bit. I finally built up enough guts to put a laminate trimmer to the completed bouzouki body. Very scary thing to do, but it really worked out well. I first tested on scraps and measured how much the roundover would affect the purfling. I got mine set to not touch the purfling. Total setup time was about 10 minutes, and rounding over the binding edges for top and back were about 2 minutes. I stopped on the top where the fretboard meets the body so there will not be a gap under the fretboard. Here are some shots. The first one shows half of the binding rounded over(the binding that is closest to the lower bout has been rounded over, and the binding towards the upper bout had not been done yet). The second shot is of the round-over bit setting in my laminate trimmer. The 3rd is the completed binding. I highly recommend this way of rounding over. It is no more scary than routing your binding channels! I'll probably offer these bits on my website some time soon. Thanks! Tracy |

|

| Author: | Daniel M [ Mon Apr 10, 2006 7:05 am ] |

| Post subject: | |

Thanks for doing the work for us Tracy. I've been thinking about roundover bits for this job for quite a while, but haven't found a small enough bit yet. Looks like the 1/8" is about right. |

|

| Author: | BlueSpirit [ Mon Apr 10, 2006 10:44 am ] |

| Post subject: | |

Thanks Tracy. Let us know when you stock the bits. |

|

| Author: | SimonF [ Mon Apr 10, 2006 2:54 pm ] |

| Post subject: | |

Just noticed this thread - I have been using a 1/8" roundover bit in my Ribbecke type binding jig for a while now. Warning: Just make sure you don't roundover where the fretboard will attach or you will have a gap there when you go to attach the neck. It gives the guitar a much better feel since you don't have a sharp edge at the binding. However, the 1/8" bit might be a bit to extreme for most folks - it has a tendency to eliminate the visibility of the binding when viewed face-on. Some pictures of the binding on my last build can be found at http://www.fayguitars.com/guitars/visuals/gallery.html |

|

| Author: | jfrench [ Tue Apr 11, 2006 1:56 am ] |

| Post subject: | |

I've always found that a well burnished scraper makes rounding the binding a fast and easy job. Accurate too. |

|

| Author: | CarltonM [ Tue Apr 11, 2006 7:21 am ] |

| Post subject: | |

[QUOTE=SimonF] [URL=http://www.fayguitars.com/guitars/visuals/gallery.html][/QUOTE] An interesting site, Simon. Your approach to some tasks reminded me that there's always another way--like using magnets to glue your side braces (cool!), and doing your soundhole radius on the router table (scary!). Do you use the same 1/8" bit as for your bindings? |

|

| Author: | SimonF [ Tue Apr 11, 2006 2:22 pm ] |

| Post subject: | |

I incorporate a cross-grain soundhole support - which basically makes the thickness around the soundhole twice (~0.225") what it would be normally. I then use a 1/16" roundover bit and finish it up with some sandpaper. A 1/8" bit will work on the first side but not on the second side - because you will have a curved surface where there needs to be a flat surface. Try it with your soundhole cutouts first. It isn't scary at all. The magnets work great - but get the strongest ones you can. I got quite a few really strong ceramic magnets at ACE for under $10. |

|

| Page 1 of 2 | All times are UTC - 5 hours |

| Powered by phpBB® Forum Software © phpBB Group http://www.phpbb.com/ |

|